Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

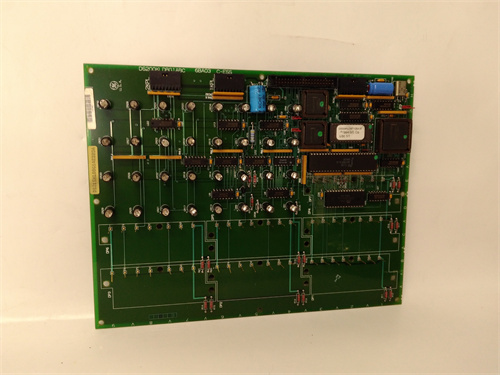

General Electric IS200AEPGG1A AEPG Board Assembly

Manufacturer:GE

Product Number:IS200AEPGG1A

Product Type:AEPG Board Assembly

Origin:USA

Dimensions:40 × 120 × 180 mm

Weight:0.25 kg

Views:99

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200AEPGG1A AEPG Board Assembly is an advanced control board used in GE Mark VI and Mark VIe turbine control systems. It is engineered to provide precise signal conditioning, power distribution, and communication functions for critical turbine and generator operations.

With its robust PCB design and high-quality electronic components, the AEPG Board Assembly ensures stable performance in high-temperature and high-vibration industrial environments. It plays a key role in maintaining reliable turbine control by managing analog and digital signals, supporting fault diagnostics, and enabling seamless integration with the larger GE control architecture.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS200AEPGG1A |

| Product Type | AEPG Board Assembly |

| Compatible System | GE Mark VI / Mark VIe turbine control systems |

| Function | Analog input processing, power distribution, and communication interface |

| Input Voltage | 24 VDC nominal |

| Communication Interfaces | High-speed backplane connector and diagnostic interface |

| Operating Temperature | 0 °C to 60 °C |

| Storage Temperature | –20 °C to 70 °C |

| Humidity Range | 5% to 95% non-condensing |

| Mounting Style | Rack or panel mount within Mark VI chassis |

| PCB Layers | Multi-layer, high-density design |

| Dimensions (W × H × D) | 40 × 120 × 180 mm |

| Weight | 0.25 kg |

Applications

Gas and Steam Turbine Control – Ensures precise signal conditioning and data exchange for generator and turbine operations.

Power Generation Plants – Integrates with Mark VI/VIe systems to monitor and control power plant equipment.

Industrial Process Control – Supports large-scale industrial automation where high reliability and quick response are critical.

Oil & Gas Facilities – Provides dependable control for compressors, pumps, and turbine-driven equipment.

Combined-Cycle Plants – Maintains synchronization and efficient control across multiple energy sources.

Retrofit Projects – Serves as a replacement or upgrade board in existing GE turbine control installations.

Advantages

High Reliability – Designed for continuous operation in demanding environments with strong resistance to vibration and electrical noise.

Precise Signal Processing – Offers accurate analog and digital signal conditioning for critical turbine measurements.

Seamless System Integration – Fully compatible with GE Mark VI/VIe control systems for simplified installation and commissioning.

Robust Diagnostics – Provides real-time feedback and fault detection to reduce downtime and maintenance costs.

Compact Design – Slim profile allows efficient use of panel or rack space.

Industrial Durability – Multi-layer PCB and high-grade components ensure long operational life and minimal maintenance.

Enhanced Safety – Supports stable operation of high-value power generation assets.

Scalable Performance – Easily accommodates system expansions or upgrades within GE control environments.

FAQ

Which control systems are compatible with the IS200AEPGG1A board?

It is designed for GE Mark VI and Mark VIe turbine control systems.

What primary functions does the AEPG Board Assembly perform?

It manages analog input processing, power distribution, and communication with the control backplane.

What is the nominal operating voltage required?

The board operates at a nominal 24 VDC supplied through the system chassis.

What communication interfaces are available?

A high-speed backplane connector and dedicated diagnostic interface are provided.

Can it be mounted in both rack and panel configurations?

Yes, it is suitable for standard Mark VI chassis rack or panel mounting.

Does the board provide built-in diagnostic functions?

Yes, it includes integrated diagnostics for real-time monitoring and fault detection.

What is the supported humidity range for operation?

It can operate in 5% to 95% non-condensing humidity environments.

Is the module hot-swappable within the Mark VI system?

It supports controlled replacement when the system is in maintenance mode.

How does the board handle electrical noise in industrial settings?

Its multi-layer PCB and shielding provide excellent noise immunity.

Can it interface with third-party monitoring equipment?

Yes, through its diagnostic interface and system backplane connections.

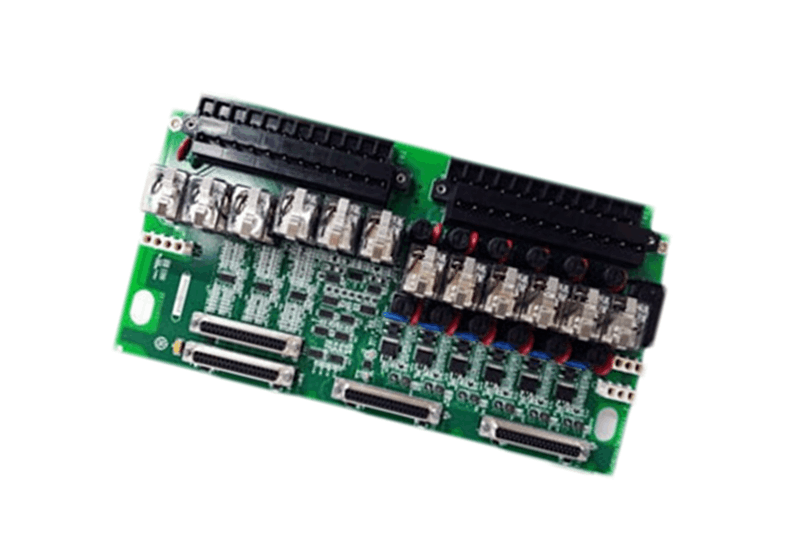

General Electric IS200AEPGG1A AEPG Board Assembly

Manufacturer:GE

Product Number:IS200AEPGG1A

Product Type:AEPG Board Assembly

Origin:USA

Dimensions:40 × 120 × 180 mm

Weight:0.25 kg

Views:99

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200AEPGG1A AEPG Board Assembly is an advanced control board used in GE Mark VI and Mark VIe turbine control systems. It is engineered to provide precise signal conditioning, power distribution, and communication functions for critical turbine and generator operations.

With its robust PCB design and high-quality electronic components, the AEPG Board Assembly ensures stable performance in high-temperature and high-vibration industrial environments. It plays a key role in maintaining reliable turbine control by managing analog and digital signals, supporting fault diagnostics, and enabling seamless integration with the larger GE control architecture.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS200AEPGG1A |

| Product Type | AEPG Board Assembly |

| Compatible System | GE Mark VI / Mark VIe turbine control systems |

| Function | Analog input processing, power distribution, and communication interface |

| Input Voltage | 24 VDC nominal |

| Communication Interfaces | High-speed backplane connector and diagnostic interface |

| Operating Temperature | 0 °C to 60 °C |

| Storage Temperature | –20 °C to 70 °C |

| Humidity Range | 5% to 95% non-condensing |

| Mounting Style | Rack or panel mount within Mark VI chassis |

| PCB Layers | Multi-layer, high-density design |

| Dimensions (W × H × D) | 40 × 120 × 180 mm |

| Weight | 0.25 kg |

Applications

Gas and Steam Turbine Control – Ensures precise signal conditioning and data exchange for generator and turbine operations.

Power Generation Plants – Integrates with Mark VI/VIe systems to monitor and control power plant equipment.

Industrial Process Control – Supports large-scale industrial automation where high reliability and quick response are critical.

Oil & Gas Facilities – Provides dependable control for compressors, pumps, and turbine-driven equipment.

Combined-Cycle Plants – Maintains synchronization and efficient control across multiple energy sources.

Retrofit Projects – Serves as a replacement or upgrade board in existing GE turbine control installations.

Advantages

High Reliability – Designed for continuous operation in demanding environments with strong resistance to vibration and electrical noise.

Precise Signal Processing – Offers accurate analog and digital signal conditioning for critical turbine measurements.

Seamless System Integration – Fully compatible with GE Mark VI/VIe control systems for simplified installation and commissioning.

Robust Diagnostics – Provides real-time feedback and fault detection to reduce downtime and maintenance costs.

Compact Design – Slim profile allows efficient use of panel or rack space.

Industrial Durability – Multi-layer PCB and high-grade components ensure long operational life and minimal maintenance.

Enhanced Safety – Supports stable operation of high-value power generation assets.

Scalable Performance – Easily accommodates system expansions or upgrades within GE control environments.

FAQ

Which control systems are compatible with the IS200AEPGG1A board?

It is designed for GE Mark VI and Mark VIe turbine control systems.

What primary functions does the AEPG Board Assembly perform?

It manages analog input processing, power distribution, and communication with the control backplane.

What is the nominal operating voltage required?

The board operates at a nominal 24 VDC supplied through the system chassis.

What communication interfaces are available?

A high-speed backplane connector and dedicated diagnostic interface are provided.

Can it be mounted in both rack and panel configurations?

Yes, it is suitable for standard Mark VI chassis rack or panel mounting.

Does the board provide built-in diagnostic functions?

Yes, it includes integrated diagnostics for real-time monitoring and fault detection.

What is the supported humidity range for operation?

It can operate in 5% to 95% non-condensing humidity environments.

Is the module hot-swappable within the Mark VI system?

It supports controlled replacement when the system is in maintenance mode.

How does the board handle electrical noise in industrial settings?

Its multi-layer PCB and shielding provide excellent noise immunity.

Can it interface with third-party monitoring equipment?

Yes, through its diagnostic interface and system backplane connections.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...