Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

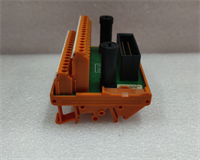

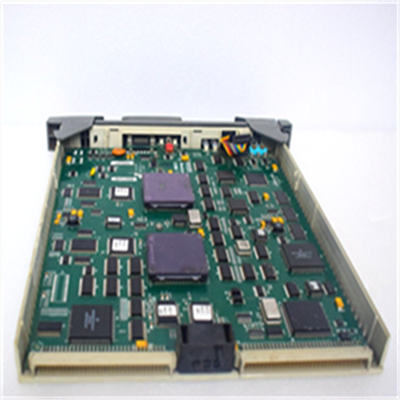

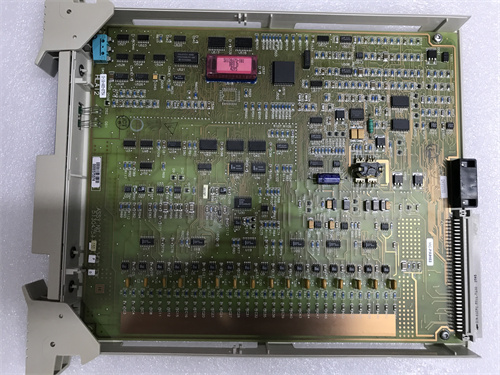

Honeywell FC-SAL-1620M Safety Management System Module

Manufacturer:Honeywell

Product Number:FC-SAL-1620M

Product Type:Safety Management System Module

Origin:USA

Dimensions:130 × 50 × 120 mm

Weight:0.3 kg

Views:77

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell FC-SAL-1620M Safety Management System Module is a critical component of Honeywell’s Safety Manager platform, a SIL 3 TÜV-certified safety system that supports both safety and pr

ocess control functions in demanding industrial environments. As part of the Fail-Safe Controller (FSC) architecture, the FC-SAL-1620M is specifically designed to ensure the integrity, reliability, and availability of safety-critical functions across various industrial sectors, including oil and gas, petrochemical, power generation, and pharmaceuticals.

This module provides high-integrity I/O interfacing, acting as a safety input/output module that can be configured and diagnosed through Honeywell’s Safety Builder or Experion PKS engineering tools. It is engineered to support applications that require stringent functional safety, real-time diagnostics, redundancy, and continuous operation under harsh environmental conditions.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | FC-SAL-1620M |

| System Compatibility | Safety Manager, Experion PKS, FSC System |

| Functionality | Safety Analog Input/Output Module (configurable) |

| Channels | 16 Channels, configurable for analog input or output |

| Signal Type | 4–20 mA current loop, HART capable (optional) |

| Resolution | 16-bit conversion |

| Input Accuracy | ±0.1% of span |

| Output Accuracy | ±0.1% of span |

| Diagnostics | Channel-level diagnostics, loop monitoring, power loss detection |

| Redundancy Support | Yes – module level and power input redundancy |

| Hot Swap Support | Yes – with no process interruption |

| Communication Protocol | Proprietary SafeNet / FTE (via Safety Manager backplane) |

| Configuration Tools | Safety Builder, Safety Designer, Experion Control Builder |

| Status Indicators | Per-channel and module health LEDs |

| Power Supply Voltage | Supplied via I/O chassis backplane |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% RH, non-condensing |

| Shock and Vibration Resistance | Compliant with IEC 60068-2-6 and 2-27 |

| Certifications | TÜV (SIL3), CE, ATEX, GOST, IECEx, CSA |

| Mounting Type | DIN rail or rack mount (in standard Safety Manager chassis) |

| Dimensions (H × W × D) | 130 × 50 × 120 mm |

| Weight | 0.3 kg |

Product Applications

The FC-SAL-1620M is deployed in applications where functional safety and continuous availability are essential. The module plays a central role in ensuring safe process shutdown, interlocks, and emergency controls.

Emergency Shutdown Systems (ESD): Used in upstream and downstream oil & gas plants to ensure safe plant isolation during critical events.

Burner Management Systems (BMS): Provides real-time safety monitoring and control of combustion systems in power plants and refineries.

Fire & Gas Detection: Integrates with detectors and gas analyzers to trigger safe responses during fire or hazardous gas leaks.

Boiler Safety Systems: Ensures fail-safe operation and shutdown of high-pressure boilers in process industries.

Overpressure Protection Systems: Works alongside pressure transmitters to initiate relief or depressurization procedures.

HIPPS (High Integrity Pressure Protection Systems): Ensures compliance with safety integrity requirements for pipeline protection.

Product Advantages

SIL 3 Certified: Complies with IEC 61508 standards, offering maximum safety assurance for high-risk industries.

Dual Redundancy Capabilities: Supports redundant power, module, and I/O configurations for uninterrupted operation.

Hot Swappable Design: Enables safe module replacement without process downtime.

Advanced Diagnostics: Real-time fault detection at the channel and module level enhances preventive maintenance.

Modular Scalability: Easily integrates into existing Safety Manager architectures for flexible expansion.

Universal Channel Configuration: Reduces inventory and engineering time by supporting multiple I/O signal types.

Secure Integration with Experion PKS: Ensures full compatibility with Honeywell’s flagship control platforms.

Built-in Loop Monitoring: Offers continuous feedback on loop integrity to prevent hidden faults.

FAQ

Can each channel of the FC-SAL-1620M be configured as input or output?

Yes, each of the 16 channels is software configurable for either analog input or output function.

Does the module support HART communication?

HART support is optional and requires proper configuration via Safety Builder.

Is the FC-SAL-1620M module hot-swappable?

Yes, it supports hot-swapping within a redundant configuration to avoid downtime.

Can the module be used in a SIL 3 loop?

Absolutely, the FC-SAL-1620M is TÜV certified for use in SIL 3 safety instrumented functions.

What happens if one channel fails?

The module performs continuous diagnostics and will flag the exact faulty channel, enabling selective deactivation without affecting others.

Is redundancy supported at the module level?

Yes, redundancy is supported for both the module and power input, depending on the system configuration.

What is the input signal resolution?

The module offers a 16-bit resolution for accurate analog signal conversion.

Can this module be integrated with standard PLCs?

Direct integration is designed for Honeywell Safety Manager, though third-party interfacing is possible via protocol converters.

What engineering tools are used for configuration?

Configuration is performed through Safety Builder or integrated with Experion’s Control Builder tools.

How does the module handle field power loss?

It has built-in loop supervision and diagnostics to detect and report power loss on individual channels.

Honeywell FC-SAL-1620M Safety Management System Module

Manufacturer:Honeywell

Product Number:FC-SAL-1620M

Product Type:Safety Management System Module

Origin:USA

Dimensions:130 × 50 × 120 mm

Weight:0.3 kg

Views:77

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell FC-SAL-1620M Safety Management System Module is a critical component of Honeywell’s Safety Manager platform, a SIL 3 TÜV-certified safety system that supports both safety and pr

ocess control functions in demanding industrial environments. As part of the Fail-Safe Controller (FSC) architecture, the FC-SAL-1620M is specifically designed to ensure the integrity, reliability, and availability of safety-critical functions across various industrial sectors, including oil and gas, petrochemical, power generation, and pharmaceuticals.

This module provides high-integrity I/O interfacing, acting as a safety input/output module that can be configured and diagnosed through Honeywell’s Safety Builder or Experion PKS engineering tools. It is engineered to support applications that require stringent functional safety, real-time diagnostics, redundancy, and continuous operation under harsh environmental conditions.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | FC-SAL-1620M |

| System Compatibility | Safety Manager, Experion PKS, FSC System |

| Functionality | Safety Analog Input/Output Module (configurable) |

| Channels | 16 Channels, configurable for analog input or output |

| Signal Type | 4–20 mA current loop, HART capable (optional) |

| Resolution | 16-bit conversion |

| Input Accuracy | ±0.1% of span |

| Output Accuracy | ±0.1% of span |

| Diagnostics | Channel-level diagnostics, loop monitoring, power loss detection |

| Redundancy Support | Yes – module level and power input redundancy |

| Hot Swap Support | Yes – with no process interruption |

| Communication Protocol | Proprietary SafeNet / FTE (via Safety Manager backplane) |

| Configuration Tools | Safety Builder, Safety Designer, Experion Control Builder |

| Status Indicators | Per-channel and module health LEDs |

| Power Supply Voltage | Supplied via I/O chassis backplane |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% RH, non-condensing |

| Shock and Vibration Resistance | Compliant with IEC 60068-2-6 and 2-27 |

| Certifications | TÜV (SIL3), CE, ATEX, GOST, IECEx, CSA |

| Mounting Type | DIN rail or rack mount (in standard Safety Manager chassis) |

| Dimensions (H × W × D) | 130 × 50 × 120 mm |

| Weight | 0.3 kg |

Product Applications

The FC-SAL-1620M is deployed in applications where functional safety and continuous availability are essential. The module plays a central role in ensuring safe process shutdown, interlocks, and emergency controls.

Emergency Shutdown Systems (ESD): Used in upstream and downstream oil & gas plants to ensure safe plant isolation during critical events.

Burner Management Systems (BMS): Provides real-time safety monitoring and control of combustion systems in power plants and refineries.

Fire & Gas Detection: Integrates with detectors and gas analyzers to trigger safe responses during fire or hazardous gas leaks.

Boiler Safety Systems: Ensures fail-safe operation and shutdown of high-pressure boilers in process industries.

Overpressure Protection Systems: Works alongside pressure transmitters to initiate relief or depressurization procedures.

HIPPS (High Integrity Pressure Protection Systems): Ensures compliance with safety integrity requirements for pipeline protection.

Product Advantages

SIL 3 Certified: Complies with IEC 61508 standards, offering maximum safety assurance for high-risk industries.

Dual Redundancy Capabilities: Supports redundant power, module, and I/O configurations for uninterrupted operation.

Hot Swappable Design: Enables safe module replacement without process downtime.

Advanced Diagnostics: Real-time fault detection at the channel and module level enhances preventive maintenance.

Modular Scalability: Easily integrates into existing Safety Manager architectures for flexible expansion.

Universal Channel Configuration: Reduces inventory and engineering time by supporting multiple I/O signal types.

Secure Integration with Experion PKS: Ensures full compatibility with Honeywell’s flagship control platforms.

Built-in Loop Monitoring: Offers continuous feedback on loop integrity to prevent hidden faults.

FAQ

Can each channel of the FC-SAL-1620M be configured as input or output?

Yes, each of the 16 channels is software configurable for either analog input or output function.

Does the module support HART communication?

HART support is optional and requires proper configuration via Safety Builder.

Is the FC-SAL-1620M module hot-swappable?

Yes, it supports hot-swapping within a redundant configuration to avoid downtime.

Can the module be used in a SIL 3 loop?

Absolutely, the FC-SAL-1620M is TÜV certified for use in SIL 3 safety instrumented functions.

What happens if one channel fails?

The module performs continuous diagnostics and will flag the exact faulty channel, enabling selective deactivation without affecting others.

Is redundancy supported at the module level?

Yes, redundancy is supported for both the module and power input, depending on the system configuration.

What is the input signal resolution?

The module offers a 16-bit resolution for accurate analog signal conversion.

Can this module be integrated with standard PLCs?

Direct integration is designed for Honeywell Safety Manager, though third-party interfacing is possible via protocol converters.

What engineering tools are used for configuration?

Configuration is performed through Safety Builder or integrated with Experion’s Control Builder tools.

How does the module handle field power loss?

It has built-in loop supervision and diagnostics to detect and report power loss on individual channels.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...