Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

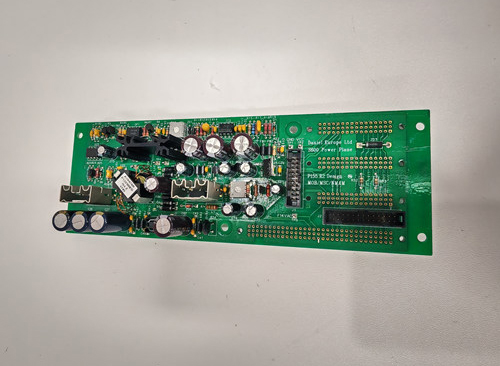

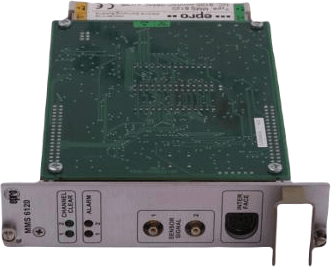

Emerson KJ2002X1-CA1 Controller Module

Manufacturer:Emerson

Product Number:KJ2002X1-CA1

Product Type:Controller Module

Origin:USA

Dimensions:250 x 200 x 100 mm

Weight:2.5kg

Views:110

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

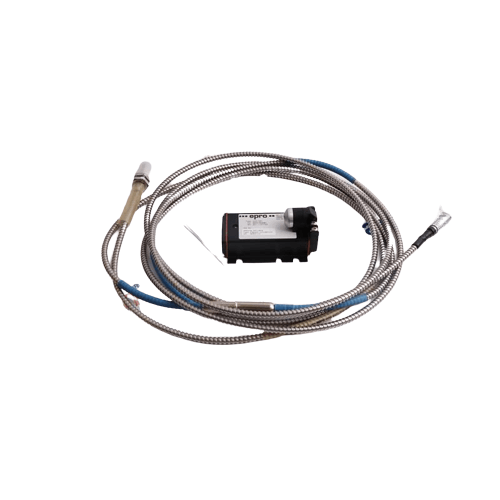

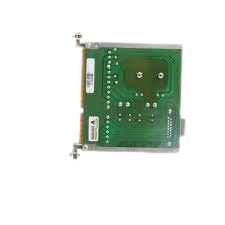

The Emerson KJ2002X1-CA1 Controller Module is a key component of the DeltaV™ distributed control system (DCS). It is designed to provide robust, deterministic control for continuous and batch processes in a wide range of industries. The controller manages the execution of control strategies, monitors field devices, communicates with I/O modules, and provides reliable real-time control performance.

Engineered for mission-critical applications, the KJ2002X1-CA1 supports redundant configurations and hot-swappable capabilities, ensuring system availability and ease of maintenance. It also incorporates DeltaV’s powerful diagnostics and automatic configuration features, reducing downtime and engineering effort.

Key Features

-

High-performance real-time control with deterministic processing

Supports complex control strategies, including regulatory, sequential, and batch

Integrated with DeltaV system architecture for seamless operation

Redundant-ready for maximum availability

Hot-swappable for non-disruptive maintenance

-

Built-in self-diagnostics and status indicators

-

Compact, modular design ideal for distributed installations

-

Easy integration with Ethernet and fieldbus networks

Technical Specifications

| Item | Specification |

|---|---|

| Product Type | Controller Module |

| Model Number | KJ2002X1-CA1 |

| System Compatibility | Emerson DeltaV™ System |

| Processor | High-performance embedded processor |

| Control Execution | Deterministic, event-driven execution loop |

| Communication Ports | Ethernet, Serial (RS-232), DeltaV Control Network |

| Memory | Internal memory for control strategy execution |

| Redundancy | Supports redundant controller configurations |

| Hot Swappable | Yes |

| Status Indicators | LEDs for power, status, communication, and diagnostics |

| Power Supply Voltage | Supplied via DeltaV baseplate (typically 24 VDC) |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% RH (non-condensing) |

| Mounting | DIN rail via DeltaV carrier |

| Dimensions | 250 x 200 x 100 mm |

| Weight | 2.5 kg |

| Certifications | CE, UL, CSA, ATEX, RoHS |

Industry Applications

Oil and Gas Processing

Chemical Manufacturing

Pharmaceutical Production

Power Generation and Utilities

Food and Beverage Automation

Metals and Mining Operations

Water and Wastewater Treatment

Advantages

Reliable and scalable process control for small to large systems

Reduces downtime with hot-swapping and diagnostics

Easily integrates with DeltaV I/O and communication networks

Ensures safety and reliability with redundant architecture

Simplifies engineering through plug-and-play and auto-detection

Flexible deployment with wide environmental tolerance

Frequently Asked Questions (FAQ)

What is the main function of the KJ2002X1-CA1?

It acts as the central processing unit in a DeltaV system, executing control logic and managing I/O and communication.

Can the KJ2002X1-CA1 be used in a redundant configuration?

Yes, it supports redundancy for high-availability applications.

Is the module hot-swappable?

Yes, it can be replaced without shutting down the system.

What control types does it support?

It supports regulatory, sequential, batch, and advanced control strategies.

How does it connect to the rest of the DeltaV system?

Via the DeltaV control network using a standard backplane and Ethernet.

Does it include status LEDs?

Yes, it includes LEDs for power, health, and communication diagnostics.

What power supply is required?

It receives power via the DeltaV backplane, typically 24 VDC.

What environments is it suitable for?

Designed for harsh industrial conditions: -40°C to +70°C, 5–95% RH.

What certifications does it hold?

It is certified for CE, UL, CSA, ATEX, and RoHS compliance.

Is it compatible with legacy DeltaV hardware?

Yes, it integrates seamlessly with existing DeltaV infrastructures.

Emerson KJ2002X1-CA1 Controller Module

Manufacturer:Emerson

Product Number:KJ2002X1-CA1

Product Type:Controller Module

Origin:USA

Dimensions:250 x 200 x 100 mm

Weight:2.5kg

Views:110

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Emerson KJ2002X1-CA1 Controller Module is a key component of the DeltaV™ distributed control system (DCS). It is designed to provide robust, deterministic control for continuous and batch processes in a wide range of industries. The controller manages the execution of control strategies, monitors field devices, communicates with I/O modules, and provides reliable real-time control performance.

Engineered for mission-critical applications, the KJ2002X1-CA1 supports redundant configurations and hot-swappable capabilities, ensuring system availability and ease of maintenance. It also incorporates DeltaV’s powerful diagnostics and automatic configuration features, reducing downtime and engineering effort.

Key Features

-

High-performance real-time control with deterministic processing

Supports complex control strategies, including regulatory, sequential, and batch

Integrated with DeltaV system architecture for seamless operation

Redundant-ready for maximum availability

Hot-swappable for non-disruptive maintenance

-

Built-in self-diagnostics and status indicators

-

Compact, modular design ideal for distributed installations

-

Easy integration with Ethernet and fieldbus networks

Technical Specifications

| Item | Specification |

|---|---|

| Product Type | Controller Module |

| Model Number | KJ2002X1-CA1 |

| System Compatibility | Emerson DeltaV™ System |

| Processor | High-performance embedded processor |

| Control Execution | Deterministic, event-driven execution loop |

| Communication Ports | Ethernet, Serial (RS-232), DeltaV Control Network |

| Memory | Internal memory for control strategy execution |

| Redundancy | Supports redundant controller configurations |

| Hot Swappable | Yes |

| Status Indicators | LEDs for power, status, communication, and diagnostics |

| Power Supply Voltage | Supplied via DeltaV baseplate (typically 24 VDC) |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% RH (non-condensing) |

| Mounting | DIN rail via DeltaV carrier |

| Dimensions | 250 x 200 x 100 mm |

| Weight | 2.5 kg |

| Certifications | CE, UL, CSA, ATEX, RoHS |

Industry Applications

Oil and Gas Processing

Chemical Manufacturing

Pharmaceutical Production

Power Generation and Utilities

Food and Beverage Automation

Metals and Mining Operations

Water and Wastewater Treatment

Advantages

Reliable and scalable process control for small to large systems

Reduces downtime with hot-swapping and diagnostics

Easily integrates with DeltaV I/O and communication networks

Ensures safety and reliability with redundant architecture

Simplifies engineering through plug-and-play and auto-detection

Flexible deployment with wide environmental tolerance

Frequently Asked Questions (FAQ)

What is the main function of the KJ2002X1-CA1?

It acts as the central processing unit in a DeltaV system, executing control logic and managing I/O and communication.

Can the KJ2002X1-CA1 be used in a redundant configuration?

Yes, it supports redundancy for high-availability applications.

Is the module hot-swappable?

Yes, it can be replaced without shutting down the system.

What control types does it support?

It supports regulatory, sequential, batch, and advanced control strategies.

How does it connect to the rest of the DeltaV system?

Via the DeltaV control network using a standard backplane and Ethernet.

Does it include status LEDs?

Yes, it includes LEDs for power, health, and communication diagnostics.

What power supply is required?

It receives power via the DeltaV backplane, typically 24 VDC.

What environments is it suitable for?

Designed for harsh industrial conditions: -40°C to +70°C, 5–95% RH.

What certifications does it hold?

It is certified for CE, UL, CSA, ATEX, and RoHS compliance.

Is it compatible with legacy DeltaV hardware?

Yes, it integrates seamlessly with existing DeltaV infrastructures.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...