Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

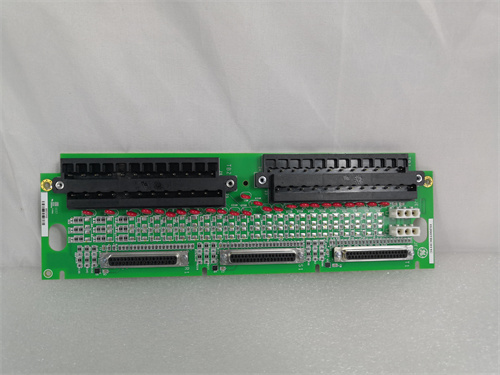

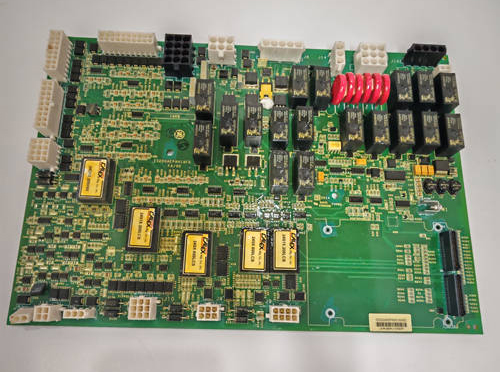

General Electric IS215UCVGM06A Universal Control Variable Generator Module

Manufacturer:GE

Product Number:IS215UCVGM06A

Product Type:Universal Control Variable Generator Module

Origin:USA

Dimensions:162 x 86 mm

Weight:1.2 kg

Views:32

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

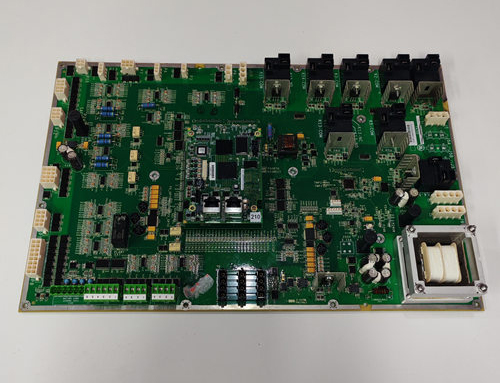

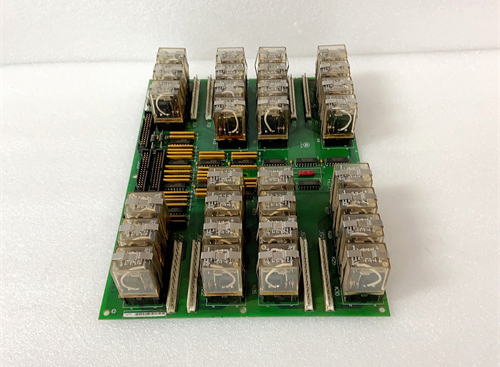

The GE IS215UCVGM06A Universal Control Variable Generator Module is an advanced industrial control module designed for use in GE Mark VIe and Mark VI turbine and process control systems—both part of the globally renowned GE Speedtronic™ family of automation platforms.

As a Universal Control Variable Generator (UCVG) Module, the IS215UCVGM06A performs critical control and signal processing functions, serving as a central processor for generating, manipulating, and distributing variable control signals to support a wide range of process control applications. It ensures seamless real-time execution of control logic for complex machinery such as gas turbines, steam turbines, balance of plant (BoP) systems, and auxiliary equipment.

This module is built with a high-performance CPU, robust industrial-grade memory, and a deterministic real-time operating system, which together guarantee fast processing speeds, high reliability, and consistent response times under demanding operational conditions. The UCVG design allows it to integrate easily into VMEbus-based GE control racks, making it a flexible and scalable solution for industrial environments where uptime and precision control are critical.

The IS215UCVGM06A is trusted worldwide by operators of power plants, oil & gas platforms, chemical processing facilities, and heavy manufacturing plants—where it contributes to optimal machine performance and overall system efficiency.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | GE IS215UCVGM06A Universal Control Variable Generator Module |

| Part Number | IS215UCVGM06A |

| System Compatibility | GE Mark VI, Mark VIe, Speedtronic™ |

| Module Type | Universal Control Variable Generator (UCVG) |

| Processor | High-performance industrial CPU |

| Memory | SDRAM and flash memory |

| Operating System | Deterministic real-time embedded OS |

| Slot Requirement | Single-slot VMEbus rack module |

| Communication Interfaces | Ethernet 10/100 Mbps, Serial, VMEbus |

| Supported Protocols | Ethernet, Modbus, proprietary GE protocols |

| Control Applications | Gas/steam turbine control, BoP systems, auxiliary equipment control |

| Time Synchronization | NTP, GPS capable |

| Redundancy Support | Yes — dual redundant configurations supported |

| Data Logging | Yes — onboard data logging and diagnostics |

| Firmware Upgrade | Field upgradeable firmware via Ethernet |

| Diagnostics | Onboard self-tests and diagnostics |

| Power Supply | 5 VDC via VME backplane |

| Power Consumption | Approx. 18 W typical |

| Operating Temperature Range | -30°C to +65°C (-22°F to +149°F) |

| Storage Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Relative Humidity Range | 5% to 95% RH (non-condensing) |

| Vibration Compliance | IEC 60068-2-6 |

| Shock Compliance | IEC 60068-2-27 |

| PCB Protection | Conformal-coated for industrial environments |

| Dimensions (H x W x D) | 162 x 86 mm |

| Weight | 1.2 kg |

| Mounting Method | Single-slot VME chassis or rack mount |

| Certifications | CE, UL, CSA, RoHS compliant |

Applications

Gas turbine process control and automation

Steam turbine performance and protection systems

Balance of Plant (BoP) equipment control and optimization

-

Advanced auxiliary equipment control and diagnostics

Industrial process control in oil refineries

Power generation plants (gas, coal, nuclear, hydroelectric)

-

Distributed control systems (DCS) in chemical processing plants

-

Automation of marine propulsion and power systems

-

Process optimization in mining and materials processing industries

-

Variable generator control for complex manufacturing processes

Product Advantages

Universal control capability: Adaptable to many process variables across diverse industries

Fast real-time processing: Deterministic operation supports precise control loops

Industrial-grade CPU and memory: Designed for long-term reliability in critical applications

Compact design: Saves space in VME-based racks with single-slot footprint

Seamless integration: Fully compatible with Mark VIe and Mark VI systems

Redundant architecture: Supports dual-controller configurations for maximum uptime

Field upgradeable: Firmware can be updated without major downtime

Industrial durability: Conformal-coated PCB ensures resistance to dust, moisture, and chemicals

Global compliance: CE, UL, CSA certified for international applications

Proven reliability: Used worldwide in mission-critical turbine control systems

Frequently Asked Questions (FAQ)

What is the primary function of the IS215UCVGM06A?

It generates and manages control variable signals for complex turbine and process control systems.

Which GE platforms is it compatible with?

It is fully compatible with Mark VIe and Mark VI platforms.

Does it support redundant controller configurations?

Yes — it supports redundant control configurations for high-reliability systems.

What communication ports are available?

Ethernet (10/100 Mbps), serial, and VMEbus connections are supported.

What is the power consumption of the module?

Approx. 18 W typical.

What industries commonly use this module?

Power generation, oil & gas, chemical processing, and manufacturing industries.

How is the module protected against harsh environments?

The PCB is conformal-coated to resist moisture, dust, and corrosives.

Is the firmware upgradeable?

Yes — firmware upgrades can be performed in the field via Ethernet.

Does the board support diagnostic functions?

Yes — it features onboard self-tests and system diagnostics.

What type of memory is used?

The module uses SDRAM for real-time control and flash memory for persistent storage.

General Electric IS215UCVGM06A Universal Control Variable Generator Module

Manufacturer:GE

Product Number:IS215UCVGM06A

Product Type:Universal Control Variable Generator Module

Origin:USA

Dimensions:162 x 86 mm

Weight:1.2 kg

Views:32

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS215UCVGM06A Universal Control Variable Generator Module is an advanced industrial control module designed for use in GE Mark VIe and Mark VI turbine and process control systems—both part of the globally renowned GE Speedtronic™ family of automation platforms.

As a Universal Control Variable Generator (UCVG) Module, the IS215UCVGM06A performs critical control and signal processing functions, serving as a central processor for generating, manipulating, and distributing variable control signals to support a wide range of process control applications. It ensures seamless real-time execution of control logic for complex machinery such as gas turbines, steam turbines, balance of plant (BoP) systems, and auxiliary equipment.

This module is built with a high-performance CPU, robust industrial-grade memory, and a deterministic real-time operating system, which together guarantee fast processing speeds, high reliability, and consistent response times under demanding operational conditions. The UCVG design allows it to integrate easily into VMEbus-based GE control racks, making it a flexible and scalable solution for industrial environments where uptime and precision control are critical.

The IS215UCVGM06A is trusted worldwide by operators of power plants, oil & gas platforms, chemical processing facilities, and heavy manufacturing plants—where it contributes to optimal machine performance and overall system efficiency.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | GE IS215UCVGM06A Universal Control Variable Generator Module |

| Part Number | IS215UCVGM06A |

| System Compatibility | GE Mark VI, Mark VIe, Speedtronic™ |

| Module Type | Universal Control Variable Generator (UCVG) |

| Processor | High-performance industrial CPU |

| Memory | SDRAM and flash memory |

| Operating System | Deterministic real-time embedded OS |

| Slot Requirement | Single-slot VMEbus rack module |

| Communication Interfaces | Ethernet 10/100 Mbps, Serial, VMEbus |

| Supported Protocols | Ethernet, Modbus, proprietary GE protocols |

| Control Applications | Gas/steam turbine control, BoP systems, auxiliary equipment control |

| Time Synchronization | NTP, GPS capable |

| Redundancy Support | Yes — dual redundant configurations supported |

| Data Logging | Yes — onboard data logging and diagnostics |

| Firmware Upgrade | Field upgradeable firmware via Ethernet |

| Diagnostics | Onboard self-tests and diagnostics |

| Power Supply | 5 VDC via VME backplane |

| Power Consumption | Approx. 18 W typical |

| Operating Temperature Range | -30°C to +65°C (-22°F to +149°F) |

| Storage Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Relative Humidity Range | 5% to 95% RH (non-condensing) |

| Vibration Compliance | IEC 60068-2-6 |

| Shock Compliance | IEC 60068-2-27 |

| PCB Protection | Conformal-coated for industrial environments |

| Dimensions (H x W x D) | 162 x 86 mm |

| Weight | 1.2 kg |

| Mounting Method | Single-slot VME chassis or rack mount |

| Certifications | CE, UL, CSA, RoHS compliant |

Applications

Gas turbine process control and automation

Steam turbine performance and protection systems

Balance of Plant (BoP) equipment control and optimization

-

Advanced auxiliary equipment control and diagnostics

Industrial process control in oil refineries

Power generation plants (gas, coal, nuclear, hydroelectric)

-

Distributed control systems (DCS) in chemical processing plants

-

Automation of marine propulsion and power systems

-

Process optimization in mining and materials processing industries

-

Variable generator control for complex manufacturing processes

Product Advantages

Universal control capability: Adaptable to many process variables across diverse industries

Fast real-time processing: Deterministic operation supports precise control loops

Industrial-grade CPU and memory: Designed for long-term reliability in critical applications

Compact design: Saves space in VME-based racks with single-slot footprint

Seamless integration: Fully compatible with Mark VIe and Mark VI systems

Redundant architecture: Supports dual-controller configurations for maximum uptime

Field upgradeable: Firmware can be updated without major downtime

Industrial durability: Conformal-coated PCB ensures resistance to dust, moisture, and chemicals

Global compliance: CE, UL, CSA certified for international applications

Proven reliability: Used worldwide in mission-critical turbine control systems

Frequently Asked Questions (FAQ)

What is the primary function of the IS215UCVGM06A?

It generates and manages control variable signals for complex turbine and process control systems.

Which GE platforms is it compatible with?

It is fully compatible with Mark VIe and Mark VI platforms.

Does it support redundant controller configurations?

Yes — it supports redundant control configurations for high-reliability systems.

What communication ports are available?

Ethernet (10/100 Mbps), serial, and VMEbus connections are supported.

What is the power consumption of the module?

Approx. 18 W typical.

What industries commonly use this module?

Power generation, oil & gas, chemical processing, and manufacturing industries.

How is the module protected against harsh environments?

The PCB is conformal-coated to resist moisture, dust, and corrosives.

Is the firmware upgradeable?

Yes — firmware upgrades can be performed in the field via Ethernet.

Does the board support diagnostic functions?

Yes — it features onboard self-tests and system diagnostics.

What type of memory is used?

The module uses SDRAM for real-time control and flash memory for persistent storage.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...