Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

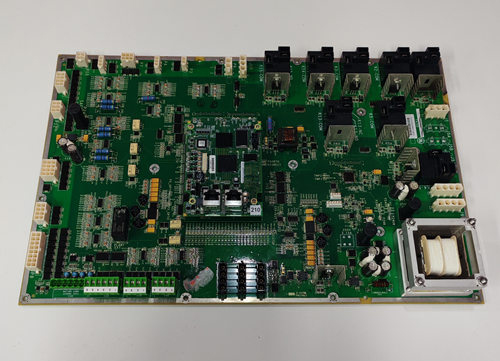

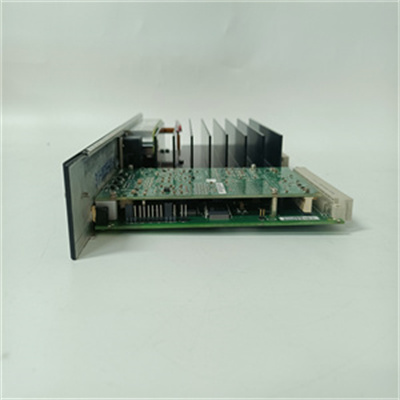

General Electric IS200WEORG1A Wind Turbine Mainboard

Manufacturer:GE

Product Number:IS200WEORG1A

Product Type:Wind Turbine Mainboard

Origin:USA

Dimensions:178 x 51 x 305 mm

Weight:0.5 kg

Views:40

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200WEORG1A is a key component of wind turbine control systems, designed to ensure optimal performance and efficient operation of wind turbine generators. This mainboard is part of General Electric’s (GE) extensive range of industrial solutions and is specifically tailored for controlling the electrical and mechanical processes within wind turbines.

This mainboard plays a central role in the operation of wind turbine systems, monitoring and controlling various turbine functions such as pitch control, generator excitation, fault detection, and communication with other system components. Its compact size and highly reliable design make it an ideal choice for the demanding conditions of wind turbine environments, where constant and accurate performance is crucial.

The IS200WEORG1A board integrates seamlessly with the turbine’s larger control systems, offering exceptional durability, ease of integration, and efficient operation for both onshore and offshore wind turbine installations. It is built for robust performance, ensuring long-lasting support to wind turbine systems while minimizing downtime and maintenance costs.

Product Parameters

| Parameter | Specification |

|---|---|

| Dimensions | 178 x 51 x 305 mm |

| Weight | 0.5 kg |

| Type | Wind Turbine Mainboard |

| Power Supply | 24 V DC |

| Communication Protocol | Ethernet, Modbus |

| Operating Temperature | -40°C to +70°C |

| Mounting Type | DIN Rail |

| Application | Wind Turbine Systems |

| Compatibility | GE Wind Turbine Controllers |

Product Applications

The GE IS200WEORG1A Wind Turbine Mainboard is used primarily in wind turbine systems for controlling various mechanical and electrical components. Its applications are integral to both onshore and offshore wind turbines, providing reliable control over:

Pitch Control Systems: The board helps in controlling the blade pitch, adjusting the angle of the turbine blades to optimize the wind power capture and protect the turbine from high wind speeds.

Generator Excitation Control: The mainboard manages the excitation systems of the generator, ensuring smooth generation of electrical power while adjusting for load changes and system faults.

Wind Turbine Protection: It plays a role in the detection and diagnosis of faults or mechanical issues within the turbine, helping avoid system failures and reducing maintenance costs.

Data Communication and Monitoring: The IS200WEORG1A integrates with other control systems, facilitating remote monitoring and data collection, which allows operators to observe performance, troubleshoot problems, and optimize turbine efficiency.

Automation of Wind Turbine Systems: By controlling key turbine functions such as pitch adjustment, power regulation, and system health monitoring, the GE IS200WEORG1A ensures the turbine operates at peak efficiency with minimal human intervention.

Product Advantages

Durability: The IS200WEORG1A is designed to operate reliably in harsh environmental conditions, with a wide temperature operating range of -40°C to +70°C. Its sturdy construction ensures longevity, making it ideal for both onshore and offshore wind turbine environments.

Compact Design: With dimensions of 178 x 51 x 305 mm and a weight of only 0.5 kg, the mainboard has a compact form factor that makes it easy to integrate into wind turbine systems, saving valuable space in turbine control panels.

Advanced Communication: The IS200WEORG1A supports industry-standard communication protocols like Modbus and Ethernet, enabling seamless communication between the wind turbine’s control systems and other devices, facilitating remote monitoring and data transfer.

High Performance: The board is engineered for high precision and reliable performance. It ensures precise control over critical wind turbine functions such as pitch adjustment, power generation, and fault monitoring.

Flexibility: The IS200WEORG1A is designed to be compatible with other GE turbine controllers, offering flexibility for integrating with existing systems or replacing older components. Its compatibility with various communication protocols ensures it can be used in diverse wind turbine applications.

Energy Efficiency: The board optimizes the operation of wind turbines, helping achieve greater efficiency in wind power generation. Its smart design contributes to better energy capture, improved reliability, and reduced downtime.

Frequently Asked Questions (FAQ)

What is the total size of the Bently Nevada IS200WEORG1A mainboard?

-

The dimensions of the GE IS200WEORG1A mainboard are 178 x 51 x 305 mm.

-

What is the weight of the GE IS200WEORG1A mainboard?

-

The weight of the board is 0.5 kg.

-

What power supply does the IS200WEORG1A require?

-

The board operates on a 24 V DC power supply.

-

What communication protocols does the IS200WEORG1A support?

-

The IS200WEORG1A supports Ethernet and Modbus communication protocols for easy integration with other control systems.

-

What is the temperature range of the GE IS200WEORG1A mainboard?

-

The board can operate in environments with temperatures ranging from -40°C to +70°C.

-

What is the primary application of the IS200WEORG1A mainboard?

-

The board is primarily used in wind turbine systems, controlling functions such as pitch control, generator excitation, and monitoring turbine performance.

-

Can this board be used in offshore wind turbine systems?

-

Yes, the GE IS200WEORG1A is designed to operate in both onshore and offshore wind turbine environments.

-

How does the IS200WEORG1A contribute to wind turbine protection?

-

It detects and diagnoses faults in the turbine system, helping prevent damage and ensuring the turbine operates within safe limits.

-

Can the IS200WEORG1A be integrated with existing GE wind turbine controllers?

-

Yes, the IS200WEORG1A is compatible with GE wind turbine controllers, offering flexibility in integrating it into existing systems.

-

What are the advantages of using the IS200WEORG1A in wind turbine systems?

-

The advantages include improved system reliability, energy efficiency, reduced downtime, and enhanced remote monitoring capabilities.

-

General Electric IS200WEORG1A Wind Turbine Mainboard

Manufacturer:GE

Product Number:IS200WEORG1A

Product Type:Wind Turbine Mainboard

Origin:USA

Dimensions:178 x 51 x 305 mm

Weight:0.5 kg

Views:40

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200WEORG1A is a key component of wind turbine control systems, designed to ensure optimal performance and efficient operation of wind turbine generators. This mainboard is part of General Electric’s (GE) extensive range of industrial solutions and is specifically tailored for controlling the electrical and mechanical processes within wind turbines.

This mainboard plays a central role in the operation of wind turbine systems, monitoring and controlling various turbine functions such as pitch control, generator excitation, fault detection, and communication with other system components. Its compact size and highly reliable design make it an ideal choice for the demanding conditions of wind turbine environments, where constant and accurate performance is crucial.

The IS200WEORG1A board integrates seamlessly with the turbine’s larger control systems, offering exceptional durability, ease of integration, and efficient operation for both onshore and offshore wind turbine installations. It is built for robust performance, ensuring long-lasting support to wind turbine systems while minimizing downtime and maintenance costs.

Product Parameters

| Parameter | Specification |

|---|---|

| Dimensions | 178 x 51 x 305 mm |

| Weight | 0.5 kg |

| Type | Wind Turbine Mainboard |

| Power Supply | 24 V DC |

| Communication Protocol | Ethernet, Modbus |

| Operating Temperature | -40°C to +70°C |

| Mounting Type | DIN Rail |

| Application | Wind Turbine Systems |

| Compatibility | GE Wind Turbine Controllers |

Product Applications

The GE IS200WEORG1A Wind Turbine Mainboard is used primarily in wind turbine systems for controlling various mechanical and electrical components. Its applications are integral to both onshore and offshore wind turbines, providing reliable control over:

Pitch Control Systems: The board helps in controlling the blade pitch, adjusting the angle of the turbine blades to optimize the wind power capture and protect the turbine from high wind speeds.

Generator Excitation Control: The mainboard manages the excitation systems of the generator, ensuring smooth generation of electrical power while adjusting for load changes and system faults.

Wind Turbine Protection: It plays a role in the detection and diagnosis of faults or mechanical issues within the turbine, helping avoid system failures and reducing maintenance costs.

Data Communication and Monitoring: The IS200WEORG1A integrates with other control systems, facilitating remote monitoring and data collection, which allows operators to observe performance, troubleshoot problems, and optimize turbine efficiency.

Automation of Wind Turbine Systems: By controlling key turbine functions such as pitch adjustment, power regulation, and system health monitoring, the GE IS200WEORG1A ensures the turbine operates at peak efficiency with minimal human intervention.

Product Advantages

Durability: The IS200WEORG1A is designed to operate reliably in harsh environmental conditions, with a wide temperature operating range of -40°C to +70°C. Its sturdy construction ensures longevity, making it ideal for both onshore and offshore wind turbine environments.

Compact Design: With dimensions of 178 x 51 x 305 mm and a weight of only 0.5 kg, the mainboard has a compact form factor that makes it easy to integrate into wind turbine systems, saving valuable space in turbine control panels.

Advanced Communication: The IS200WEORG1A supports industry-standard communication protocols like Modbus and Ethernet, enabling seamless communication between the wind turbine’s control systems and other devices, facilitating remote monitoring and data transfer.

High Performance: The board is engineered for high precision and reliable performance. It ensures precise control over critical wind turbine functions such as pitch adjustment, power generation, and fault monitoring.

Flexibility: The IS200WEORG1A is designed to be compatible with other GE turbine controllers, offering flexibility for integrating with existing systems or replacing older components. Its compatibility with various communication protocols ensures it can be used in diverse wind turbine applications.

Energy Efficiency: The board optimizes the operation of wind turbines, helping achieve greater efficiency in wind power generation. Its smart design contributes to better energy capture, improved reliability, and reduced downtime.

Frequently Asked Questions (FAQ)

What is the total size of the Bently Nevada IS200WEORG1A mainboard?

-

The dimensions of the GE IS200WEORG1A mainboard are 178 x 51 x 305 mm.

-

What is the weight of the GE IS200WEORG1A mainboard?

-

The weight of the board is 0.5 kg.

-

What power supply does the IS200WEORG1A require?

-

The board operates on a 24 V DC power supply.

-

What communication protocols does the IS200WEORG1A support?

-

The IS200WEORG1A supports Ethernet and Modbus communication protocols for easy integration with other control systems.

-

What is the temperature range of the GE IS200WEORG1A mainboard?

-

The board can operate in environments with temperatures ranging from -40°C to +70°C.

-

What is the primary application of the IS200WEORG1A mainboard?

-

The board is primarily used in wind turbine systems, controlling functions such as pitch control, generator excitation, and monitoring turbine performance.

-

Can this board be used in offshore wind turbine systems?

-

Yes, the GE IS200WEORG1A is designed to operate in both onshore and offshore wind turbine environments.

-

How does the IS200WEORG1A contribute to wind turbine protection?

-

It detects and diagnoses faults in the turbine system, helping prevent damage and ensuring the turbine operates within safe limits.

-

Can the IS200WEORG1A be integrated with existing GE wind turbine controllers?

-

Yes, the IS200WEORG1A is compatible with GE wind turbine controllers, offering flexibility in integrating it into existing systems.

-

What are the advantages of using the IS200WEORG1A in wind turbine systems?

-

The advantages include improved system reliability, energy efficiency, reduced downtime, and enhanced remote monitoring capabilities.

-

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...