Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

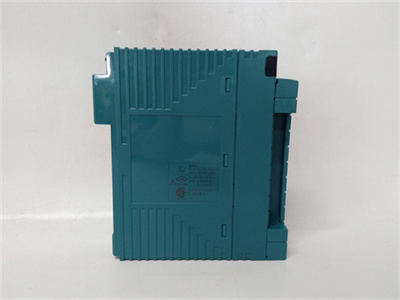

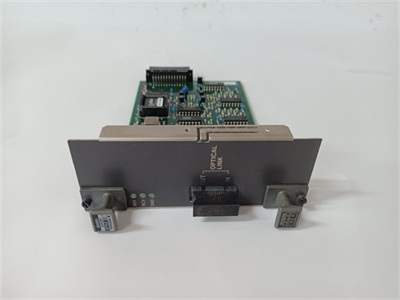

Yokogawa AIP532 ESB Bus Coupler Unit

Manufacturer:Yokogawa

Product Number:AIP532

Product Type:ESB Bus Coupler Unit

Origin:Japan

Dimensions:130 × 28 × 130 mm

Weight:0.15 kg

Views:35

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa AIP532 ESB Bus Coupler Unit is an advanced communication interface module designed to connect the Field Control Unit (FCU) of Yokogawa’s CENTUM VP Distributed Control System (DCS) to the ESB (Ethernet Subsystem Bus). Acting as a key communication bridge, the AIP532 enables seamless high-speed data exchange between control processors and I/O subsystems, ensuring stable and deterministic performance in mission-critical industrial environments.

The AIP532 is optimized for large-scale process automation, offering reliable redundancy, error detection, and robust isolation. Its design focuses on enhanced system scalability, making it suitable for both new plant installations and modernization projects. With its strong integration capability, the AIP532 enhances the performance of CENTUM VP, ProSafe-RS, and STARDOM systems, ensuring a unified and resilient control backbone.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | AIP532 |

| Product Type | ESB Bus Coupler Unit |

| System Compatibility | CENTUM VP, ProSafe-RS integration |

| Communication Protocol | ESB Bus (Yokogawa proprietary high-speed Ethernet subsystem protocol) |

| Communication Speed | 100 Mbps deterministic communication |

| Redundancy | Dual redundant ESB connections with automatic switchover |

| Topology Support | Star and redundant bus structures |

| Isolation | Galvanic isolation between control processor and I/O bus |

| Diagnostics | Continuous self-checks, error detection, and alarm reporting |

| Error Detection | CRC and parity error handling with automatic recovery |

| Hot-Swap Capability | Supported in redundant systems |

| Power Supply | 24 VDC (±10%) |

| Power Consumption | Approx. 16–20 W |

| Operating Temperature | 0 °C to +55 °C (32 °F to 131 °F) |

| Storage Temperature | -20 °C to +70 °C (-4 °F to 158 °F) |

| Humidity | 5%–90% RH, non-condensing |

| Vibration Resistance | IEC/EN industrial-grade standards |

| EMC/EMI Compliance | Meets industrial noise immunity requirements |

| Dimensions | 130 × 28 × 130 mm |

| Weight | 0.15 kg |

Product Applications

The Yokogawa AIP532 ESB Bus Coupler Unit is widely used in high-reliability automation networks, where efficient control-to-I/O communication is essential. Applications include:

Process Control Networks: Linking control processors to I/O subsystems in CENTUM VP systems.

Safety Instrumented Systems (SIS): Connecting ProSafe-RS to field I/O with redundant communication paths.

Plant-Wide Integration: Providing reliable connectivity for large petrochemical, oil & gas, and power generation facilities.

Expansion Projects: Supporting scalable integration for additional I/O modules during plant upgrades.

Real-Time Monitoring: Ensuring deterministic communication for fast control loop execution.

Critical Infrastructure: Used in LNG terminals, offshore oil platforms, and power plants where downtime is unacceptable.

Product Advantages

High-Speed Communication: Provides deterministic, low-latency ESB communication for demanding control environments.

Redundant Operation: Dual communication paths ensure uninterrupted operation in case of failures.

Scalability: Supports seamless plant expansion and modernization without requiring major reconfiguration.

Hot-Swap Support: Allows replacement in redundant setups without impacting system availability.

Advanced Diagnostics: Self-checking and detailed alarm reporting improve troubleshooting efficiency.

Industrial Durability: Engineered to withstand harsh industrial conditions, including vibration and EMI.

Strong Isolation: Protects communication integrity by separating control processors from I/O subsystems.

System Integration: Designed for smooth connectivity with CENTUM VP and ProSafe-RS platforms.

FAQ

What is the primary role of the AIP532 in a Yokogawa system?

It serves as the coupler between the Field Control Unit and the ESB bus, enabling high-speed communication with I/O modules.

Does the AIP532 support redundant ESB communication?

Yes, it provides dual redundant ESB connections with automatic switchover.

Which systems are compatible with the AIP532?

It is compatible with CENTUM VP DCS and ProSafe-RS safety systems.

What communication protocol does the AIP532 use?

It uses Yokogawa’s proprietary ESB Bus protocol for deterministic Ethernet-based communication.

Is hot-swapping possible with the AIP532?

Yes, hot-swapping is supported when used in a redundant configuration.

How does the AIP532 ensure data integrity?

It employs CRC error detection, parity checks, and automatic error recovery mechanisms.

What kind of topology can be implemented with the AIP532?

It supports both star and redundant bus topologies.

How does the AIP532 contribute to system scalability?

It allows seamless expansion by coupling additional I/O modules without disrupting existing operations.

Does the AIP532 provide built-in diagnostics?

Yes, it continuously monitors itself and provides error/alarm reporting.

Can the AIP532 be used in safety-critical applications?

Yes, it is widely used with ProSafe-RS SIS in safety-critical environments such as oil & gas and power plants.

Yokogawa AIP532 ESB Bus Coupler Unit

Manufacturer:Yokogawa

Product Number:AIP532

Product Type:ESB Bus Coupler Unit

Origin:Japan

Dimensions:130 × 28 × 130 mm

Weight:0.15 kg

Views:35

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa AIP532 ESB Bus Coupler Unit is an advanced communication interface module designed to connect the Field Control Unit (FCU) of Yokogawa’s CENTUM VP Distributed Control System (DCS) to the ESB (Ethernet Subsystem Bus). Acting as a key communication bridge, the AIP532 enables seamless high-speed data exchange between control processors and I/O subsystems, ensuring stable and deterministic performance in mission-critical industrial environments.

The AIP532 is optimized for large-scale process automation, offering reliable redundancy, error detection, and robust isolation. Its design focuses on enhanced system scalability, making it suitable for both new plant installations and modernization projects. With its strong integration capability, the AIP532 enhances the performance of CENTUM VP, ProSafe-RS, and STARDOM systems, ensuring a unified and resilient control backbone.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | AIP532 |

| Product Type | ESB Bus Coupler Unit |

| System Compatibility | CENTUM VP, ProSafe-RS integration |

| Communication Protocol | ESB Bus (Yokogawa proprietary high-speed Ethernet subsystem protocol) |

| Communication Speed | 100 Mbps deterministic communication |

| Redundancy | Dual redundant ESB connections with automatic switchover |

| Topology Support | Star and redundant bus structures |

| Isolation | Galvanic isolation between control processor and I/O bus |

| Diagnostics | Continuous self-checks, error detection, and alarm reporting |

| Error Detection | CRC and parity error handling with automatic recovery |

| Hot-Swap Capability | Supported in redundant systems |

| Power Supply | 24 VDC (±10%) |

| Power Consumption | Approx. 16–20 W |

| Operating Temperature | 0 °C to +55 °C (32 °F to 131 °F) |

| Storage Temperature | -20 °C to +70 °C (-4 °F to 158 °F) |

| Humidity | 5%–90% RH, non-condensing |

| Vibration Resistance | IEC/EN industrial-grade standards |

| EMC/EMI Compliance | Meets industrial noise immunity requirements |

| Dimensions | 130 × 28 × 130 mm |

| Weight | 0.15 kg |

Product Applications

The Yokogawa AIP532 ESB Bus Coupler Unit is widely used in high-reliability automation networks, where efficient control-to-I/O communication is essential. Applications include:

Process Control Networks: Linking control processors to I/O subsystems in CENTUM VP systems.

Safety Instrumented Systems (SIS): Connecting ProSafe-RS to field I/O with redundant communication paths.

Plant-Wide Integration: Providing reliable connectivity for large petrochemical, oil & gas, and power generation facilities.

Expansion Projects: Supporting scalable integration for additional I/O modules during plant upgrades.

Real-Time Monitoring: Ensuring deterministic communication for fast control loop execution.

Critical Infrastructure: Used in LNG terminals, offshore oil platforms, and power plants where downtime is unacceptable.

Product Advantages

High-Speed Communication: Provides deterministic, low-latency ESB communication for demanding control environments.

Redundant Operation: Dual communication paths ensure uninterrupted operation in case of failures.

Scalability: Supports seamless plant expansion and modernization without requiring major reconfiguration.

Hot-Swap Support: Allows replacement in redundant setups without impacting system availability.

Advanced Diagnostics: Self-checking and detailed alarm reporting improve troubleshooting efficiency.

Industrial Durability: Engineered to withstand harsh industrial conditions, including vibration and EMI.

Strong Isolation: Protects communication integrity by separating control processors from I/O subsystems.

System Integration: Designed for smooth connectivity with CENTUM VP and ProSafe-RS platforms.

FAQ

What is the primary role of the AIP532 in a Yokogawa system?

It serves as the coupler between the Field Control Unit and the ESB bus, enabling high-speed communication with I/O modules.

Does the AIP532 support redundant ESB communication?

Yes, it provides dual redundant ESB connections with automatic switchover.

Which systems are compatible with the AIP532?

It is compatible with CENTUM VP DCS and ProSafe-RS safety systems.

What communication protocol does the AIP532 use?

It uses Yokogawa’s proprietary ESB Bus protocol for deterministic Ethernet-based communication.

Is hot-swapping possible with the AIP532?

Yes, hot-swapping is supported when used in a redundant configuration.

How does the AIP532 ensure data integrity?

It employs CRC error detection, parity checks, and automatic error recovery mechanisms.

What kind of topology can be implemented with the AIP532?

It supports both star and redundant bus topologies.

How does the AIP532 contribute to system scalability?

It allows seamless expansion by coupling additional I/O modules without disrupting existing operations.

Does the AIP532 provide built-in diagnostics?

Yes, it continuously monitors itself and provides error/alarm reporting.

Can the AIP532 be used in safety-critical applications?

Yes, it is widely used with ProSafe-RS SIS in safety-critical environments such as oil & gas and power plants.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...