Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

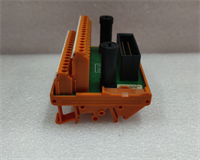

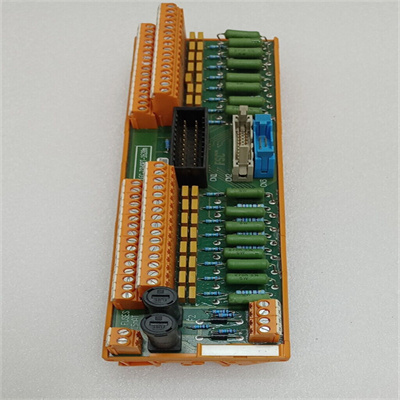

Honeywell 621-0071 Logic Manager Module

Manufacturer:Honeywell

Product Number:621-0071

Product Type:Logic Manager Module

Origin:USA

Dimensions:50 x 130 x 160 mm

Weight:0.52 kg

Views:47

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 621-0071 Logic Manager Module is a core component of Honeywell’s TDC 2000/3000 Distributed Control Systems (DCS), serving as a high-reliability logic processing unit. Designed to execute discrete and sequential control strategies, the 621-0071 enables deterministic, high-speed logic operations essential to critical plant operations.

This module acts as a central controller in systems that require rapid decision-making, event handling, and interlock processing. It communicates seamlessly with I/O modules and other system processors through the Honeywell Universal Control Network (UCN), ensuring robust and timely data exchange.

Ideal for applications involving interlocks, equipment protection, and sequence control, the 621-0071 is a foundational logic processor in the Honeywell control ecosystem. With built-in diagnostics, high-speed logic execution, and integration with the PlantScape and TDC platforms, it delivers reliability, flexibility, and long-term support in industrial environments.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | 621-0071 |

| Module Type | Logic Manager Module |

| Function | Executes discrete and sequential logic operations |

| Communication Interface | Universal Control Network (UCN) |

| Control Strategy Type | Ladder logic, Boolean expressions, sequential control |

| Execution Time | <10 ms for typical logic scans |

| Internal Diagnostics | Yes – error logging, watchdog, and self-test |

| Input Types | Binary inputs (via digital input modules) |

| Output Types | Binary outputs (via digital output modules) |

| Programming Environment | Honeywell Logic Manager configuration tools |

| Power Source | Via backplane supply |

| Power Consumption | Approx. 5.5W |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C (-40°F to 185°F) |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Mounting | DIN rail or Honeywell system backplane |

| Dimensions (W x H x D) | 50 x 130 x 160 mm |

| Weight | 0.52 kg |

| Compliance/Certifications | CE, UL, RoHS, ISA compliant |

| System Compatibility | Honeywell TDC 2000, TDC 3000, PlantScape |

Applications

The 621-0071 Logic Manager Module is purpose-built for executing logic operations in process automation. Its wide adoption across industries underscores its versatility and reliability. Common application areas include:

Power Generation

Turbine interlock logic, breaker control, and emergency shutdown sequences.

Oil & Gas Processing

Logic for safety interlocks, pump control, and flare system coordination.

Petrochemical Plants

Execution of batch sequences, process step logic, and system alarms.

Water and Wastewater

Valve sequencing, pump alternation logic, and tank level interlocks.

Pharmaceutical Manufacturing

Batch control steps, validation interlocks, and compliance sequences.

Pulp and Paper

Boiler logic control, paper machine startup/shutdown procedures.

Key Advantages

Fast and Deterministic Logic Execution

Delivers sub-10 ms logic scan times, critical for high-speed interlocking and control.

Integrated with Honeywell DCS

Seamless operation with TDC 2000/3000 and PlantScape systems via UCN.

Built-in Diagnostics

Monitors logic execution, reports system health, and logs internal faults.

Compact and Durable Design

Industrial-grade module built to withstand demanding plant environments.

Flexible Logic Programming

Supports ladder diagrams, Boolean logic, and complex control sequences.

Reduces Downtime

High availability design with robust error recovery and logic persistence.

Field-Proven Reliability

Long lifecycle and wide deployment in mission-critical control systems worldwide.

Frequently Asked Questions (FAQ)

What is the primary function of the 621-0071 module?

It processes discrete and sequential control logic, often used for interlocks, machine control, and sequencing.

Does it support real-time logic processing?

Yes, it delivers high-speed deterministic logic execution with response times typically under 10 ms.

How is it configured?

Logic is developed using Honeywell’s configuration tools (e.g., Logic Manager or UCN-configurable environments).

Can it be used in redundant configurations?

While redundancy may be supported at a system level, the 621-0071 is typically deployed as a single logic controller per unit operation.

Is the module hot-swappable?

It’s recommended to power down the system or isolate the segment before removing or replacing the module.

What types of signals does it process?

It handles digital (binary) inputs and outputs via separate I/O modules connected through the control system.

What Honeywell systems is it compatible with?

Fully compatible with TDC 2000, TDC 3000, and PlantScape systems.

Does it include error logging?

Yes, onboard diagnostics track execution errors, communication faults, and system status.

What kind of logic can I program into it?

Ladder logic, Boolean expressions, and custom sequential control steps.

How is communication handled with other system elements?

Through the Universal Control Network (UCN), allowing integration with I/O modules and higher-level controllers.

Honeywell 621-0071 Logic Manager Module

Manufacturer:Honeywell

Product Number:621-0071

Product Type:Logic Manager Module

Origin:USA

Dimensions:50 x 130 x 160 mm

Weight:0.52 kg

Views:47

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 621-0071 Logic Manager Module is a core component of Honeywell’s TDC 2000/3000 Distributed Control Systems (DCS), serving as a high-reliability logic processing unit. Designed to execute discrete and sequential control strategies, the 621-0071 enables deterministic, high-speed logic operations essential to critical plant operations.

This module acts as a central controller in systems that require rapid decision-making, event handling, and interlock processing. It communicates seamlessly with I/O modules and other system processors through the Honeywell Universal Control Network (UCN), ensuring robust and timely data exchange.

Ideal for applications involving interlocks, equipment protection, and sequence control, the 621-0071 is a foundational logic processor in the Honeywell control ecosystem. With built-in diagnostics, high-speed logic execution, and integration with the PlantScape and TDC platforms, it delivers reliability, flexibility, and long-term support in industrial environments.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | 621-0071 |

| Module Type | Logic Manager Module |

| Function | Executes discrete and sequential logic operations |

| Communication Interface | Universal Control Network (UCN) |

| Control Strategy Type | Ladder logic, Boolean expressions, sequential control |

| Execution Time | <10 ms for typical logic scans |

| Internal Diagnostics | Yes – error logging, watchdog, and self-test |

| Input Types | Binary inputs (via digital input modules) |

| Output Types | Binary outputs (via digital output modules) |

| Programming Environment | Honeywell Logic Manager configuration tools |

| Power Source | Via backplane supply |

| Power Consumption | Approx. 5.5W |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C (-40°F to 185°F) |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Mounting | DIN rail or Honeywell system backplane |

| Dimensions (W x H x D) | 50 x 130 x 160 mm |

| Weight | 0.52 kg |

| Compliance/Certifications | CE, UL, RoHS, ISA compliant |

| System Compatibility | Honeywell TDC 2000, TDC 3000, PlantScape |

Applications

The 621-0071 Logic Manager Module is purpose-built for executing logic operations in process automation. Its wide adoption across industries underscores its versatility and reliability. Common application areas include:

Power Generation

Turbine interlock logic, breaker control, and emergency shutdown sequences.

Oil & Gas Processing

Logic for safety interlocks, pump control, and flare system coordination.

Petrochemical Plants

Execution of batch sequences, process step logic, and system alarms.

Water and Wastewater

Valve sequencing, pump alternation logic, and tank level interlocks.

Pharmaceutical Manufacturing

Batch control steps, validation interlocks, and compliance sequences.

Pulp and Paper

Boiler logic control, paper machine startup/shutdown procedures.

Key Advantages

Fast and Deterministic Logic Execution

Delivers sub-10 ms logic scan times, critical for high-speed interlocking and control.

Integrated with Honeywell DCS

Seamless operation with TDC 2000/3000 and PlantScape systems via UCN.

Built-in Diagnostics

Monitors logic execution, reports system health, and logs internal faults.

Compact and Durable Design

Industrial-grade module built to withstand demanding plant environments.

Flexible Logic Programming

Supports ladder diagrams, Boolean logic, and complex control sequences.

Reduces Downtime

High availability design with robust error recovery and logic persistence.

Field-Proven Reliability

Long lifecycle and wide deployment in mission-critical control systems worldwide.

Frequently Asked Questions (FAQ)

What is the primary function of the 621-0071 module?

It processes discrete and sequential control logic, often used for interlocks, machine control, and sequencing.

Does it support real-time logic processing?

Yes, it delivers high-speed deterministic logic execution with response times typically under 10 ms.

How is it configured?

Logic is developed using Honeywell’s configuration tools (e.g., Logic Manager or UCN-configurable environments).

Can it be used in redundant configurations?

While redundancy may be supported at a system level, the 621-0071 is typically deployed as a single logic controller per unit operation.

Is the module hot-swappable?

It’s recommended to power down the system or isolate the segment before removing or replacing the module.

What types of signals does it process?

It handles digital (binary) inputs and outputs via separate I/O modules connected through the control system.

What Honeywell systems is it compatible with?

Fully compatible with TDC 2000, TDC 3000, and PlantScape systems.

Does it include error logging?

Yes, onboard diagnostics track execution errors, communication faults, and system status.

What kind of logic can I program into it?

Ladder logic, Boolean expressions, and custom sequential control steps.

How is communication handled with other system elements?

Through the Universal Control Network (UCN), allowing integration with I/O modules and higher-level controllers.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...