Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

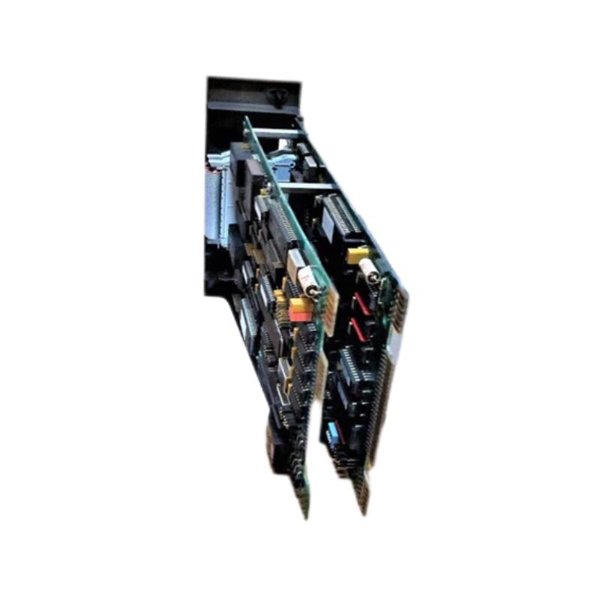

ABB Bailey IMRIO02 Remote I/O Module

Manufacturer:ABB Bailey

Product Number:IMRIO02

Product Type:Remote I/O Module

Origin:Sweden

Dimensions:380 x 120 x 30 mm

Weight:0.386 kg

Views:53

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB Bailey IMRIO02 Remote I/O Module is a robust and highly dependable interface component designed for ABB’s INFI 90 Distributed Control System (DCS). It serves as a communication bridge between remote I/O racks and the main system controller, enabling accurate and real-time data exchange across distributed processing units.

In large-scale industrial operations, control systems often span wide physical areas. The IMRIO02 module allows field devices and sensors to be installed remotely from the central controller without sacrificing response time, signal integrity, or system redundancy. This makes it ideal for applications where scalability and operational reliability are crucial.

The IMRIO02 not only facilitates communication but also provides diagnostic capabilities, ensuring that field-level devices remain integrated with plant operations under all conditions. Its rugged construction, high-speed data processing, and seamless compatibility with Bailey INFI 90 architecture make it an essential component in mission-critical environments.

Product Specifications

| Parameter | Specification |

|---|---|

| Manufacturer | ABB (Bailey Controls) |

| Model Number | IMRIO02 |

| Product Type | Remote I/O Interface Module |

| System Compatibility | INFI 90 Process Control System |

| Communication Protocol | Proprietary INFI-NET |

| Transmission Mode | Asynchronous serial communication with remote I/O racks |

| Supported Modules | Analog/Digital I/O, Control Modules in remote locations |

| Diagnostic Capabilities | Built-in self-checks, error indicators via front-panel LEDs |

| Power Supply Requirement | Supplied via system backplane |

| Mounting Type | Card-mounted in standard INFI 90 chassis |

| LED Indicators | Power status, communication activity, fault diagnostics |

| Operating Temperature Range | 0°C to +60°C (32°F to 140°F) |

| Storage Temperature Range | -40°C to +85°C (-40°F to 185°F) |

| Relative Humidity Range | 5% to 95% non-condensing |

| Cooling Method | Passive convection |

| Certifications | CE, UL, CSA (depending on installation environment) |

| Dimensions (H x W x D) | 380 x 120 x 30 mm |

| Weight | 0.386 kg |

| Redundancy Support | Yes, dual-module redundancy capable |

| Maintenance | Hot-swappable during redundancy operation |

Product Applications

The IMRIO02 is designed to meet the needs of advanced, geographically distributed industrial control environments. Its core applications include:

Power Generation Facilities

Supporting remote monitoring and control of turbine auxiliaries, electrical substations, and balance-of-plant systems.

Oil and Gas Pipelines

Transmitting real-time I/O signals across long distances for pipeline pumps, compressors, and emergency shutdown systems.

Chemical Processing Units

Enabling centralized control with extended field sensing and actuation throughout reactor and separation areas.

Water and Wastewater Systems

Managing remote valve stations, reservoirs, and treatment equipment across distributed geographical zones.

Heavy Industrial Manufacturing

Allowing for modular factory layouts with separate control islands for conveyor systems, robots, and processing lines.

Metals and Mining Operations

Facilitating communication with equipment in rugged, remote mine or smelting plant locations.

Product Advantages

Reliable Remote I/O Expansion

Seamlessly extends the reach of the central control system to remote field devices with minimal latency.

High System Integrity

Supports redundant configurations for uninterrupted data communication and enhanced operational uptime.

Diagnostic-Friendly

Equipped with onboard indicators and built-in error checking to minimize maintenance time and fault isolation effort.

Compact and Modular

Its small footprint enables easy deployment even in space-limited chassis configurations.

Field-Proven Durability

Built to withstand industrial temperature and humidity ranges for long-term, stable performance.

Plug-and-Play Integration

Designed for direct compatibility with INFI 90 architecture, simplifying system expansion or retrofit projects.

Passive Cooling

Eliminates the need for fans, reducing noise and points of failure while saving energy.

Hot-Swappable Functionality

Allows replacement in redundant systems without interrupting ongoing operations.

FAQ

What is the primary function of the IMRIO02?

It serves as a remote I/O communication module, linking distant I/O modules to the main control system.

Which control systems support IMRIO02?

The module is specifically designed for ABB Bailey INFI 90 DCS platforms.

Can the IMRIO02 be used in redundant configurations?

Yes, it supports dual-module redundancy for mission-critical applications.

Does this module support diagnostics?

Yes, it includes LED indicators and built-in self-testing capabilities for quick troubleshooting.

What kind of I/O can be connected remotely?

Both digital and analog I/O modules as well as control modules are supported.

Is the IMRIO02 hot-swappable?

Yes, in redundant systems it can be replaced without shutting down operations.

What is the maximum distance it can cover?

It depends on the cabling and system configuration but generally supports long-distance communication.

Does the module require active cooling?

No, it operates efficiently through passive convection cooling.

What type of communication does it use?

It utilizes asynchronous serial communication via INFI-NET.

What industries most commonly use this module?

Power, oil and gas, chemicals, water treatment, and heavy manufacturing sectors.

ABB Bailey IMRIO02 Remote I/O Module

Manufacturer:ABB Bailey

Product Number:IMRIO02

Product Type:Remote I/O Module

Origin:Sweden

Dimensions:380 x 120 x 30 mm

Weight:0.386 kg

Views:53

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB Bailey IMRIO02 Remote I/O Module is a robust and highly dependable interface component designed for ABB’s INFI 90 Distributed Control System (DCS). It serves as a communication bridge between remote I/O racks and the main system controller, enabling accurate and real-time data exchange across distributed processing units.

In large-scale industrial operations, control systems often span wide physical areas. The IMRIO02 module allows field devices and sensors to be installed remotely from the central controller without sacrificing response time, signal integrity, or system redundancy. This makes it ideal for applications where scalability and operational reliability are crucial.

The IMRIO02 not only facilitates communication but also provides diagnostic capabilities, ensuring that field-level devices remain integrated with plant operations under all conditions. Its rugged construction, high-speed data processing, and seamless compatibility with Bailey INFI 90 architecture make it an essential component in mission-critical environments.

Product Specifications

| Parameter | Specification |

|---|---|

| Manufacturer | ABB (Bailey Controls) |

| Model Number | IMRIO02 |

| Product Type | Remote I/O Interface Module |

| System Compatibility | INFI 90 Process Control System |

| Communication Protocol | Proprietary INFI-NET |

| Transmission Mode | Asynchronous serial communication with remote I/O racks |

| Supported Modules | Analog/Digital I/O, Control Modules in remote locations |

| Diagnostic Capabilities | Built-in self-checks, error indicators via front-panel LEDs |

| Power Supply Requirement | Supplied via system backplane |

| Mounting Type | Card-mounted in standard INFI 90 chassis |

| LED Indicators | Power status, communication activity, fault diagnostics |

| Operating Temperature Range | 0°C to +60°C (32°F to 140°F) |

| Storage Temperature Range | -40°C to +85°C (-40°F to 185°F) |

| Relative Humidity Range | 5% to 95% non-condensing |

| Cooling Method | Passive convection |

| Certifications | CE, UL, CSA (depending on installation environment) |

| Dimensions (H x W x D) | 380 x 120 x 30 mm |

| Weight | 0.386 kg |

| Redundancy Support | Yes, dual-module redundancy capable |

| Maintenance | Hot-swappable during redundancy operation |

Product Applications

The IMRIO02 is designed to meet the needs of advanced, geographically distributed industrial control environments. Its core applications include:

Power Generation Facilities

Supporting remote monitoring and control of turbine auxiliaries, electrical substations, and balance-of-plant systems.

Oil and Gas Pipelines

Transmitting real-time I/O signals across long distances for pipeline pumps, compressors, and emergency shutdown systems.

Chemical Processing Units

Enabling centralized control with extended field sensing and actuation throughout reactor and separation areas.

Water and Wastewater Systems

Managing remote valve stations, reservoirs, and treatment equipment across distributed geographical zones.

Heavy Industrial Manufacturing

Allowing for modular factory layouts with separate control islands for conveyor systems, robots, and processing lines.

Metals and Mining Operations

Facilitating communication with equipment in rugged, remote mine or smelting plant locations.

Product Advantages

Reliable Remote I/O Expansion

Seamlessly extends the reach of the central control system to remote field devices with minimal latency.

High System Integrity

Supports redundant configurations for uninterrupted data communication and enhanced operational uptime.

Diagnostic-Friendly

Equipped with onboard indicators and built-in error checking to minimize maintenance time and fault isolation effort.

Compact and Modular

Its small footprint enables easy deployment even in space-limited chassis configurations.

Field-Proven Durability

Built to withstand industrial temperature and humidity ranges for long-term, stable performance.

Plug-and-Play Integration

Designed for direct compatibility with INFI 90 architecture, simplifying system expansion or retrofit projects.

Passive Cooling

Eliminates the need for fans, reducing noise and points of failure while saving energy.

Hot-Swappable Functionality

Allows replacement in redundant systems without interrupting ongoing operations.

FAQ

What is the primary function of the IMRIO02?

It serves as a remote I/O communication module, linking distant I/O modules to the main control system.

Which control systems support IMRIO02?

The module is specifically designed for ABB Bailey INFI 90 DCS platforms.

Can the IMRIO02 be used in redundant configurations?

Yes, it supports dual-module redundancy for mission-critical applications.

Does this module support diagnostics?

Yes, it includes LED indicators and built-in self-testing capabilities for quick troubleshooting.

What kind of I/O can be connected remotely?

Both digital and analog I/O modules as well as control modules are supported.

Is the IMRIO02 hot-swappable?

Yes, in redundant systems it can be replaced without shutting down operations.

What is the maximum distance it can cover?

It depends on the cabling and system configuration but generally supports long-distance communication.

Does the module require active cooling?

No, it operates efficiently through passive convection cooling.

What type of communication does it use?

It utilizes asynchronous serial communication via INFI-NET.

What industries most commonly use this module?

Power, oil and gas, chemicals, water treatment, and heavy manufacturing sectors.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...