Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

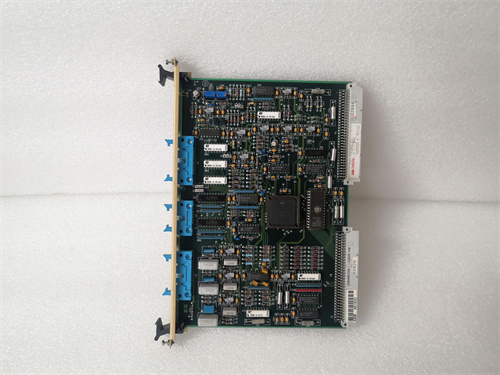

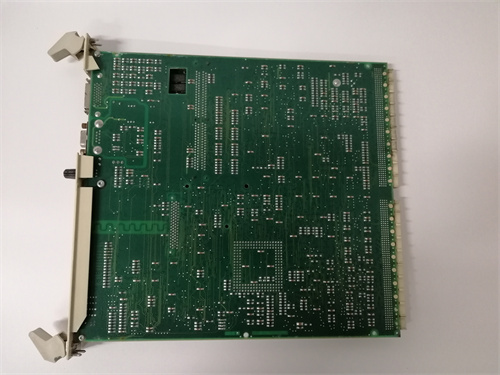

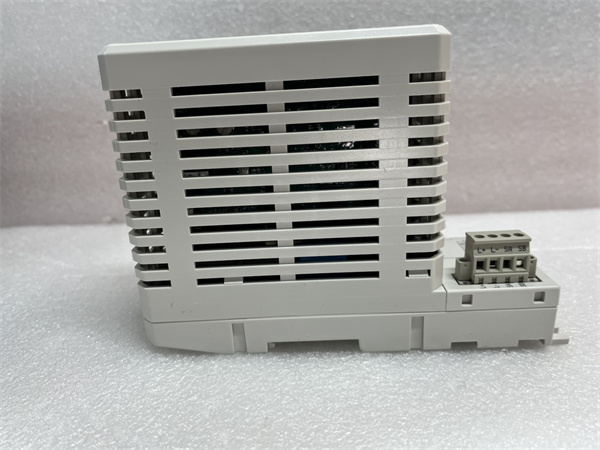

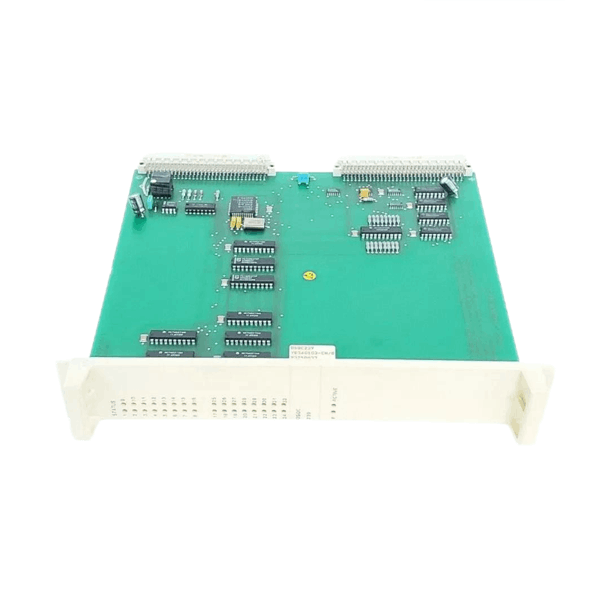

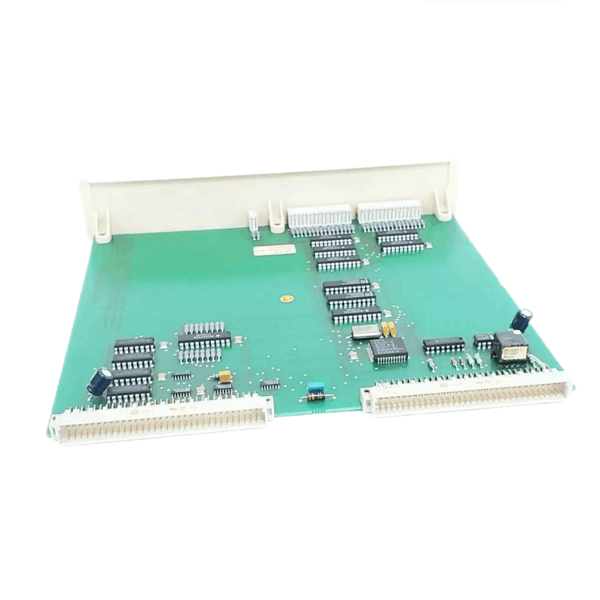

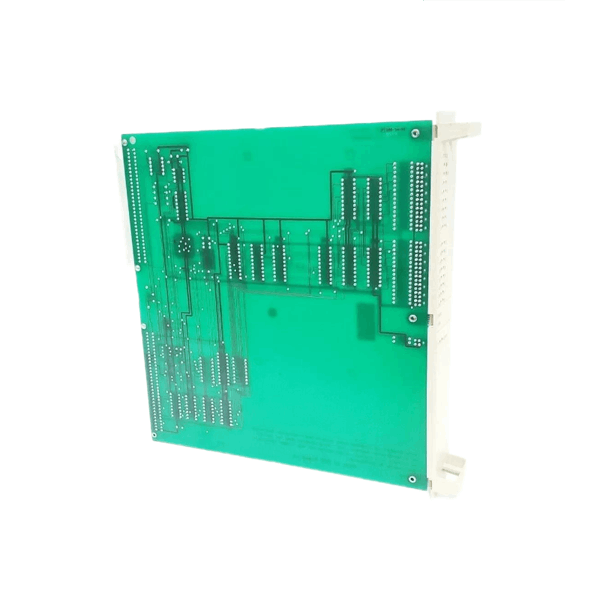

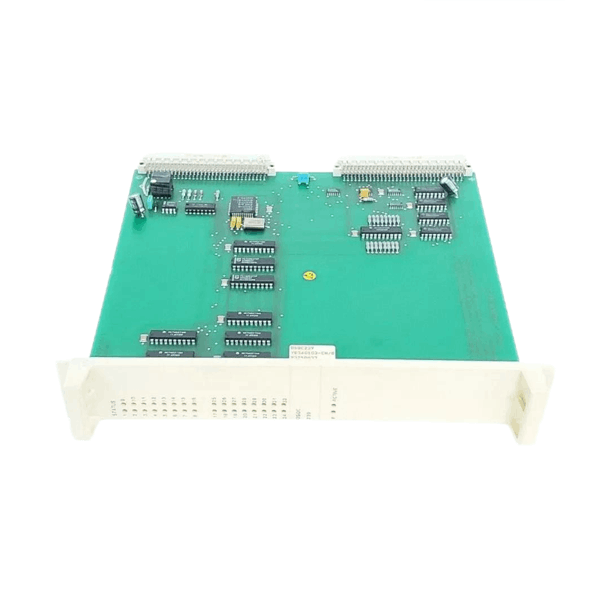

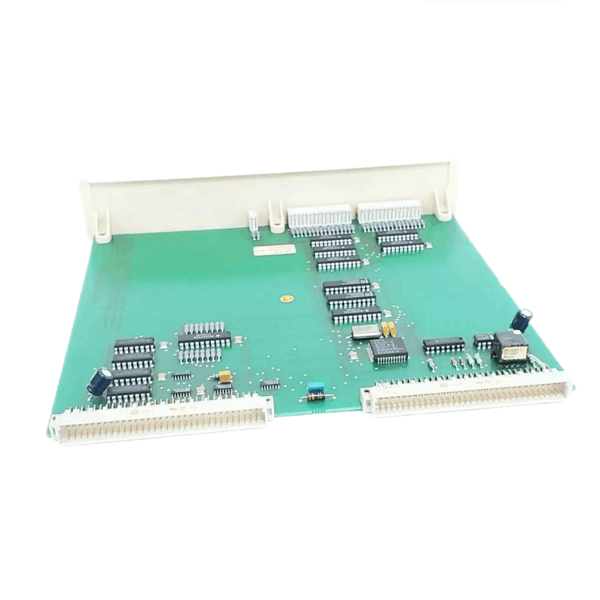

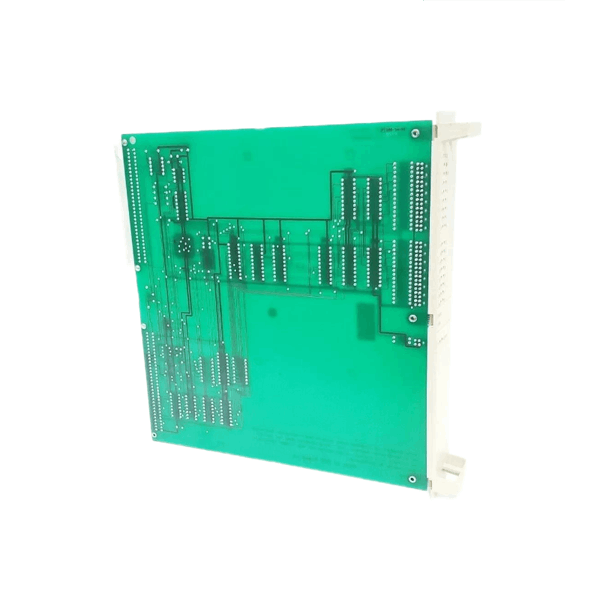

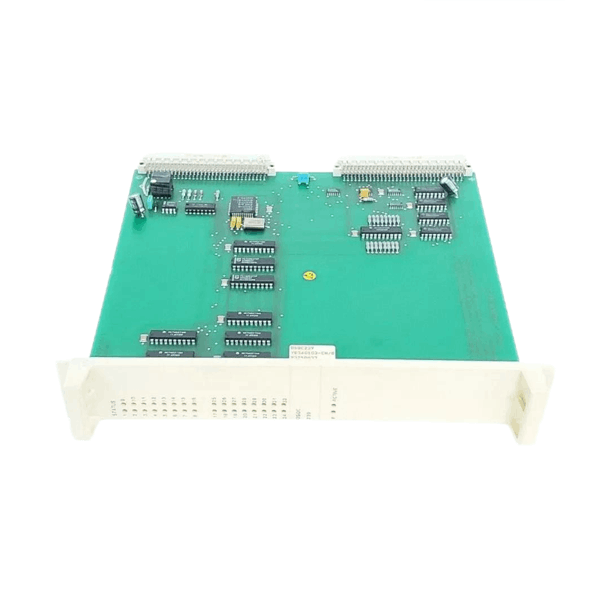

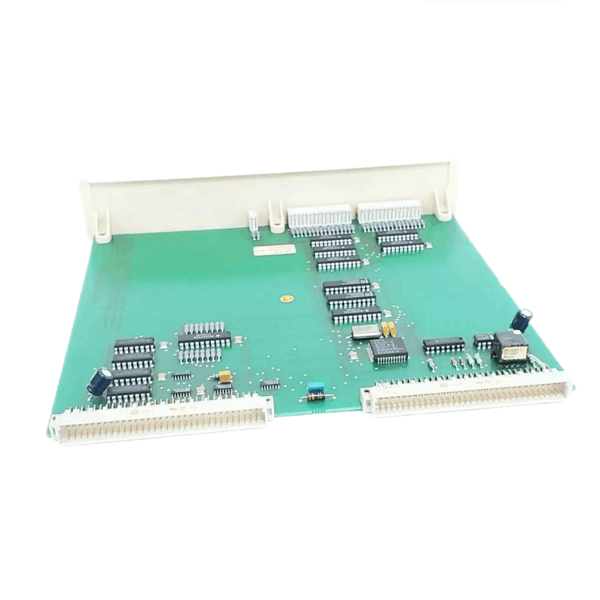

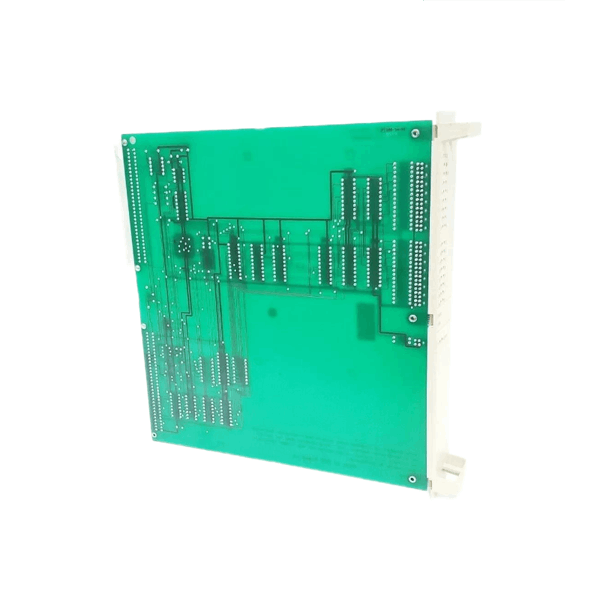

ABB DSQC239 YB560103-CH Robot Remote I/O Module

Manufacturer:ABB

Product Number:DSQC239 YB560103-CH

Product Type:Robot Remote I/O Module

Origin:Sweden

Dimensions:200 x 120 x 60mm

Weight:2.5kg

Views:40

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB DSQC239 (YB560103-CH) is a versatile Robot Remote I/O Module designed to expand the input/output capabilities of ABB robot controllers. This module enables seamless integration of additional sensors, actuators, and peripheral devices into the robot control system, allowing for enhanced automation flexibility and improved process control.

Engineered for industrial environments, the DSQC239 supports fast, reliable communication with the main controller, facilitating real-time data exchange and synchronized operation of robotic and peripheral equipment. It is widely used in applications requiring distributed I/O in assembly lines, packaging, machine tending, and other automated processes.

Key Features

-

Remote expansion of robot controller I/O ports

-

Supports digital and analog input/output signals

-

Fast and reliable communication with ABB robot controllers

-

Compact and rugged design suitable for industrial environments

-

Modular architecture allows easy scalability

-

Compatible with IRC5 and earlier ABB robot controllers

-

Supports various industrial communication protocols

-

LED indicators for diagnostics and status monitoring

-

Simplifies wiring and installation in complex automation setups

Technical Specifications

| Specification | Details |

|---|---|

| Product Name | Robot Remote I/O Module |

| Model Number | DSQC239 (YB560103-CH) |

| I/O Type | Digital and analog inputs/outputs |

| Number of I/O Channels | Typically configurable (varies by module version) |

| Communication Interface | ABB proprietary protocols, Ethernet (depending on system) |

| Operating Voltage | 24 V DC (standard industrial control voltage) |

| Operating Temperature Range | 0°C to 55°C |

| Storage Temperature Range | -20°C to 70°C |

| Humidity | 5% to 95% non-condensing |

| Dimensions | 200 x 120 x 60mm |

| Weight | 2.5 kg |

| Mounting | DIN rail or panel mounting |

| Status Indicators | LEDs for power, communication, and I/O status |

| Certifications | CE, UL, RoHS compliant |

| Environmental Protection | Designed for industrial use; IP rating varies by enclosure |

Industry Applications

The DSQC239 Robot Remote I/O Module is used extensively across industrial automation sectors, including:

Automotive manufacturing: Distributed control of sensors and actuators on robotic assembly lines

Electronics: Integration of inspection and testing devices

Food & Beverage: Remote control of packaging machinery I/O

Pharmaceuticals: Coordinating peripheral equipment in sterile environments

Metal fabrication: Controlling tooling and safety devices in welding and cutting applications

General manufacturing: Expanding I/O capability for complex machine tending and material handling robots

Product Advantages

Flexible I/O expansion: Easily increases the number of available input and output channels

Modular and scalable: Supports growth in automation complexity without redesigning control systems

Reliable and fast communication: Maintains synchronization between robot and peripheral devices

Industrial-grade construction: Designed to withstand factory conditions and electrical noise

Easy diagnostics: LED indicators simplify troubleshooting and maintenance

Simplified installation: Reduces wiring complexity and saves installation time

Compatibility with ABB controllers: Ensures seamless integration within ABB robotic systems

Supports multiple signal types: Digital and analog I/O flexibility enhances application range

Frequently Asked Questions (FAQ)

1. What is the purpose of the DSQC239 module?

It expands the input/output capability of ABB robot controllers by providing remote I/O channels.

2. Which ABB robot controllers are compatible?

It supports IRC5 and earlier ABB robot controllers.

3. How many I/O channels does it support?

The number of channels depends on the specific module configuration but typically includes multiple digital and analog inputs and outputs.

4. What communication protocols does it use?

It supports ABB proprietary communication protocols and Ethernet, depending on system configuration.

5. Can it be mounted in standard control cabinets?

Yes, it supports DIN rail or panel mounting for flexible installation.

6. What is the operating temperature range?

The module operates between 0°C and 55°C.

7. Does the module provide status indication?

Yes, LED indicators display power, communication, and I/O status.

8. Is it suitable for harsh industrial environments?

Yes, it is designed for industrial use with robust construction.

9. Can it handle both digital and analog signals?

Yes, it supports a range of digital and analog inputs and outputs.

10. How does this module simplify automation system design?

By providing remote I/O expansion, it reduces wiring complexity and enables distributed control architectures.

ABB DSQC239 YB560103-CH Robot Remote I/O Module

Manufacturer:ABB

Product Number:DSQC239 YB560103-CH

Product Type:Robot Remote I/O Module

Origin:Sweden

Dimensions:200 x 120 x 60mm

Weight:2.5kg

Views:40

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB DSQC239 (YB560103-CH) is a versatile Robot Remote I/O Module designed to expand the input/output capabilities of ABB robot controllers. This module enables seamless integration of additional sensors, actuators, and peripheral devices into the robot control system, allowing for enhanced automation flexibility and improved process control.

Engineered for industrial environments, the DSQC239 supports fast, reliable communication with the main controller, facilitating real-time data exchange and synchronized operation of robotic and peripheral equipment. It is widely used in applications requiring distributed I/O in assembly lines, packaging, machine tending, and other automated processes.

Key Features

-

Remote expansion of robot controller I/O ports

-

Supports digital and analog input/output signals

-

Fast and reliable communication with ABB robot controllers

-

Compact and rugged design suitable for industrial environments

-

Modular architecture allows easy scalability

-

Compatible with IRC5 and earlier ABB robot controllers

-

Supports various industrial communication protocols

-

LED indicators for diagnostics and status monitoring

-

Simplifies wiring and installation in complex automation setups

Technical Specifications

| Specification | Details |

|---|---|

| Product Name | Robot Remote I/O Module |

| Model Number | DSQC239 (YB560103-CH) |

| I/O Type | Digital and analog inputs/outputs |

| Number of I/O Channels | Typically configurable (varies by module version) |

| Communication Interface | ABB proprietary protocols, Ethernet (depending on system) |

| Operating Voltage | 24 V DC (standard industrial control voltage) |

| Operating Temperature Range | 0°C to 55°C |

| Storage Temperature Range | -20°C to 70°C |

| Humidity | 5% to 95% non-condensing |

| Dimensions | 200 x 120 x 60mm |

| Weight | 2.5 kg |

| Mounting | DIN rail or panel mounting |

| Status Indicators | LEDs for power, communication, and I/O status |

| Certifications | CE, UL, RoHS compliant |

| Environmental Protection | Designed for industrial use; IP rating varies by enclosure |

Industry Applications

The DSQC239 Robot Remote I/O Module is used extensively across industrial automation sectors, including:

Automotive manufacturing: Distributed control of sensors and actuators on robotic assembly lines

Electronics: Integration of inspection and testing devices

Food & Beverage: Remote control of packaging machinery I/O

Pharmaceuticals: Coordinating peripheral equipment in sterile environments

Metal fabrication: Controlling tooling and safety devices in welding and cutting applications

General manufacturing: Expanding I/O capability for complex machine tending and material handling robots

Product Advantages

Flexible I/O expansion: Easily increases the number of available input and output channels

Modular and scalable: Supports growth in automation complexity without redesigning control systems

Reliable and fast communication: Maintains synchronization between robot and peripheral devices

Industrial-grade construction: Designed to withstand factory conditions and electrical noise

Easy diagnostics: LED indicators simplify troubleshooting and maintenance

Simplified installation: Reduces wiring complexity and saves installation time

Compatibility with ABB controllers: Ensures seamless integration within ABB robotic systems

Supports multiple signal types: Digital and analog I/O flexibility enhances application range

Frequently Asked Questions (FAQ)

1. What is the purpose of the DSQC239 module?

It expands the input/output capability of ABB robot controllers by providing remote I/O channels.

2. Which ABB robot controllers are compatible?

It supports IRC5 and earlier ABB robot controllers.

3. How many I/O channels does it support?

The number of channels depends on the specific module configuration but typically includes multiple digital and analog inputs and outputs.

4. What communication protocols does it use?

It supports ABB proprietary communication protocols and Ethernet, depending on system configuration.

5. Can it be mounted in standard control cabinets?

Yes, it supports DIN rail or panel mounting for flexible installation.

6. What is the operating temperature range?

The module operates between 0°C and 55°C.

7. Does the module provide status indication?

Yes, LED indicators display power, communication, and I/O status.

8. Is it suitable for harsh industrial environments?

Yes, it is designed for industrial use with robust construction.

9. Can it handle both digital and analog signals?

Yes, it supports a range of digital and analog inputs and outputs.

10. How does this module simplify automation system design?

By providing remote I/O expansion, it reduces wiring complexity and enables distributed control architectures.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...