Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

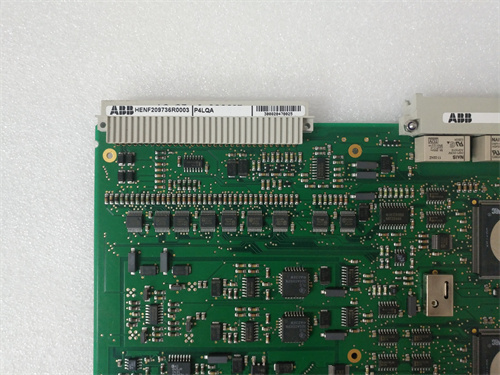

ABB CI615 3BHT300024R1 Bus Coupler

Manufacturer:ABB

Product Number:CI615 3BHT300024R1

Product Type:Bus Coupler

Origin:Sweden

Dimensions:252 x 273 x 40 mm

Weight:1.2kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB CI615 3BHT300024R1 is an industrial bus coupler module designed for use in ABB Freelance and Symphony Plus control systems. As a vital interface component, the CI615 provides communication between the CPU module and distributed I/O modules, ensuring efficient and reliable data transfer in process automation systems. Its rugged construction, protocol compatibility, and compact form make it suitable for a wide range of control architectures across industries.

Key Features

Bridge between CPU and I/O modules in ABB control networks

-

Supports redundant communication to improve system reliability

-

Fully compatible with ABB Freelance and Symphony Plus systems

-

Designed for DIN rail mounting with compact, industrial form

LED indicators for diagnostics and communication status

Robust EMC shielding for industrial environments

-

Plug-and-play setup with minimal configuration requirements

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | CI615 |

| Part Number | 3BHT300024R1 |

| Product Type | Bus Coupler Module |

| System Compatibility | Freelance, Symphony Plus |

| Communication Interface | System Bus / ModuleBus |

| Redundancy | Supported (Redundant System Bus configuration) |

| Power Supply Voltage | 24 V DC |

| Status Indicators | LED indicators for power, communication, and fault |

| Wiring Type | Plug-in terminal blocks |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -25°C to +70°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Cooling Method | Passive convection |

| Dimensions | 252 x 273 x 40 mm |

| Weight | 1.2 kg |

| Mounting | DIN rail or cabinet backplate |

| Certifications | CE, RoHS, IEC 61131-2 compliant |

Industry Applications

The ABB CI615 Bus Coupler is suited for automation applications across several sectors, including:

Power & Utilities – Substation automation, control of auxiliary systems

Oil & Gas – Distributed I/O for pipeline and compressor station automation

Chemical Processing – Process monitoring and distributed field control

Pulp & Paper – Remote machine control and data acquisition

Water & Wastewater – Distributed sensor and actuator communication

Metals & Mining – Motor and drive I/O interfacing across long distances

Product Advantages

Enhanced Reliability – Redundancy support reduces single point of failure

High Interoperability – Seamlessly connects multiple ABB controller families

Ease of Integration – Plug-and-play interface, reducing engineering time

Compact Design – Saves cabinet space and allows for high-density installation

Extended Lifecycle – ABB guarantees long-term availability and support

Diagnostics Friendly – Visual status via LED indicators simplifies troubleshooting

Frequently Asked Questions (FAQ)

What does the CI615 Bus Coupler do?

It acts as a communication bridge between the controller and I/O modules in ABB systems.

Which control systems is CI615 compatible with?

It works with ABB Freelance and Symphony Plus systems.

Does the CI615 support redundancy?

Yes, it supports redundant communication for fault-tolerant setups.

What voltage is required for the CI615 module?

It operates on a 24 V DC power supply.

Can it be hot-swapped during operation?

No, power-down is required before removal or replacement.

How do you mount the CI615?

It is designed for DIN rail or backplate cabinet mounting.

Does the module require programming?

No, it is typically plug-and-play with automatic configuration in ABB systems.

What kind of wiring does it use?

The module uses plug-in terminal blocks for secure and easy wiring.

Are LED indicators available?

Yes, LEDs provide immediate feedback on communication and module status.

Is this module still supported by ABB?

Yes, ABB provides full lifecycle support including spares and documentation.

ABB CI615 3BHT300024R1 Bus Coupler

Manufacturer:ABB

Product Number:CI615 3BHT300024R1

Product Type:Bus Coupler

Origin:Sweden

Dimensions:252 x 273 x 40 mm

Weight:1.2kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB CI615 3BHT300024R1 is an industrial bus coupler module designed for use in ABB Freelance and Symphony Plus control systems. As a vital interface component, the CI615 provides communication between the CPU module and distributed I/O modules, ensuring efficient and reliable data transfer in process automation systems. Its rugged construction, protocol compatibility, and compact form make it suitable for a wide range of control architectures across industries.

Key Features

Bridge between CPU and I/O modules in ABB control networks

-

Supports redundant communication to improve system reliability

-

Fully compatible with ABB Freelance and Symphony Plus systems

-

Designed for DIN rail mounting with compact, industrial form

LED indicators for diagnostics and communication status

Robust EMC shielding for industrial environments

-

Plug-and-play setup with minimal configuration requirements

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | CI615 |

| Part Number | 3BHT300024R1 |

| Product Type | Bus Coupler Module |

| System Compatibility | Freelance, Symphony Plus |

| Communication Interface | System Bus / ModuleBus |

| Redundancy | Supported (Redundant System Bus configuration) |

| Power Supply Voltage | 24 V DC |

| Status Indicators | LED indicators for power, communication, and fault |

| Wiring Type | Plug-in terminal blocks |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -25°C to +70°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Cooling Method | Passive convection |

| Dimensions | 252 x 273 x 40 mm |

| Weight | 1.2 kg |

| Mounting | DIN rail or cabinet backplate |

| Certifications | CE, RoHS, IEC 61131-2 compliant |

Industry Applications

The ABB CI615 Bus Coupler is suited for automation applications across several sectors, including:

Power & Utilities – Substation automation, control of auxiliary systems

Oil & Gas – Distributed I/O for pipeline and compressor station automation

Chemical Processing – Process monitoring and distributed field control

Pulp & Paper – Remote machine control and data acquisition

Water & Wastewater – Distributed sensor and actuator communication

Metals & Mining – Motor and drive I/O interfacing across long distances

Product Advantages

Enhanced Reliability – Redundancy support reduces single point of failure

High Interoperability – Seamlessly connects multiple ABB controller families

Ease of Integration – Plug-and-play interface, reducing engineering time

Compact Design – Saves cabinet space and allows for high-density installation

Extended Lifecycle – ABB guarantees long-term availability and support

Diagnostics Friendly – Visual status via LED indicators simplifies troubleshooting

Frequently Asked Questions (FAQ)

What does the CI615 Bus Coupler do?

It acts as a communication bridge between the controller and I/O modules in ABB systems.

Which control systems is CI615 compatible with?

It works with ABB Freelance and Symphony Plus systems.

Does the CI615 support redundancy?

Yes, it supports redundant communication for fault-tolerant setups.

What voltage is required for the CI615 module?

It operates on a 24 V DC power supply.

Can it be hot-swapped during operation?

No, power-down is required before removal or replacement.

How do you mount the CI615?

It is designed for DIN rail or backplate cabinet mounting.

Does the module require programming?

No, it is typically plug-and-play with automatic configuration in ABB systems.

What kind of wiring does it use?

The module uses plug-in terminal blocks for secure and easy wiring.

Are LED indicators available?

Yes, LEDs provide immediate feedback on communication and module status.

Is this module still supported by ABB?

Yes, ABB provides full lifecycle support including spares and documentation.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...