Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

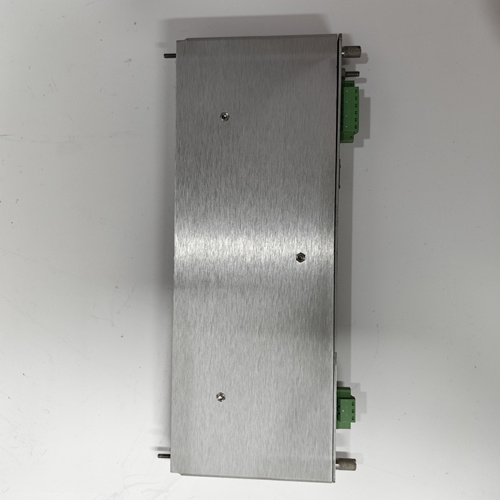

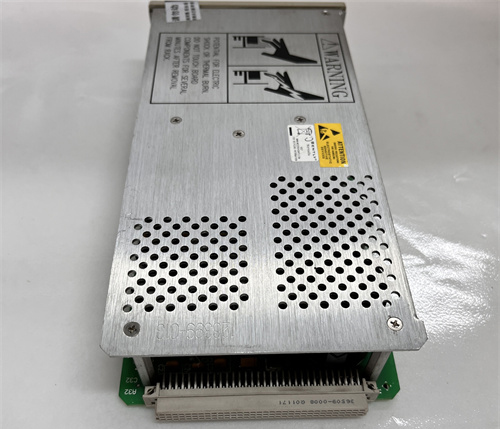

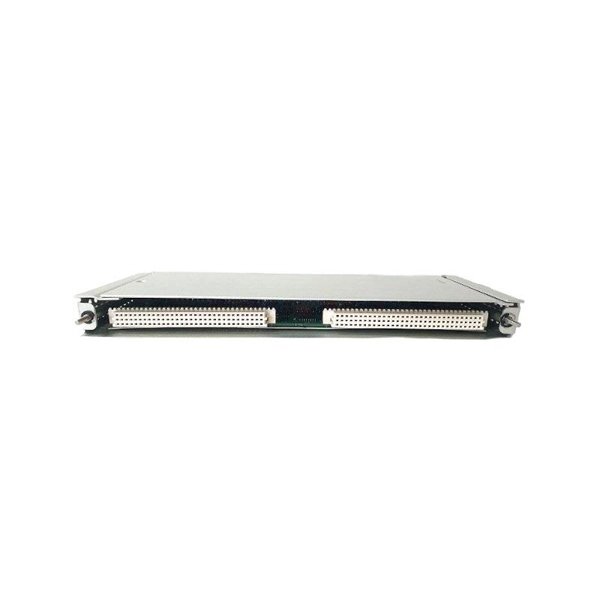

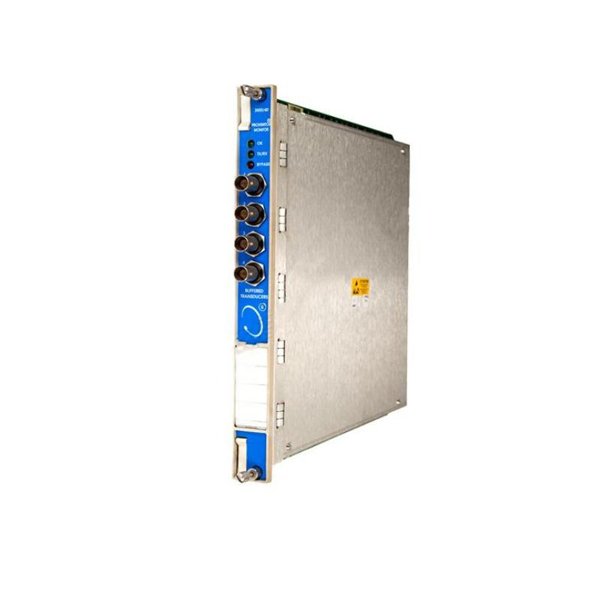

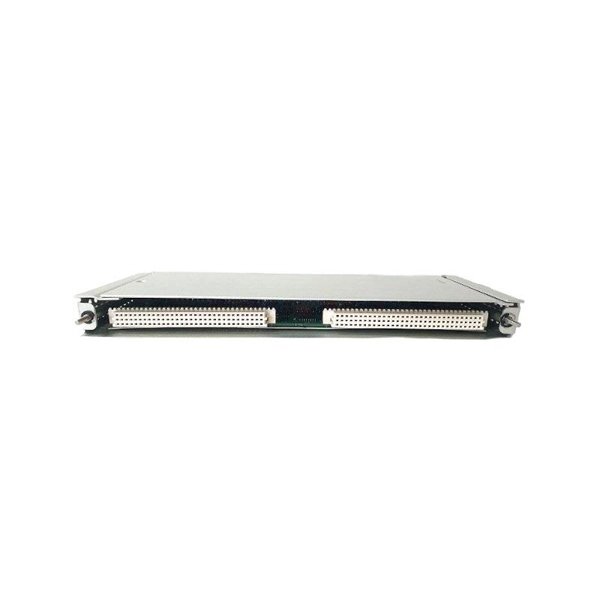

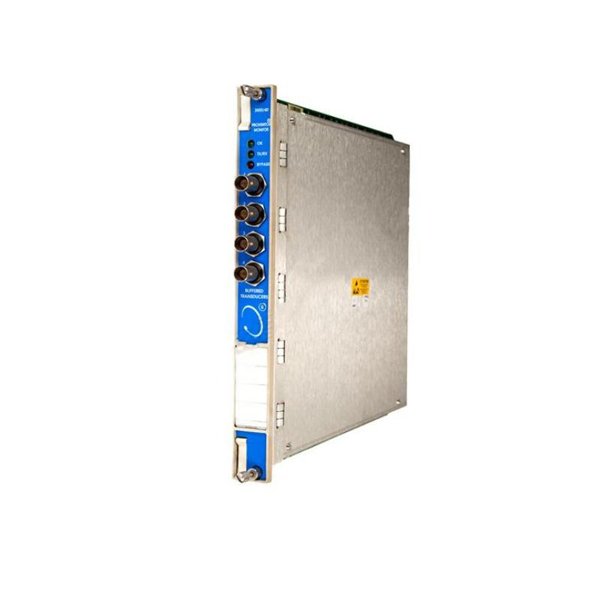

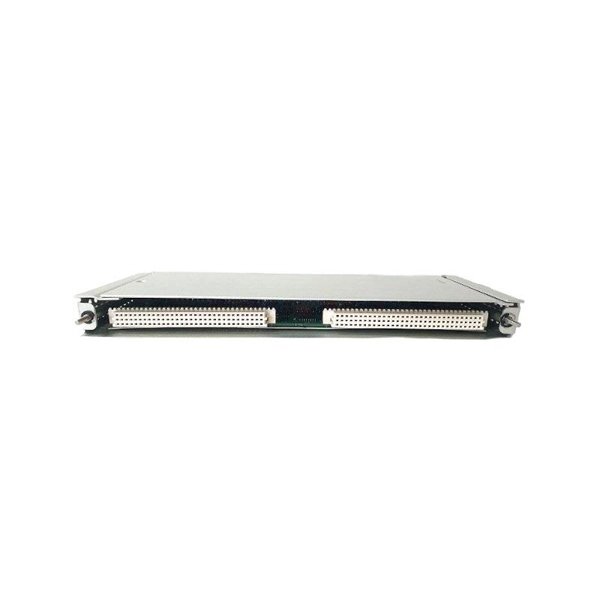

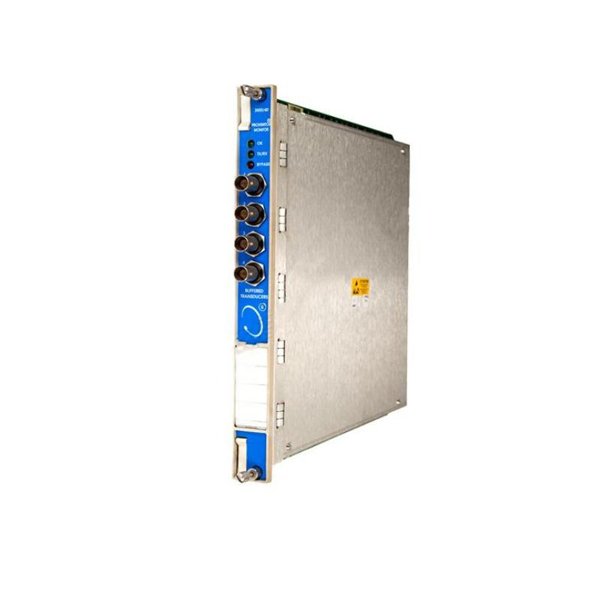

Bently Nevada 3500/42 140734-02 + 128240-01 Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42 140734-02+128240-01

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91kg

Views:31

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42 140734-02 + 128240-01 Proximitor Seismic Monitor is an essential component for monitoring seismic activity and vibrations in industrial machinery. As part of the Bently Nevada 3500 series, this device is specifically designed to detect abnormal seismic or vibration events that can lead to machinery malfunction or failure. The 3500/42 Seismic Monitor ensures early detection of potential problems, allowing operators to take corrective actions before significant damage occurs.

The 3500/42 is highly valued for its precision, reliability, and rugged design, making it ideal for deployment in industries where machinery integrity is crucial. Whether used in power plants, offshore oil rigs, mining operations, or manufacturing plants, the device delivers real-time data and alerts, helping to minimize downtime and extend the life of critical equipment.

Equipped with a NEMA 4X-rated enclosure, the 3500/42 is built to withstand harsh environmental conditions, ensuring uninterrupted operation even in challenging industrial environments. The system is designed to integrate seamlessly with other Bently Nevada monitoring devices, forming a comprehensive protection system for critical machinery.

Product Specifications

| Feature | Specification |

|---|---|

| Model Number | 3500/42 140734-02 + 128240-01 |

| Dimensions (L x W x H) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Power Supply | 24 VDC |

| Input Type | Seismic sensor input |

| Output Type | Digital (RS-485) |

| Operating Temperature | -40°C to 70°C |

| Humidity | 5% to 95% RH, non-condensing |

| Enclosure Rating | NEMA 4X |

| Signal Range | 4-20 mA, 0-10 VDC |

| Mounting Type | Panel mount |

Product Applications

The 3500/42 Proximitor Seismic Monitor has a wide range of applications in industries where equipment reliability is essential. It is specifically designed for:

Power Plants: Continuous monitoring of turbine and generator vibrations to ensure equipment health and prevent damage.

Oil & Gas: Seismic detection for offshore rigs and onshore operations, helping prevent equipment failure due to seismic disturbances.

Mining: Ensuring machinery stability in mining operations by detecting abnormal vibrations and seismic activities.

Manufacturing: Monitoring large industrial machines such as presses, rollers, and conveyors to prevent operational disruptions.

HVAC Systems: Detecting abnormal vibrations in HVAC systems, ensuring their efficient and safe operation.

Product Advantages

High-Precision Monitoring: Provides extremely accurate seismic and vibration data, enabling early detection of faults or anomalies in machinery.

Seamless Integration: Integrates smoothly with other Bently Nevada monitoring systems to create a unified machinery protection solution.

Durable and Reliable: With a NEMA 4X-rated enclosure, the 3500/42 is designed to endure extreme environmental conditions, including high humidity, dust, and harsh temperatures.

Real-Time Alerts: The system sends immediate notifications when seismic or vibration anomalies are detected, allowing operators to act quickly to avoid equipment damage.

Low Maintenance: Built to be maintenance-free for long periods, ensuring minimal downtime and operational efficiency.

Long-Term Operation: Designed for prolonged use in industrial settings, the device offers lasting reliability with reduced risk of failure.

FAQ (Frequently Asked Questions)

What is the function of the Bently Nevada 3500/42 Proximitor Seismic Monitor?

-

The 3500/42 is designed to monitor seismic activity and vibrations in machinery, detecting any abnormalities that could lead to mechanical failure.

-

What power supply is required for the 3500/42?

-

The 3500/42 requires a 24 VDC power supply.

-

What type of output does the 3500/42 provide?

-

The device provides a digital output via an RS-485 interface.

-

Can the 3500/42 be used outdoors?

-

Yes, with a NEMA 4X-rated enclosure, the 3500/42 is designed to function in outdoor and extreme environments.

-

What is the operating temperature range for the 3500/42?

-

The device can operate in temperatures ranging from -40°C to 70°C.

-

How is the 3500/42 mounted?

-

The 3500/42 is designed for panel mounting, making it easy to install in control panels.

-

Can the 3500/42 be integrated with other Bently Nevada products?

-

Yes, it integrates seamlessly with other Bently Nevada products for a comprehensive machinery monitoring and protection system.

-

What types of sensors can the 3500/42 support?

-

The 3500/42 supports seismic sensors with inputs such as 4-20 mA or 0-10 VDC.

-

Which industries benefit the most from using the 3500/42?

-

Power plants, oil & gas operations, mining industries, manufacturing facilities, and HVAC systems all benefit from the use of the 3500/42 seismic monitor.

-

What are the key benefits of using the 3500/42?

-

High accuracy, real-time alerts, durability, and long-term reliability in challenging industrial environments.

-

Bently Nevada 3500/42 140734-02 + 128240-01 Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42 140734-02+128240-01

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91kg

Views:31

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42 140734-02 + 128240-01 Proximitor Seismic Monitor is an essential component for monitoring seismic activity and vibrations in industrial machinery. As part of the Bently Nevada 3500 series, this device is specifically designed to detect abnormal seismic or vibration events that can lead to machinery malfunction or failure. The 3500/42 Seismic Monitor ensures early detection of potential problems, allowing operators to take corrective actions before significant damage occurs.

The 3500/42 is highly valued for its precision, reliability, and rugged design, making it ideal for deployment in industries where machinery integrity is crucial. Whether used in power plants, offshore oil rigs, mining operations, or manufacturing plants, the device delivers real-time data and alerts, helping to minimize downtime and extend the life of critical equipment.

Equipped with a NEMA 4X-rated enclosure, the 3500/42 is built to withstand harsh environmental conditions, ensuring uninterrupted operation even in challenging industrial environments. The system is designed to integrate seamlessly with other Bently Nevada monitoring devices, forming a comprehensive protection system for critical machinery.

Product Specifications

| Feature | Specification |

|---|---|

| Model Number | 3500/42 140734-02 + 128240-01 |

| Dimensions (L x W x H) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Power Supply | 24 VDC |

| Input Type | Seismic sensor input |

| Output Type | Digital (RS-485) |

| Operating Temperature | -40°C to 70°C |

| Humidity | 5% to 95% RH, non-condensing |

| Enclosure Rating | NEMA 4X |

| Signal Range | 4-20 mA, 0-10 VDC |

| Mounting Type | Panel mount |

Product Applications

The 3500/42 Proximitor Seismic Monitor has a wide range of applications in industries where equipment reliability is essential. It is specifically designed for:

Power Plants: Continuous monitoring of turbine and generator vibrations to ensure equipment health and prevent damage.

Oil & Gas: Seismic detection for offshore rigs and onshore operations, helping prevent equipment failure due to seismic disturbances.

Mining: Ensuring machinery stability in mining operations by detecting abnormal vibrations and seismic activities.

Manufacturing: Monitoring large industrial machines such as presses, rollers, and conveyors to prevent operational disruptions.

HVAC Systems: Detecting abnormal vibrations in HVAC systems, ensuring their efficient and safe operation.

Product Advantages

High-Precision Monitoring: Provides extremely accurate seismic and vibration data, enabling early detection of faults or anomalies in machinery.

Seamless Integration: Integrates smoothly with other Bently Nevada monitoring systems to create a unified machinery protection solution.

Durable and Reliable: With a NEMA 4X-rated enclosure, the 3500/42 is designed to endure extreme environmental conditions, including high humidity, dust, and harsh temperatures.

Real-Time Alerts: The system sends immediate notifications when seismic or vibration anomalies are detected, allowing operators to act quickly to avoid equipment damage.

Low Maintenance: Built to be maintenance-free for long periods, ensuring minimal downtime and operational efficiency.

Long-Term Operation: Designed for prolonged use in industrial settings, the device offers lasting reliability with reduced risk of failure.

FAQ (Frequently Asked Questions)

What is the function of the Bently Nevada 3500/42 Proximitor Seismic Monitor?

-

The 3500/42 is designed to monitor seismic activity and vibrations in machinery, detecting any abnormalities that could lead to mechanical failure.

-

What power supply is required for the 3500/42?

-

The 3500/42 requires a 24 VDC power supply.

-

What type of output does the 3500/42 provide?

-

The device provides a digital output via an RS-485 interface.

-

Can the 3500/42 be used outdoors?

-

Yes, with a NEMA 4X-rated enclosure, the 3500/42 is designed to function in outdoor and extreme environments.

-

What is the operating temperature range for the 3500/42?

-

The device can operate in temperatures ranging from -40°C to 70°C.

-

How is the 3500/42 mounted?

-

The 3500/42 is designed for panel mounting, making it easy to install in control panels.

-

Can the 3500/42 be integrated with other Bently Nevada products?

-

Yes, it integrates seamlessly with other Bently Nevada products for a comprehensive machinery monitoring and protection system.

-

What types of sensors can the 3500/42 support?

-

The 3500/42 supports seismic sensors with inputs such as 4-20 mA or 0-10 VDC.

-

Which industries benefit the most from using the 3500/42?

-

Power plants, oil & gas operations, mining industries, manufacturing facilities, and HVAC systems all benefit from the use of the 3500/42 seismic monitor.

-

What are the key benefits of using the 3500/42?

-

High accuracy, real-time alerts, durability, and long-term reliability in challenging industrial environments.

-

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...