Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

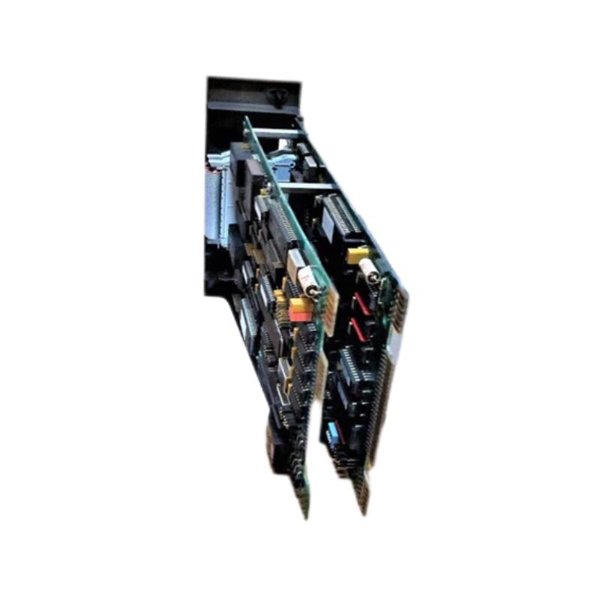

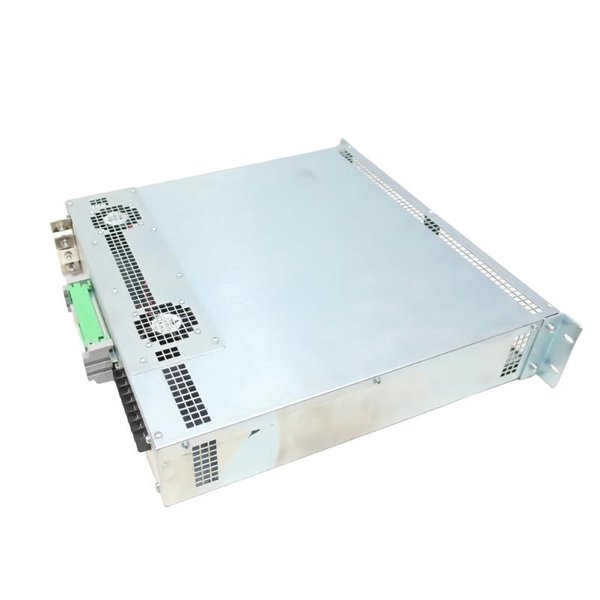

ABB Bailey PHARPSCH100000 MPS III Power Supply Chassis

Manufacturer:ABB Bailey

Product Number:PHARPSCH100000

Product Type:MPS III Power Supply Chassis

Origin:Sweden

Dimensions:540 × 230 × 550 mm

Weight:3.8 kg

Views:25

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB Bailey PHARPSCH100000 is a robust Power Supply Chassis that belongs to the MPS III (Modular Power System) product family. Designed for use in Bailey INFI 90, Net 90, and Symphony DCS systems, the PHARPSCH100000 provides a modular and scalable framework for mounting and powering multiple MPS III power supply modules. It serves as the physical and electrical backbone that connects field power to distributed control processors, I/O modules, and communication interfaces.

This power chassis accommodates hot-swappable, redundant power supply modules, ensuring continuous operation and minimizing downtime in mission-critical industrial environments. It is engineered for high availability, modularity, and system flexibility—making it ideal for control systems that demand uninterrupted power delivery, load balancing, and fault isolation.

Built from industrial-grade materials and conforming to ABB’s stringent manufacturing standards, the PHARPSCH100000 is a trusted backbone in process automation systems that operate around the clock in harsh operating conditions.

Product Specifications

| Parameter | Description |

|---|---|

| Model | PHARPSCH100000 |

| Full Product Name | MPS III Power Supply Chassis |

| Product Type | Power Supply Chassis / Enclosure |

| Series | MPS III |

| Compatible Modules | PHARPSM100000, PHARPSM200000, PHARPSM300000 |

| System Compatibility | ABB Bailey INFI 90, Net 90, Symphony DCS |

| Input Voltage (via Modules) | 120/240 VAC or 24 VDC (via mounted power modules) |

| Output Voltage Distribution | ±5 VDC, +24 VDC, etc. (module-specific) |

| Power Redundancy Support | Yes (dual redundant module slots) |

| Mounting Style | Rack-mount or cabinet panel-mount |

| Slots Available | Typically 2–4 power module bays |

| Backplane Communication | Internal power bus and signal distribution |

| Material | Industrial metal frame, aluminum/steel composite chassis |

| Cooling | Passive ventilation (open-frame) or optional fan cooling |

| Protection Rating | IP20 (when installed in enclosure) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions (W × H × D) | 540 × 230 × 550 mm |

| Weight | 3.8 kg |

| Certifications | CE, UL, RoHS compliant |

Product Applications

The PHARPSCH100000 MPS III Power Supply Chassis is used extensively in critical process automation infrastructures where power reliability is paramount. It serves as the power distribution platform for high-availability systems and is ideal for:

Power Plants – Supplies redundant DC power to turbine control, load shedding modules, and protection relays.

Oil & Gas Refineries – Maintains uninterrupted power to DCS racks during unit startup, shutdown, and process fluctuations.

Chemical & Petrochemical Facilities – Delivers clean, isolated power to analog and digital I/O systems.

Water Treatment Plants – Supports continuous power for pump control logic, level monitoring, and telemetry systems.

Mining Operations – Stabilizes power to underground automation networks, motor control centers, and instrumentation.

Pulp & Paper Mills – Ensures constant voltage supply to distributed control, batching, and paper path systems.

Product Advantages

High Availability Design: Built to support dual redundant power modules for continuous system operation.

Scalable and Modular: Easily integrates additional power modules as system load grows or redundancy is required.

Passive Distribution Backplane: Ensures seamless voltage distribution to all connected modules without external cabling.

Flexible Mounting Options: Suitable for rack-based or panel-mounted industrial control cabinets.

Rugged Construction: Industrial-grade materials and robust design withstand temperature, vibration, and EMI environments.

Lifecycle Extension: Helps extend the service life of ABB INFI 90 and Symphony systems without needing full upgrades.

Minimal Downtime: Hot-swappable module design allows field replacement without shutting down the system.

Global Certification: CE, UL, and RoHS compliance ensures suitability for international deployments.

Field Proven Reliability: In use globally across heavy industry with a long track record of dependable service.

ABB Support Ecosystem: Fully backed by ABB’s lifecycle services including spares, repair, and modernization.

Frequently Asked Questions (FAQ)

What is the primary function of the PHARPSCH100000 chassis?

It provides structural and electrical support for ABB MPS III power supply modules in industrial control systems.

Can I use the chassis with both AC and DC input modules?

Yes. The chassis itself is passive; voltage input depends on the installed power supply modules.

Does the chassis include internal cooling fans?

No, the base unit does not include fans, but optional external cooling can be integrated if required.

Is it possible to mount this chassis in a standard 19-inch rack?

Yes. The unit is compatible with industry-standard rack mounting.

How many power modules can be installed simultaneously?

It supports 2–4 modules, depending on the configuration and redundancy requirements.

Can power modules be replaced while the system is running?

Yes, the hot-swappable feature allows modules to be changed without system shutdown.

What are the benefits of redundancy in this chassis?

Redundant modules ensure continuous power even if one module fails, improving system uptime.

Is the PHARPSCH100000 compatible with other ABB product families?

It is specifically designed for the MPS III family and ABB Bailey control systems.

How do I monitor the health of the installed power modules?

Most modules offer status LEDs or feedback to the control system for health and fault monitoring.

What maintenance is required for the chassis?

Regular checks for dust, terminal tightness, and physical integrity are recommended. No internal active components require servicing.

ABB Bailey PHARPSCH100000 MPS III Power Supply Chassis

Manufacturer:ABB Bailey

Product Number:PHARPSCH100000

Product Type:MPS III Power Supply Chassis

Origin:Sweden

Dimensions:540 × 230 × 550 mm

Weight:3.8 kg

Views:25

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB Bailey PHARPSCH100000 is a robust Power Supply Chassis that belongs to the MPS III (Modular Power System) product family. Designed for use in Bailey INFI 90, Net 90, and Symphony DCS systems, the PHARPSCH100000 provides a modular and scalable framework for mounting and powering multiple MPS III power supply modules. It serves as the physical and electrical backbone that connects field power to distributed control processors, I/O modules, and communication interfaces.

This power chassis accommodates hot-swappable, redundant power supply modules, ensuring continuous operation and minimizing downtime in mission-critical industrial environments. It is engineered for high availability, modularity, and system flexibility—making it ideal for control systems that demand uninterrupted power delivery, load balancing, and fault isolation.

Built from industrial-grade materials and conforming to ABB’s stringent manufacturing standards, the PHARPSCH100000 is a trusted backbone in process automation systems that operate around the clock in harsh operating conditions.

Product Specifications

| Parameter | Description |

|---|---|

| Model | PHARPSCH100000 |

| Full Product Name | MPS III Power Supply Chassis |

| Product Type | Power Supply Chassis / Enclosure |

| Series | MPS III |

| Compatible Modules | PHARPSM100000, PHARPSM200000, PHARPSM300000 |

| System Compatibility | ABB Bailey INFI 90, Net 90, Symphony DCS |

| Input Voltage (via Modules) | 120/240 VAC or 24 VDC (via mounted power modules) |

| Output Voltage Distribution | ±5 VDC, +24 VDC, etc. (module-specific) |

| Power Redundancy Support | Yes (dual redundant module slots) |

| Mounting Style | Rack-mount or cabinet panel-mount |

| Slots Available | Typically 2–4 power module bays |

| Backplane Communication | Internal power bus and signal distribution |

| Material | Industrial metal frame, aluminum/steel composite chassis |

| Cooling | Passive ventilation (open-frame) or optional fan cooling |

| Protection Rating | IP20 (when installed in enclosure) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions (W × H × D) | 540 × 230 × 550 mm |

| Weight | 3.8 kg |

| Certifications | CE, UL, RoHS compliant |

Product Applications

The PHARPSCH100000 MPS III Power Supply Chassis is used extensively in critical process automation infrastructures where power reliability is paramount. It serves as the power distribution platform for high-availability systems and is ideal for:

Power Plants – Supplies redundant DC power to turbine control, load shedding modules, and protection relays.

Oil & Gas Refineries – Maintains uninterrupted power to DCS racks during unit startup, shutdown, and process fluctuations.

Chemical & Petrochemical Facilities – Delivers clean, isolated power to analog and digital I/O systems.

Water Treatment Plants – Supports continuous power for pump control logic, level monitoring, and telemetry systems.

Mining Operations – Stabilizes power to underground automation networks, motor control centers, and instrumentation.

Pulp & Paper Mills – Ensures constant voltage supply to distributed control, batching, and paper path systems.

Product Advantages

High Availability Design: Built to support dual redundant power modules for continuous system operation.

Scalable and Modular: Easily integrates additional power modules as system load grows or redundancy is required.

Passive Distribution Backplane: Ensures seamless voltage distribution to all connected modules without external cabling.

Flexible Mounting Options: Suitable for rack-based or panel-mounted industrial control cabinets.

Rugged Construction: Industrial-grade materials and robust design withstand temperature, vibration, and EMI environments.

Lifecycle Extension: Helps extend the service life of ABB INFI 90 and Symphony systems without needing full upgrades.

Minimal Downtime: Hot-swappable module design allows field replacement without shutting down the system.

Global Certification: CE, UL, and RoHS compliance ensures suitability for international deployments.

Field Proven Reliability: In use globally across heavy industry with a long track record of dependable service.

ABB Support Ecosystem: Fully backed by ABB’s lifecycle services including spares, repair, and modernization.

Frequently Asked Questions (FAQ)

What is the primary function of the PHARPSCH100000 chassis?

It provides structural and electrical support for ABB MPS III power supply modules in industrial control systems.

Can I use the chassis with both AC and DC input modules?

Yes. The chassis itself is passive; voltage input depends on the installed power supply modules.

Does the chassis include internal cooling fans?

No, the base unit does not include fans, but optional external cooling can be integrated if required.

Is it possible to mount this chassis in a standard 19-inch rack?

Yes. The unit is compatible with industry-standard rack mounting.

How many power modules can be installed simultaneously?

It supports 2–4 modules, depending on the configuration and redundancy requirements.

Can power modules be replaced while the system is running?

Yes, the hot-swappable feature allows modules to be changed without system shutdown.

What are the benefits of redundancy in this chassis?

Redundant modules ensure continuous power even if one module fails, improving system uptime.

Is the PHARPSCH100000 compatible with other ABB product families?

It is specifically designed for the MPS III family and ABB Bailey control systems.

How do I monitor the health of the installed power modules?

Most modules offer status LEDs or feedback to the control system for health and fault monitoring.

What maintenance is required for the chassis?

Regular checks for dust, terminal tightness, and physical integrity are recommended. No internal active components require servicing.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...