Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

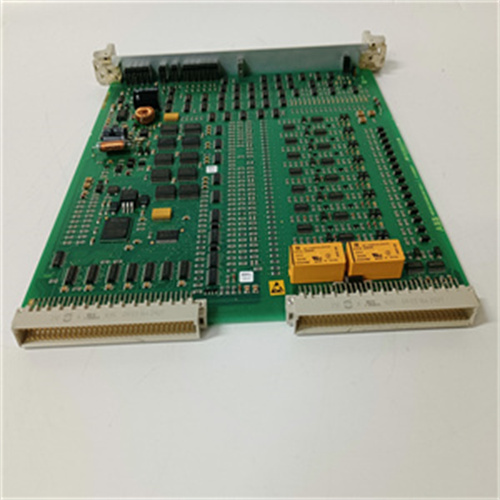

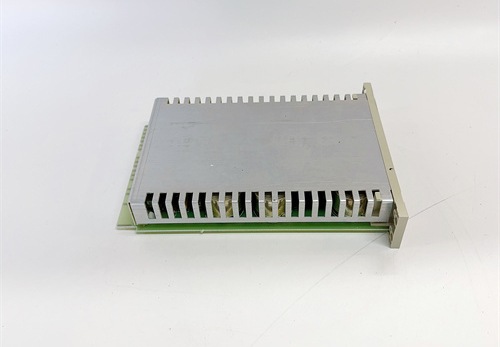

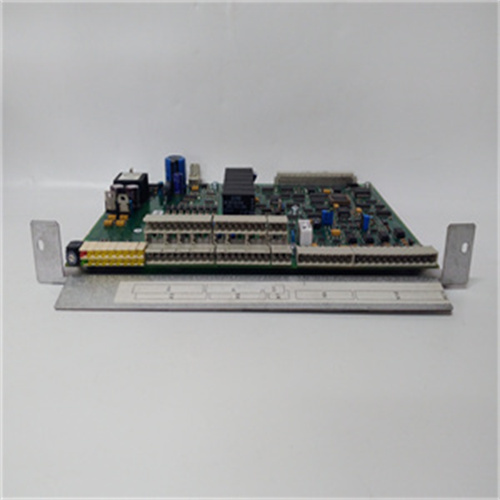

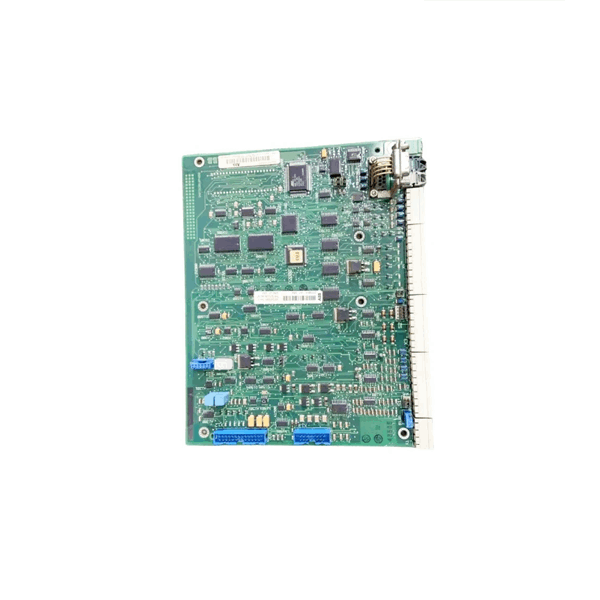

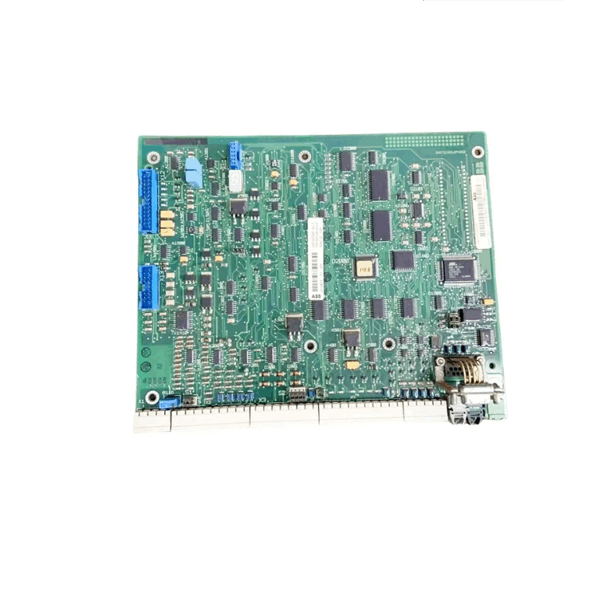

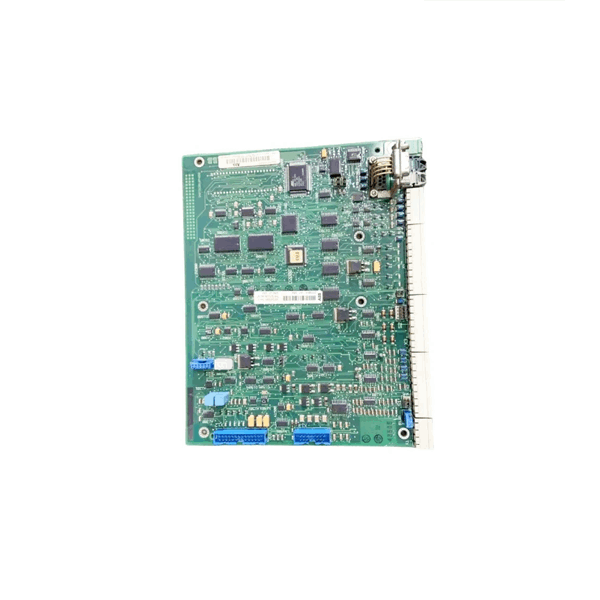

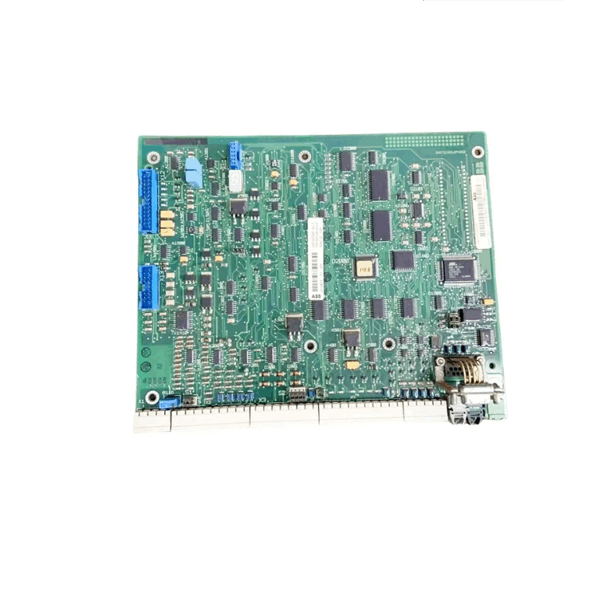

ABB SDCS-CON-3A-COAT 3ADT312000R1 Motherboard

Manufacturer:ABB

Product Number:SDCS-CON-3A-COAT 3ADT312000R1

Condition:Motherboard

Origin:Sweden

Dimensions:120 × 90 × 45 mm

Weight:0.5 kg

Views:45

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB SDCS-CON-3A-COAT (part number 3ADT312000R1) is a coated control board module designed for use in ABB’s DCS (Direct Current Drive System) series, particularly compatible with the DCS500 and DCS600 family of drives. Engineered for robust performance in industrial environments, this module facilitates the management of control and communication functions within the drive system. The conformal coating offers additional protection against moisture, dust, and corrosive agents, making it ideal for harsh operating conditions.

This control board acts as the central interface between user commands, drive logic, and feedback systems, ensuring efficient and reliable DC motor operation.

Product Features and Advantages

Conformal Coated Design

The “COAT” version provides enhanced protection from humidity, dust, and industrial contaminants, extending lifespan in aggressive environments.

Optimized for ABB DCS Drives

Fully compatible with DCS500 and DCS600 series, ensuring seamless integration without additional configuration.

Reliable Signal Processing

Ensures precise and stable control of motor speed, current, and torque through advanced digital signal processing.

Improved System Diagnostics

Integrated fault diagnostics and status LEDs allow quicker troubleshooting and maintenance.

Long Service Life

Built using high-quality industrial-grade components designed for long operational lifespans and minimal downtime.

Compact and Replaceable

Designed for easy installation and replacement, minimizing system downtime during maintenance or upgrades.

Technical Specifications

| Parameter | Description |

|---|---|

| Product Name | SDCS-CON-3A-COAT |

| Part Number | 3ADT312000R1 |

| Product Type | Control Board Module |

| Compatible Series | ABB DCS500 / DCS600 DC Drive Systems |

| Protective Coating | Yes (Conformal Coated) |

| Operating Voltage | Supplied internally by drive system |

| Storage Temperature Range | -25°C to +70°C |

| Operating Temperature Range | 0°C to +55°C |

| Humidity Tolerance | 5% to 95% non-condensing |

| Mounting Type | PCB Mount (Modular Slot-In) |

| Communication Interfaces | Internal ABB backplane bus |

| Dimensions (L x W x H) | 120 × 90 × 45 mm |

| Weight | 0.5 kg |

| Certification | CE, RoHS compliant |

Product Applications

The ABB SDCS-CON-3A-COAT module is used across various industries where DC drive systems are employed, including:

-

Steel and Metal Processing Plants

-

Paper and Pulp Mills

-

Cement Manufacturing Facilities

-

Mining and Excavation Equipment

-

Marine Propulsion Systems

-

Test Benches for Industrial Motors

-

Cranes and Hoists requiring accurate speed control

Its robust performance under tough industrial conditions makes it especially suitable for applications with variable temperature and high humidity levels.

Compatible/Supporting Models

The SDCS-CON-3A-COAT is typically paired with or used in conjunction with:

-

ABB DCS500 and DCS600 Power Modules

-

SDCS-IOE-2 Input/Output Extension Board

-

SDCS-POW-4 Power Supply Module

-

SDCS-UPS-1 UPS Buffer Board

-

SDCS-PIN-3 Encoder Interface Board

-

SDCS-FEX-2 Fiber Optic Communication Module

Installation Instructions

Ensure Drive Power is Disconnected

Always isolate the drive system from power sources before handling internal modules.

Use Proper ESD Protection

Static discharge can damage sensitive circuits; use wrist straps or antistatic mats.

Insert Module into Correct Slot

Align the SDCS-CON-3A-COAT with the designated slot on the DCS controller baseboard and insert firmly.

Secure Connections

Check and secure all backplane and connector interfaces.

Power Up and Test

After installation, power up the system and verify functionality through diagnostics.

Update Firmware or Parameters (if needed)

Use ABB DriveWindow software or operator panel to verify correct configuration.

ABB SDCS-CON-3A-COAT 3ADT312000R1 Motherboard

Manufacturer:ABB

Product Number:SDCS-CON-3A-COAT 3ADT312000R1

Condition:Motherboard

Origin:Sweden

Dimensions:120 × 90 × 45 mm

Weight:0.5 kg

Views:45

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB SDCS-CON-3A-COAT (part number 3ADT312000R1) is a coated control board module designed for use in ABB’s DCS (Direct Current Drive System) series, particularly compatible with the DCS500 and DCS600 family of drives. Engineered for robust performance in industrial environments, this module facilitates the management of control and communication functions within the drive system. The conformal coating offers additional protection against moisture, dust, and corrosive agents, making it ideal for harsh operating conditions.

This control board acts as the central interface between user commands, drive logic, and feedback systems, ensuring efficient and reliable DC motor operation.

Product Features and Advantages

Conformal Coated Design

The “COAT” version provides enhanced protection from humidity, dust, and industrial contaminants, extending lifespan in aggressive environments.

Optimized for ABB DCS Drives

Fully compatible with DCS500 and DCS600 series, ensuring seamless integration without additional configuration.

Reliable Signal Processing

Ensures precise and stable control of motor speed, current, and torque through advanced digital signal processing.

Improved System Diagnostics

Integrated fault diagnostics and status LEDs allow quicker troubleshooting and maintenance.

Long Service Life

Built using high-quality industrial-grade components designed for long operational lifespans and minimal downtime.

Compact and Replaceable

Designed for easy installation and replacement, minimizing system downtime during maintenance or upgrades.

Technical Specifications

| Parameter | Description |

|---|---|

| Product Name | SDCS-CON-3A-COAT |

| Part Number | 3ADT312000R1 |

| Product Type | Control Board Module |

| Compatible Series | ABB DCS500 / DCS600 DC Drive Systems |

| Protective Coating | Yes (Conformal Coated) |

| Operating Voltage | Supplied internally by drive system |

| Storage Temperature Range | -25°C to +70°C |

| Operating Temperature Range | 0°C to +55°C |

| Humidity Tolerance | 5% to 95% non-condensing |

| Mounting Type | PCB Mount (Modular Slot-In) |

| Communication Interfaces | Internal ABB backplane bus |

| Dimensions (L x W x H) | 120 × 90 × 45 mm |

| Weight | 0.5 kg |

| Certification | CE, RoHS compliant |

Product Applications

The ABB SDCS-CON-3A-COAT module is used across various industries where DC drive systems are employed, including:

-

Steel and Metal Processing Plants

-

Paper and Pulp Mills

-

Cement Manufacturing Facilities

-

Mining and Excavation Equipment

-

Marine Propulsion Systems

-

Test Benches for Industrial Motors

-

Cranes and Hoists requiring accurate speed control

Its robust performance under tough industrial conditions makes it especially suitable for applications with variable temperature and high humidity levels.

Compatible/Supporting Models

The SDCS-CON-3A-COAT is typically paired with or used in conjunction with:

-

ABB DCS500 and DCS600 Power Modules

-

SDCS-IOE-2 Input/Output Extension Board

-

SDCS-POW-4 Power Supply Module

-

SDCS-UPS-1 UPS Buffer Board

-

SDCS-PIN-3 Encoder Interface Board

-

SDCS-FEX-2 Fiber Optic Communication Module

Installation Instructions

Ensure Drive Power is Disconnected

Always isolate the drive system from power sources before handling internal modules.

Use Proper ESD Protection

Static discharge can damage sensitive circuits; use wrist straps or antistatic mats.

Insert Module into Correct Slot

Align the SDCS-CON-3A-COAT with the designated slot on the DCS controller baseboard and insert firmly.

Secure Connections

Check and secure all backplane and connector interfaces.

Power Up and Test

After installation, power up the system and verify functionality through diagnostics.

Update Firmware or Parameters (if needed)

Use ABB DriveWindow software or operator panel to verify correct configuration.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...