Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

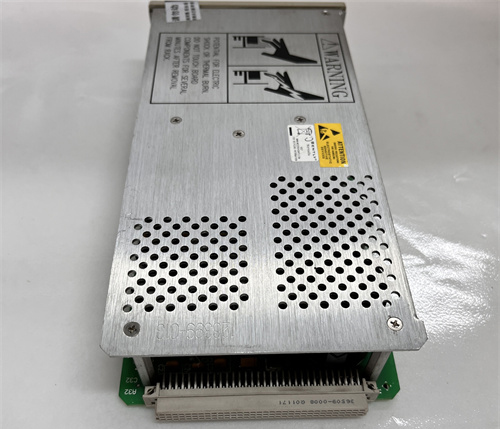

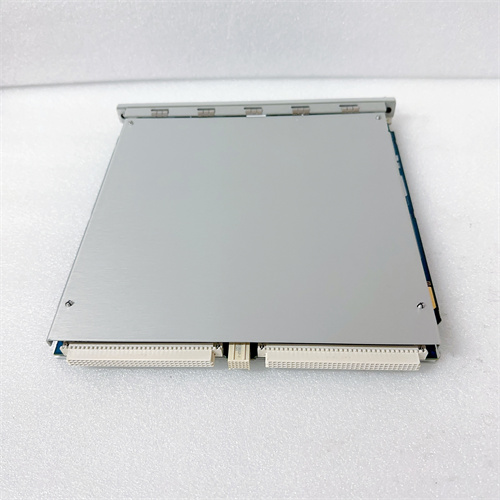

Bently Nevada 330130-045-13-00 3300 XL Standard Extension Cord

Manufacturer:Bently Nevada

Product Number:330130-045-13-00

Product Type:3300 XL Standard Extension Cord

Origin:USA

Cable length:4.5 m

Weight :0.464 kg

Views:29

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330130-045-13-00 is a high-performance vibration monitoring and protection system from the renowned Bently Nevada range of industrial equipment. It is designed for continuous monitoring of vibration levels in machinery such as turbines, motors, compressors, and other rotating equipment. This product is a part of the 3300 series, which offers high precision and robust performance in demanding industrial environments. Known for its reliability and ease of integration into existing systems, the 330130-045-13-00 is widely used in various sectors including energy, chemical, and manufacturing industries.

Its primary function is to detect and measure vibrations within machinery to predict potential failures before they happen, reducing downtime and maintenance costs. The system is capable of measuring a range of vibration parameters such as displacement, velocity, and acceleration, and offers the flexibility to operate in hazardous environments with high accuracy.

Technical Specifications

Below is the table that outlines the key technical specifications for the Bently Nevada 330130-045-13-00:

| Parameter | Specification |

|---|---|

| Model | 330130-045-13-00 |

| Type | Vibration Monitoring and Protection |

| Cable length | 4.5 m |

| Weight | 0.464 kg |

| Input Power | 24 VDC |

| Frequency Range | 0.1 Hz to 1 kHz |

| Output Signal | 4-20 mA, 0-10 VDC, or digital outputs |

| Environmental Operating Range | -40°C to 85°C |

| Mounting Type | DIN Rail or Panel Mount |

| Protection Class | IP65 |

| Certifications | CE, UL, Ex (Explosion Proof Options) |

Applications

The Bently Nevada 330130-045-13-00 is primarily used in applications where the continuous monitoring of rotating equipment is essential to prevent breakdowns and ensure operational efficiency. Some of the key applications include:

Power Generation – The device is widely used in power plants to monitor turbines, motors, and generators for signs of wear or imbalance, ensuring the equipment runs smoothly and preventing costly outages.

Oil and Gas – In the oil and gas industry, the product is used for compressors, pumps, and other critical machinery to maintain operational integrity and prevent downtime due to mechanical failures.

Manufacturing – The system is crucial for monitoring large industrial machines such as presses, conveyors, and mills to detect abnormal vibrations that could signal issues like misalignment or bearing failure.

Mining – It is used for monitoring mining equipment such as crushers, mills, and conveyors, where machinery is often subject to harsh operating conditions.

Marine – The product is utilized in marine applications for monitoring engines, turbines, and propulsion systems, ensuring safe operation and reducing the risk of equipment failure.

Advantages

The Bently Nevada 330130-045-13-00 offers a variety of benefits that make it a top choice for vibration monitoring:

Accurate Monitoring: The device provides high-precision vibration readings, ensuring that any potential failure can be detected well in advance.

Rugged Design: Built to withstand harsh industrial environments, it has an IP65 protection rating, making it dustproof and water-resistant.

Flexibility: It offers a wide range of outputs including 4-20 mA, 0-10 VDC, and digital signals, allowing easy integration into various control systems.

Ease of Use: The unit is easy to install and configure with clear diagnostics and user-friendly interface options.

Cost-Effective: By providing early warning signs of machinery failure, it helps prevent costly repairs and downtime, offering a return on investment over time.

Global Certifications: The product comes with various international certifications such as UL and CE, ensuring it meets global safety and quality standards.

FAQs

What kind of equipment can the 330130-045-13-00 monitor?

The product can monitor a wide variety of rotating machinery including turbines, compressors, pumps, and motors across different industrial sectors.

How does the vibration monitoring system work?

The system uses sensors to measure vibration levels of machinery and provides real-time data that can be used to identify any potential mechanical issues.

What is the maximum frequency range that the system can monitor?

The Bently Nevada 330130-045-13-00 has a frequency range from 0.1 Hz to 1 kHz, suitable for most industrial machinery.

Is the product suitable for hazardous environments?

Yes, it offers explosion-proof versions and has certifications like UL and Ex, making it suitable for hazardous areas.

How is the device powered?

The unit operates on a 24 VDC power supply.

Can the product be mounted in any environment?

The device is designed for industrial environments and can be mounted on DIN rails or in panels, with an IP65 protection class for dust and water resistance.

What types of outputs does the device offer?

It supports 4-20 mA, 0-10 VDC, and digital outputs for easy integration into different control systems.

Is there any software available for data analysis?

Yes, the data from the device can be integrated with Bently Nevada’s monitoring software for further analysis and reporting.

Can the product detect imbalances in rotating equipment?

Yes, the system is capable of detecting imbalance, misalignment, and other mechanical faults that cause abnormal vibrations.

What industries benefit most from this product?

Industries such as power generation, oil and gas, manufacturing, mining, and marine rely on the Bently Nevada 330130-045-13-00 for reliable vibration monitoring.

Bently Nevada 330130-045-13-00 3300 XL Standard Extension Cord

Manufacturer:Bently Nevada

Product Number:330130-045-13-00

Product Type:3300 XL Standard Extension Cord

Origin:USA

Cable length:4.5 m

Weight :0.464 kg

Views:29

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330130-045-13-00 is a high-performance vibration monitoring and protection system from the renowned Bently Nevada range of industrial equipment. It is designed for continuous monitoring of vibration levels in machinery such as turbines, motors, compressors, and other rotating equipment. This product is a part of the 3300 series, which offers high precision and robust performance in demanding industrial environments. Known for its reliability and ease of integration into existing systems, the 330130-045-13-00 is widely used in various sectors including energy, chemical, and manufacturing industries.

Its primary function is to detect and measure vibrations within machinery to predict potential failures before they happen, reducing downtime and maintenance costs. The system is capable of measuring a range of vibration parameters such as displacement, velocity, and acceleration, and offers the flexibility to operate in hazardous environments with high accuracy.

Technical Specifications

Below is the table that outlines the key technical specifications for the Bently Nevada 330130-045-13-00:

| Parameter | Specification |

|---|---|

| Model | 330130-045-13-00 |

| Type | Vibration Monitoring and Protection |

| Cable length | 4.5 m |

| Weight | 0.464 kg |

| Input Power | 24 VDC |

| Frequency Range | 0.1 Hz to 1 kHz |

| Output Signal | 4-20 mA, 0-10 VDC, or digital outputs |

| Environmental Operating Range | -40°C to 85°C |

| Mounting Type | DIN Rail or Panel Mount |

| Protection Class | IP65 |

| Certifications | CE, UL, Ex (Explosion Proof Options) |

Applications

The Bently Nevada 330130-045-13-00 is primarily used in applications where the continuous monitoring of rotating equipment is essential to prevent breakdowns and ensure operational efficiency. Some of the key applications include:

Power Generation – The device is widely used in power plants to monitor turbines, motors, and generators for signs of wear or imbalance, ensuring the equipment runs smoothly and preventing costly outages.

Oil and Gas – In the oil and gas industry, the product is used for compressors, pumps, and other critical machinery to maintain operational integrity and prevent downtime due to mechanical failures.

Manufacturing – The system is crucial for monitoring large industrial machines such as presses, conveyors, and mills to detect abnormal vibrations that could signal issues like misalignment or bearing failure.

Mining – It is used for monitoring mining equipment such as crushers, mills, and conveyors, where machinery is often subject to harsh operating conditions.

Marine – The product is utilized in marine applications for monitoring engines, turbines, and propulsion systems, ensuring safe operation and reducing the risk of equipment failure.

Advantages

The Bently Nevada 330130-045-13-00 offers a variety of benefits that make it a top choice for vibration monitoring:

Accurate Monitoring: The device provides high-precision vibration readings, ensuring that any potential failure can be detected well in advance.

Rugged Design: Built to withstand harsh industrial environments, it has an IP65 protection rating, making it dustproof and water-resistant.

Flexibility: It offers a wide range of outputs including 4-20 mA, 0-10 VDC, and digital signals, allowing easy integration into various control systems.

Ease of Use: The unit is easy to install and configure with clear diagnostics and user-friendly interface options.

Cost-Effective: By providing early warning signs of machinery failure, it helps prevent costly repairs and downtime, offering a return on investment over time.

Global Certifications: The product comes with various international certifications such as UL and CE, ensuring it meets global safety and quality standards.

FAQs

What kind of equipment can the 330130-045-13-00 monitor?

The product can monitor a wide variety of rotating machinery including turbines, compressors, pumps, and motors across different industrial sectors.

How does the vibration monitoring system work?

The system uses sensors to measure vibration levels of machinery and provides real-time data that can be used to identify any potential mechanical issues.

What is the maximum frequency range that the system can monitor?

The Bently Nevada 330130-045-13-00 has a frequency range from 0.1 Hz to 1 kHz, suitable for most industrial machinery.

Is the product suitable for hazardous environments?

Yes, it offers explosion-proof versions and has certifications like UL and Ex, making it suitable for hazardous areas.

How is the device powered?

The unit operates on a 24 VDC power supply.

Can the product be mounted in any environment?

The device is designed for industrial environments and can be mounted on DIN rails or in panels, with an IP65 protection class for dust and water resistance.

What types of outputs does the device offer?

It supports 4-20 mA, 0-10 VDC, and digital outputs for easy integration into different control systems.

Is there any software available for data analysis?

Yes, the data from the device can be integrated with Bently Nevada’s monitoring software for further analysis and reporting.

Can the product detect imbalances in rotating equipment?

Yes, the system is capable of detecting imbalance, misalignment, and other mechanical faults that cause abnormal vibrations.

What industries benefit most from this product?

Industries such as power generation, oil and gas, manufacturing, mining, and marine rely on the Bently Nevada 330130-045-13-00 for reliable vibration monitoring.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...