Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

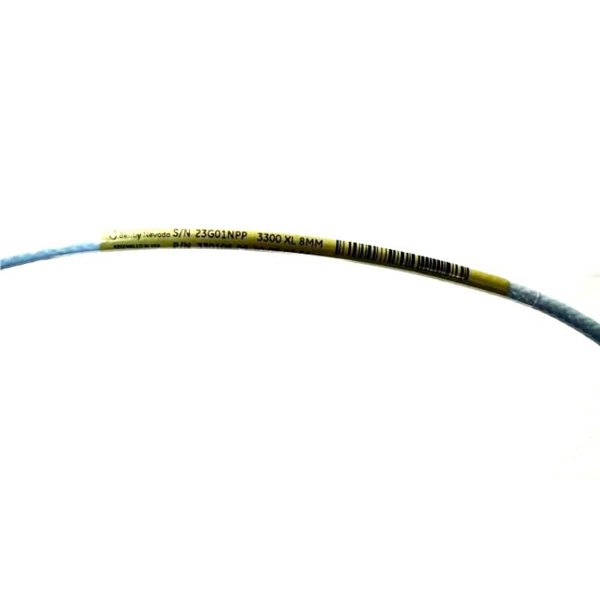

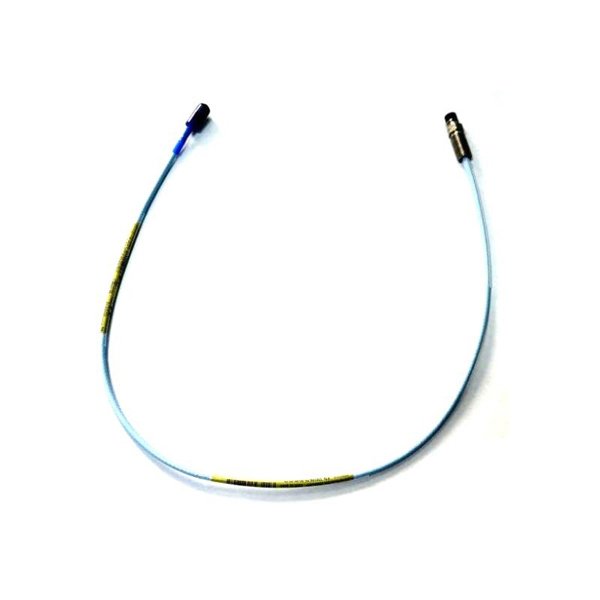

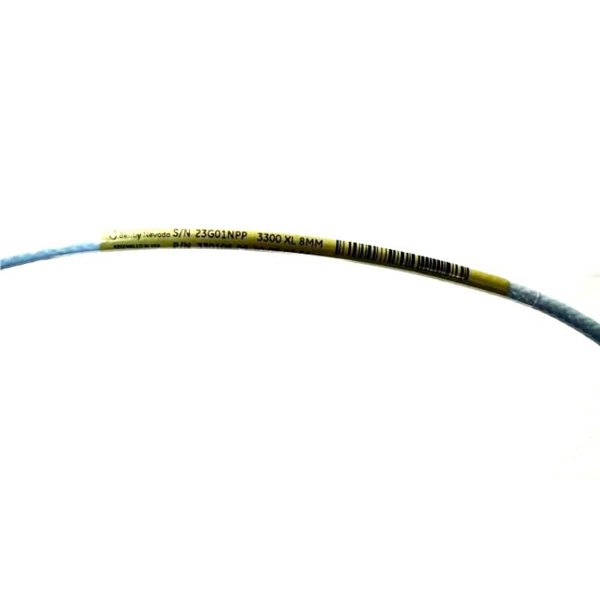

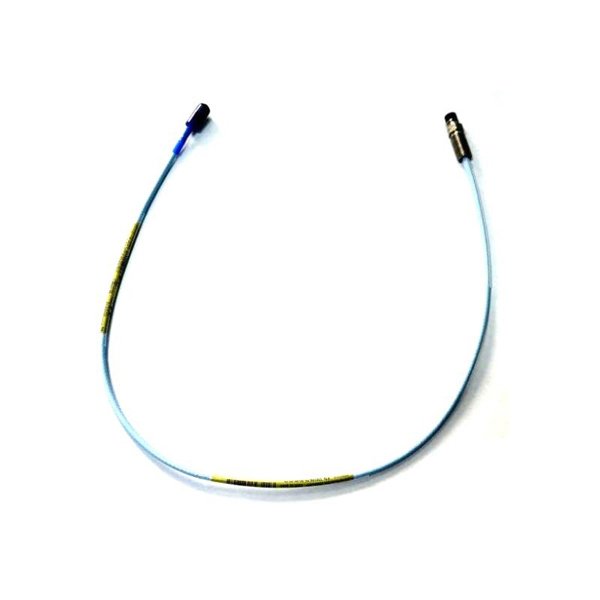

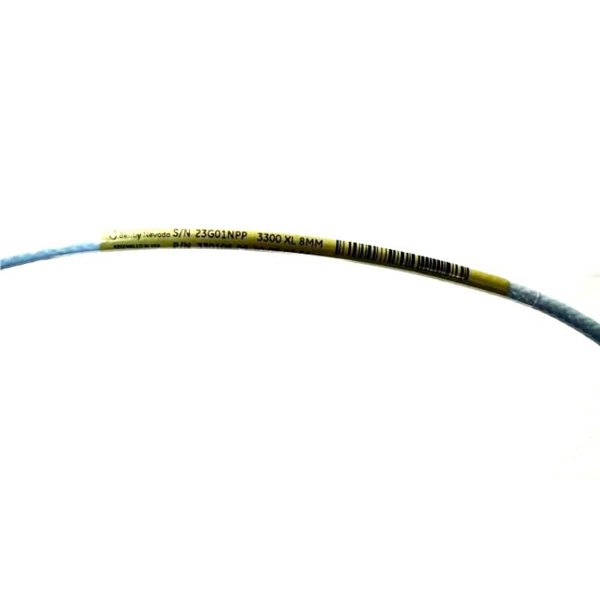

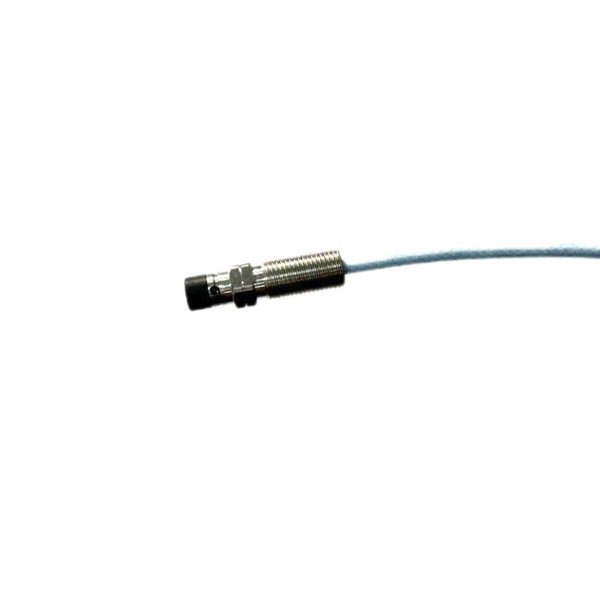

Bently Nevada 330106-05 3300 XL 8mm Reverse Mount Probe

Manufacturer:Bently Nevada

Product Number:330106-05

Condition:3300 XL 8mm Reverse Mount Probe

Origin:USA

Cable length:0.5 m

Weight:0.162 kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

Its rugged design ensures performance consistency under extreme conditions such as high temperatures, mechanical stress, and contamination. The probe is typically used to detect the relative motion of rotating shafts, enabling early detection of mechanical issues such as imbalance, misalignment, or shaft rub.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | Bently Nevada 330106-05 |

| Series | 3300 XL |

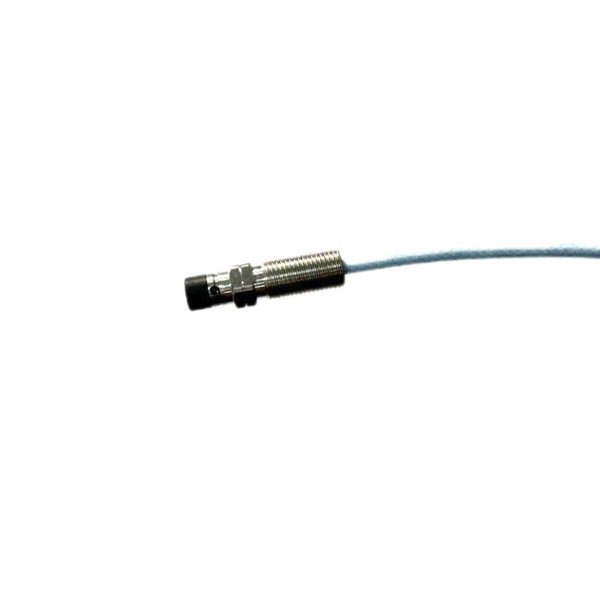

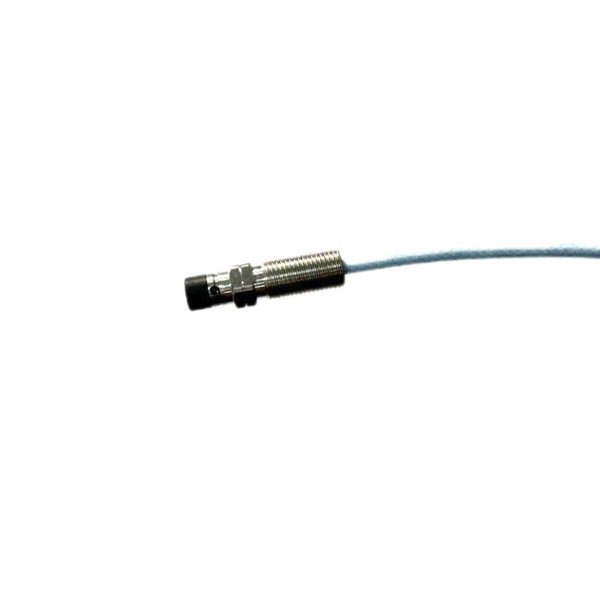

| Probe Type | Proximity Probe |

| Tip Material | Polyphenylene Sulfide (PPS) |

| Body Material | AISI 303 Stainless Steel |

| Thread Size | 3/8-24 UNF-2A |

| Connector Type | Miniature coaxial (male) |

| Probe Length | 5 meters (varies with model) |

| Sensitivity | 7.87 mV/μm (200 mV/mil) |

| Frequency Response | Up to 10 kHz |

| Operating Temperature Range | -35°C to +177°C (-31°F to +350°F) |

| Storage Temperature Range | -51°C to +177°C (-60°F to +350°F) |

| Maximum Pressure Resistance | 300 psi |

| Environmental Sealing | Epoxy-sealed tip |

| Weight | 0.162 kg |

| Cable length | 0.5 m |

Product Applications

The 330106-05 is widely used in various industries that rely on precision rotating equipment. Applications include:

Steam turbines – Shaft vibration and position monitoring

Gas turbines – Early detection of rotor misalignment or rubbing

Compressors and expanders – Dynamic shaft behavior tracking

Industrial pumps – Monitoring shaft deflection and wear

Gearboxes and motors – Real-time vibration measurement

Hydroelectric units – Ensuring operational balance and alignment

It is commonly integrated into machine protection systems for real-time diagnostics, helping prevent unplanned outages.

Product Advantages

High Accuracy and Sensitivity

Provides precise shaft vibration and position measurement down to micron levels, ideal for protection systems.

Rugged Industrial Design

Withstands harsh environments, high temperatures, and mechanical stresses with minimal signal drift.

Interchangeability

Compatible with other Bently Nevada proximity transducer systems, enabling flexible maintenance and upgrade paths.

Long-Term Stability

Offers excellent long-term calibration stability, reducing downtime and recalibration frequency.

Broad Compatibility

Works with 3300 XL Proximitor Sensor and extension cables, supporting a wide variety of industrial configurations.

Ease of Installation

Threaded housing and compact size allow flexible and secure mounting options in limited spaces.

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the 330106-05 probe?

A1: It measures the dynamic and static displacement of a shaft relative to its bearing, used for vibration monitoring.

Q2: Can it operate in high-temperature environments?

A2: Yes. It can operate in environments up to 177°C (350°F), making it suitable for turbine and compressor applications.

Q3: Is the 330106-05 compatible with all 3300 XL Proximitor Sensors?

A3: Yes, it is designed to work specifically with Bently Nevada 3300 XL Proximitor Sensors.

Q4: What type of machinery benefits from using this sensor?

A4: Rotating machinery such as turbines, compressors, pumps, and motors all benefit from its precise monitoring capabilities.

Q5: What type of signal does this probe produce?

A5: It produces a voltage signal proportional to the gap (distance) between the probe tip and the shaft surface.

Q6: Can this probe detect shaft rub conditions?

A6: Yes, it can detect both intermittent and continuous rubs by monitoring displacement and vibration changes.

Q7: How should the probe be mounted?

A7: It is mounted using its threaded housing, generally perpendicular to the shaft surface being monitored.

Q8: What material is used in the probe tip?

A8: The tip is made of polyphenylene sulfide (PPS), offering good resistance to heat and chemical exposure.

Q9: Does the probe require periodic recalibration?

A9: While designed for long-term stability, recalibration may be needed based on usage, especially in harsh environments.

Q10: Is the cable length customizable?

A10: Yes, different cable lengths are available (typically 1 to 9 meters) depending on system layout requirements.

Bently Nevada 330106-05 3300 XL 8mm Reverse Mount Probe

Manufacturer:Bently Nevada

Product Number:330106-05

Condition:3300 XL 8mm Reverse Mount Probe

Origin:USA

Cable length:0.5 m

Weight:0.162 kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

Its rugged design ensures performance consistency under extreme conditions such as high temperatures, mechanical stress, and contamination. The probe is typically used to detect the relative motion of rotating shafts, enabling early detection of mechanical issues such as imbalance, misalignment, or shaft rub.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | Bently Nevada 330106-05 |

| Series | 3300 XL |

| Probe Type | Proximity Probe |

| Tip Material | Polyphenylene Sulfide (PPS) |

| Body Material | AISI 303 Stainless Steel |

| Thread Size | 3/8-24 UNF-2A |

| Connector Type | Miniature coaxial (male) |

| Probe Length | 5 meters (varies with model) |

| Sensitivity | 7.87 mV/μm (200 mV/mil) |

| Frequency Response | Up to 10 kHz |

| Operating Temperature Range | -35°C to +177°C (-31°F to +350°F) |

| Storage Temperature Range | -51°C to +177°C (-60°F to +350°F) |

| Maximum Pressure Resistance | 300 psi |

| Environmental Sealing | Epoxy-sealed tip |

| Weight | 0.162 kg |

| Cable length | 0.5 m |

Product Applications

The 330106-05 is widely used in various industries that rely on precision rotating equipment. Applications include:

Steam turbines – Shaft vibration and position monitoring

Gas turbines – Early detection of rotor misalignment or rubbing

Compressors and expanders – Dynamic shaft behavior tracking

Industrial pumps – Monitoring shaft deflection and wear

Gearboxes and motors – Real-time vibration measurement

Hydroelectric units – Ensuring operational balance and alignment

It is commonly integrated into machine protection systems for real-time diagnostics, helping prevent unplanned outages.

Product Advantages

High Accuracy and Sensitivity

Provides precise shaft vibration and position measurement down to micron levels, ideal for protection systems.

Rugged Industrial Design

Withstands harsh environments, high temperatures, and mechanical stresses with minimal signal drift.

Interchangeability

Compatible with other Bently Nevada proximity transducer systems, enabling flexible maintenance and upgrade paths.

Long-Term Stability

Offers excellent long-term calibration stability, reducing downtime and recalibration frequency.

Broad Compatibility

Works with 3300 XL Proximitor Sensor and extension cables, supporting a wide variety of industrial configurations.

Ease of Installation

Threaded housing and compact size allow flexible and secure mounting options in limited spaces.

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the 330106-05 probe?

A1: It measures the dynamic and static displacement of a shaft relative to its bearing, used for vibration monitoring.

Q2: Can it operate in high-temperature environments?

A2: Yes. It can operate in environments up to 177°C (350°F), making it suitable for turbine and compressor applications.

Q3: Is the 330106-05 compatible with all 3300 XL Proximitor Sensors?

A3: Yes, it is designed to work specifically with Bently Nevada 3300 XL Proximitor Sensors.

Q4: What type of machinery benefits from using this sensor?

A4: Rotating machinery such as turbines, compressors, pumps, and motors all benefit from its precise monitoring capabilities.

Q5: What type of signal does this probe produce?

A5: It produces a voltage signal proportional to the gap (distance) between the probe tip and the shaft surface.

Q6: Can this probe detect shaft rub conditions?

A6: Yes, it can detect both intermittent and continuous rubs by monitoring displacement and vibration changes.

Q7: How should the probe be mounted?

A7: It is mounted using its threaded housing, generally perpendicular to the shaft surface being monitored.

Q8: What material is used in the probe tip?

A8: The tip is made of polyphenylene sulfide (PPS), offering good resistance to heat and chemical exposure.

Q9: Does the probe require periodic recalibration?

A9: While designed for long-term stability, recalibration may be needed based on usage, especially in harsh environments.

Q10: Is the cable length customizable?

A10: Yes, different cable lengths are available (typically 1 to 9 meters) depending on system layout requirements.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...