Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

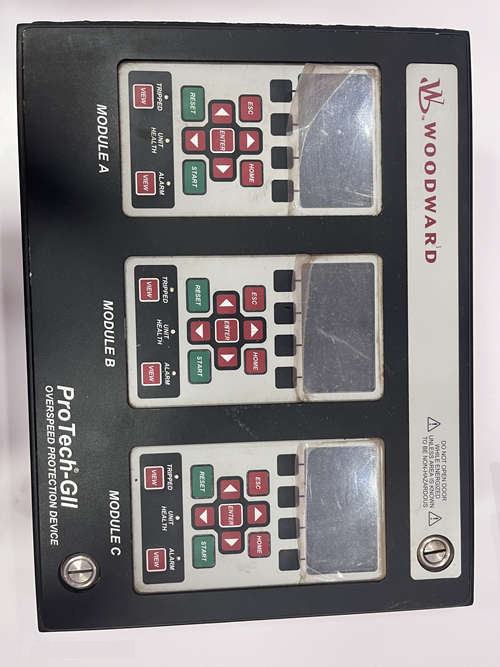

Woodward 9907-023 Direct Acting Speed Control Module

Manufacturer:Woodward

Product Number:9907-023

Product Type:Direct Acting Speed Control Module

Origin:USA

Dimensions:483 x 310 x 142 mm

Weight:2.27 kg

Views:146

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 9907-023 is a reliable and field-proven Direct Acting Speed Control Module engineered to regulate engine or turbine speed in industrial and prime power applications. Specifically designed for use with Woodward’s actuators, this control module delivers consistent speed regulation without the need for complex programming or high-level automation interfaces.

As part of Woodward’s EGC (Electronic Governor Control) family, the 9907-023 operates in direct-acting mode, meaning it uses the speed signal to control the actuator directly with minimal signal processing latency. This makes it ideal for medium- to high-speed engines, especially where simplicity, fast response, and reliability are essential.

Suitable for both droop and isochronous control modes, the 9907-023 is commonly found in generator sets, marine propulsion systems, compressors, and other industrial applications that require dependable speed stability across load ranges.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 9907-023 |

| Control Type | Direct Acting Speed Control |

| Compatible Engines | Diesel, Gas Engines, and Small Turbines |

| Speed Control Mode | Isochronous or Droop |

| Speed Sensing Input | Magnetic Pickup (MPU), 1–30 Vrms at 30–10,000 Hz |

| Speed Range | 500 to 10,000 RPM |

| Actuator Output | Current Driver Output (PWM/DC, typically 0–200 mA) |

| Response Time | <150 milliseconds |

| Power Supply Voltage | 18–32 VDC |

| Power Consumption | Typically <10 W |

| Gain and Stability Adjustments | Manual, via front-panel potentiometers |

| Operating Temperature | –40 °C to +85 °C (–40 °F to +185 °F) |

| Storage Temperature | –55 °C to +95 °C |

| Relative Humidity | 5–95%, non-condensing |

| Mounting Method | Panel or Chassis Mount |

| Status Indication | LED indicators for power and fault |

| Protections | Overspeed, actuator overload, reverse polarity |

| Compliance | CE, UL Recognized, CSA, RoHS Compliant |

| Dimensions | 483 x 310 x 142 mm |

| Weight | 2.27 kg |

Applications

The Woodward 9907-023 is widely adopted in applications where simple yet precise speed control is required:

Industrial Generator Sets: Maintains engine speed for consistent power frequency output.

Compressor Drives: Stabilizes speed for rotary screw or centrifugal compressors.

Marine Propulsion and Auxiliary Engines: Controls speed for efficient navigation or onboard systems.

Material Handling Equipment: Optimizes engine RPM for cranes, hoists, and heavy-duty lifting systems.

Pumping Stations: Regulates speed in water injection, fire, or oil transfer pumps.

OEM Equipment: Used by manufacturers seeking reliable engine speed control without needing PLCs or HMIs.

Advantages

Direct Acting Simplicity: Minimal setup required; speed signal is used to directly modulate the actuator.

Wide Engine Compatibility: Works with most mid-size diesel or gas engines in industrial use.

Fast Response: <150 ms response time allows tight control in fluctuating load environments.

Built-In Protection: Reverse polarity, overspeed, and actuator current limiting increase operational safety.

Flexible Mounting: Easily mounts to standard panels or enclosures.

Field-Adjustable Settings: On-unit potentiometers allow for fast gain and stability tuning.

No Software Needed: Fully hardware-configurable, ideal for remote or standalone installations.

Long-Term Durability: Designed with rugged components and wide operating temperature range.

Frequently Asked Questions (FAQ)

1. What is the main function of the 9907-023?

It provides closed-loop control of engine speed using a direct-acting method with an actuator.

2. Is the unit suitable for both diesel and gas engines?

Yes, it works with both diesel and natural gas-fueled internal combustion engines.

3. Does it support isochronous control?

Yes, the 9907-023 supports both isochronous and droop control modes.

4. What kind of actuator does it support?

It is designed for Woodward proportional actuators using PWM or DC current output.

5. Can it be used in marine environments?

Yes, with proper enclosure, it’s suitable for use in marine engine rooms or auxiliary systems.

6. How is the speed input provided?

Via a magnetic pickup (MPU) placed near the engine’s flywheel teeth or shaft.

7. Does it require external configuration software?

No, configuration is done using onboard potentiometers.

8. Is the module protected against wiring errors?

Yes, it features reverse polarity protection and actuator overload safeguards.

9. How is it mounted?

It can be mounted on a flat panel or chassis using standard screw holes.

10. Does it have a user interface or screen?

No, it uses LED indicators for status and requires no display or software interface.

Woodward 9907-023 Direct Acting Speed Control Module

Manufacturer:Woodward

Product Number:9907-023

Product Type:Direct Acting Speed Control Module

Origin:USA

Dimensions:483 x 310 x 142 mm

Weight:2.27 kg

Views:146

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 9907-023 is a reliable and field-proven Direct Acting Speed Control Module engineered to regulate engine or turbine speed in industrial and prime power applications. Specifically designed for use with Woodward’s actuators, this control module delivers consistent speed regulation without the need for complex programming or high-level automation interfaces.

As part of Woodward’s EGC (Electronic Governor Control) family, the 9907-023 operates in direct-acting mode, meaning it uses the speed signal to control the actuator directly with minimal signal processing latency. This makes it ideal for medium- to high-speed engines, especially where simplicity, fast response, and reliability are essential.

Suitable for both droop and isochronous control modes, the 9907-023 is commonly found in generator sets, marine propulsion systems, compressors, and other industrial applications that require dependable speed stability across load ranges.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 9907-023 |

| Control Type | Direct Acting Speed Control |

| Compatible Engines | Diesel, Gas Engines, and Small Turbines |

| Speed Control Mode | Isochronous or Droop |

| Speed Sensing Input | Magnetic Pickup (MPU), 1–30 Vrms at 30–10,000 Hz |

| Speed Range | 500 to 10,000 RPM |

| Actuator Output | Current Driver Output (PWM/DC, typically 0–200 mA) |

| Response Time | <150 milliseconds |

| Power Supply Voltage | 18–32 VDC |

| Power Consumption | Typically <10 W |

| Gain and Stability Adjustments | Manual, via front-panel potentiometers |

| Operating Temperature | –40 °C to +85 °C (–40 °F to +185 °F) |

| Storage Temperature | –55 °C to +95 °C |

| Relative Humidity | 5–95%, non-condensing |

| Mounting Method | Panel or Chassis Mount |

| Status Indication | LED indicators for power and fault |

| Protections | Overspeed, actuator overload, reverse polarity |

| Compliance | CE, UL Recognized, CSA, RoHS Compliant |

| Dimensions | 483 x 310 x 142 mm |

| Weight | 2.27 kg |

Applications

The Woodward 9907-023 is widely adopted in applications where simple yet precise speed control is required:

Industrial Generator Sets: Maintains engine speed for consistent power frequency output.

Compressor Drives: Stabilizes speed for rotary screw or centrifugal compressors.

Marine Propulsion and Auxiliary Engines: Controls speed for efficient navigation or onboard systems.

Material Handling Equipment: Optimizes engine RPM for cranes, hoists, and heavy-duty lifting systems.

Pumping Stations: Regulates speed in water injection, fire, or oil transfer pumps.

OEM Equipment: Used by manufacturers seeking reliable engine speed control without needing PLCs or HMIs.

Advantages

Direct Acting Simplicity: Minimal setup required; speed signal is used to directly modulate the actuator.

Wide Engine Compatibility: Works with most mid-size diesel or gas engines in industrial use.

Fast Response: <150 ms response time allows tight control in fluctuating load environments.

Built-In Protection: Reverse polarity, overspeed, and actuator current limiting increase operational safety.

Flexible Mounting: Easily mounts to standard panels or enclosures.

Field-Adjustable Settings: On-unit potentiometers allow for fast gain and stability tuning.

No Software Needed: Fully hardware-configurable, ideal for remote or standalone installations.

Long-Term Durability: Designed with rugged components and wide operating temperature range.

Frequently Asked Questions (FAQ)

1. What is the main function of the 9907-023?

It provides closed-loop control of engine speed using a direct-acting method with an actuator.

2. Is the unit suitable for both diesel and gas engines?

Yes, it works with both diesel and natural gas-fueled internal combustion engines.

3. Does it support isochronous control?

Yes, the 9907-023 supports both isochronous and droop control modes.

4. What kind of actuator does it support?

It is designed for Woodward proportional actuators using PWM or DC current output.

5. Can it be used in marine environments?

Yes, with proper enclosure, it’s suitable for use in marine engine rooms or auxiliary systems.

6. How is the speed input provided?

Via a magnetic pickup (MPU) placed near the engine’s flywheel teeth or shaft.

7. Does it require external configuration software?

No, configuration is done using onboard potentiometers.

8. Is the module protected against wiring errors?

Yes, it features reverse polarity protection and actuator overload safeguards.

9. How is it mounted?

It can be mounted on a flat panel or chassis using standard screw holes.

10. Does it have a user interface or screen?

No, it uses LED indicators for status and requires no display or software interface.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...