Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

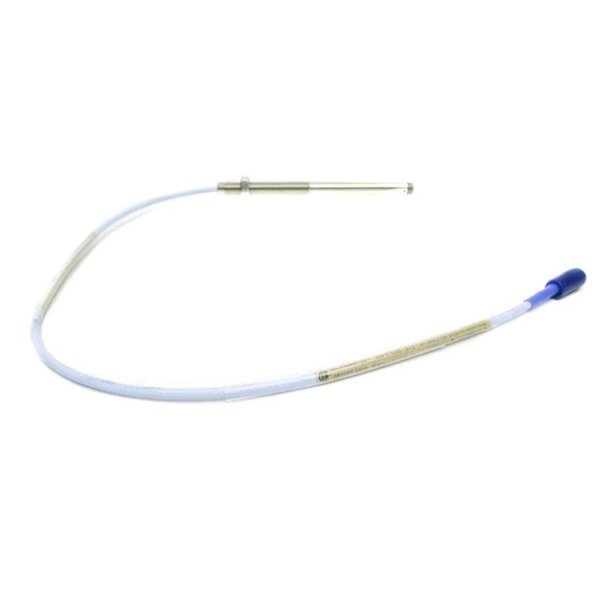

Bently Nevada 330101-23-41-10-02-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330101-23-41-10-02-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1.0 meter

Weight:0.323 kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300 XL 8 mm Proximity Probe is a high-precision sensor for measuring shaft vibration and position in critical rotating machinery. It is designed for fluid-film bearing machines, delivering accurate static (position) and dynamic (vibration) measurements. The probe is part of the 3300 XL transducer system, providing API 670-compliant performance with superior linearity, rugged construction, and full interchangeability of components.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | 330101-23-41-10-02-05 |

| Probe Diameter | 8 mm |

| Probe Material | Stainless Steel (AISI 303/304) |

| Tip Material | PPS (Polyphenylene Sulfide) |

| Cable Length (Total) | 1.0 meter (3.3 ft) |

| Weight | 0.323 kg |

| Linear Range | 2.0 mm (80 mils) |

| Frequency Response | 0–10 kHz (+0, -3 dB) |

| Temperature Range | -52°C to +177°C (probe), -52°C to +100°C (sensor) |

| Minimum Shaft Diameter | 50.8 mm (recommended ≥76.2 mm) |

| Output Scale Factor | 200 mV/mil ±5% |

| Thread Size | 3/8-24 UNF |

| Connector Type | Miniature coaxial ClickLoc |

| Compliance | API 670, CE, RoHS, FCC, SIL2/SIL3 capable |

Applications

-

Vibration and position monitoring of fluid-film bearing turbines and compressors

-

Keyphasor reference and overspeed protection

-

High-temperature and high-density installations

-

Backward-compatible retrofits in existing 3300 series systems

Advantages

-

Fully API 670 compliant

-

Rugged design with high pull strength and superior sealing

-

Interchangeable components reduce calibration effort

-

Excellent RFI/EMI immunity and simplified wiring

-

Extended temperature range options available

FAQs

Q1: What is the primary use of this probe?

A1: It is used for measuring vibration and position in rotating machinery with fluid-film bearings.

Q2: Is it compatible with older 3300 series components?

A2: Yes, it is electrically and mechanically interchangeable with non-XL 3300 series 5 mm and 8 mm components.

Q3: Does it meet API 670 standards?

A3: Yes, it fully complies with API 670 mechanical and performance standards.

Q4: Can it operate in high-temperature environments?

A4: Standard probes operate up to +177°C; extended temperature versions are available for higher limits.

Q5: What is the recommended shaft diameter?

A5: Minimum recommended shaft diameter is 76.2 mm (3 inches) for optimal performance.

Q6: Is calibration required when replacing components?

A6: No, components are fully interchangeable without the need for recalibration.

Q7: What sealing mechanism does the probe use?

A7: It uses a Viton® O-ring seal for reliable differential pressure sealing.

Q8: Does the probe require special tools for installation?

A8: No, the ClickLoc connectors and SpringLoc terminals allow tool-free installation.

Q9: How resistant is it to electromagnetic interference?

A9: It is highly immune to RFI/EMI and meets CE standards.

Q10: What is the linear measurement range of the probe?

A10: The linear range is 2.0 mm (80 mils), starting from approximately 0.25 mm from the target.

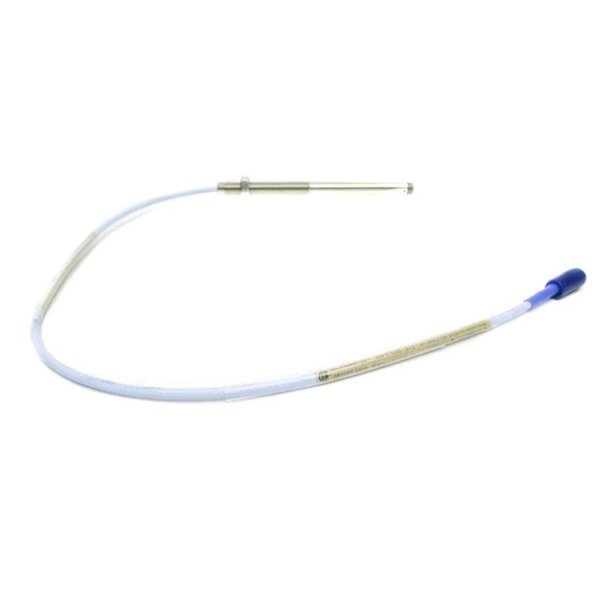

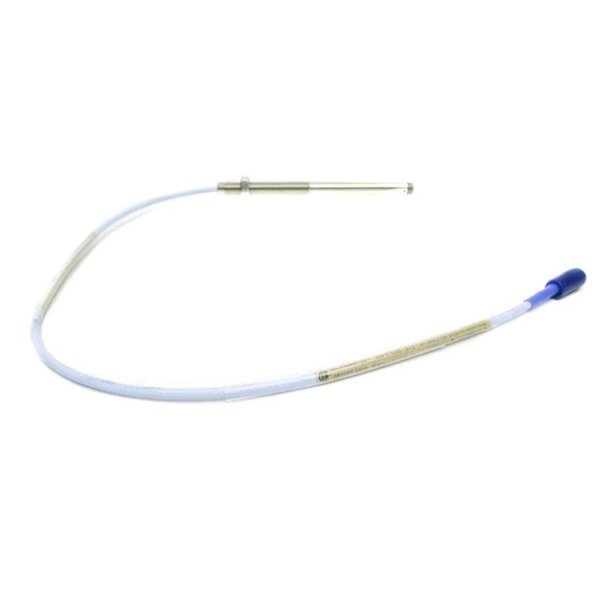

Bently Nevada 330101-23-41-10-02-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330101-23-41-10-02-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1.0 meter

Weight:0.323 kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300 XL 8 mm Proximity Probe is a high-precision sensor for measuring shaft vibration and position in critical rotating machinery. It is designed for fluid-film bearing machines, delivering accurate static (position) and dynamic (vibration) measurements. The probe is part of the 3300 XL transducer system, providing API 670-compliant performance with superior linearity, rugged construction, and full interchangeability of components.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | 330101-23-41-10-02-05 |

| Probe Diameter | 8 mm |

| Probe Material | Stainless Steel (AISI 303/304) |

| Tip Material | PPS (Polyphenylene Sulfide) |

| Cable Length (Total) | 1.0 meter (3.3 ft) |

| Weight | 0.323 kg |

| Linear Range | 2.0 mm (80 mils) |

| Frequency Response | 0–10 kHz (+0, -3 dB) |

| Temperature Range | -52°C to +177°C (probe), -52°C to +100°C (sensor) |

| Minimum Shaft Diameter | 50.8 mm (recommended ≥76.2 mm) |

| Output Scale Factor | 200 mV/mil ±5% |

| Thread Size | 3/8-24 UNF |

| Connector Type | Miniature coaxial ClickLoc |

| Compliance | API 670, CE, RoHS, FCC, SIL2/SIL3 capable |

Applications

-

Vibration and position monitoring of fluid-film bearing turbines and compressors

-

Keyphasor reference and overspeed protection

-

High-temperature and high-density installations

-

Backward-compatible retrofits in existing 3300 series systems

Advantages

-

Fully API 670 compliant

-

Rugged design with high pull strength and superior sealing

-

Interchangeable components reduce calibration effort

-

Excellent RFI/EMI immunity and simplified wiring

-

Extended temperature range options available

FAQs

Q1: What is the primary use of this probe?

A1: It is used for measuring vibration and position in rotating machinery with fluid-film bearings.

Q2: Is it compatible with older 3300 series components?

A2: Yes, it is electrically and mechanically interchangeable with non-XL 3300 series 5 mm and 8 mm components.

Q3: Does it meet API 670 standards?

A3: Yes, it fully complies with API 670 mechanical and performance standards.

Q4: Can it operate in high-temperature environments?

A4: Standard probes operate up to +177°C; extended temperature versions are available for higher limits.

Q5: What is the recommended shaft diameter?

A5: Minimum recommended shaft diameter is 76.2 mm (3 inches) for optimal performance.

Q6: Is calibration required when replacing components?

A6: No, components are fully interchangeable without the need for recalibration.

Q7: What sealing mechanism does the probe use?

A7: It uses a Viton® O-ring seal for reliable differential pressure sealing.

Q8: Does the probe require special tools for installation?

A8: No, the ClickLoc connectors and SpringLoc terminals allow tool-free installation.

Q9: How resistant is it to electromagnetic interference?

A9: It is highly immune to RFI/EMI and meets CE standards.

Q10: What is the linear measurement range of the probe?

A10: The linear range is 2.0 mm (80 mils), starting from approximately 0.25 mm from the target.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...