Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

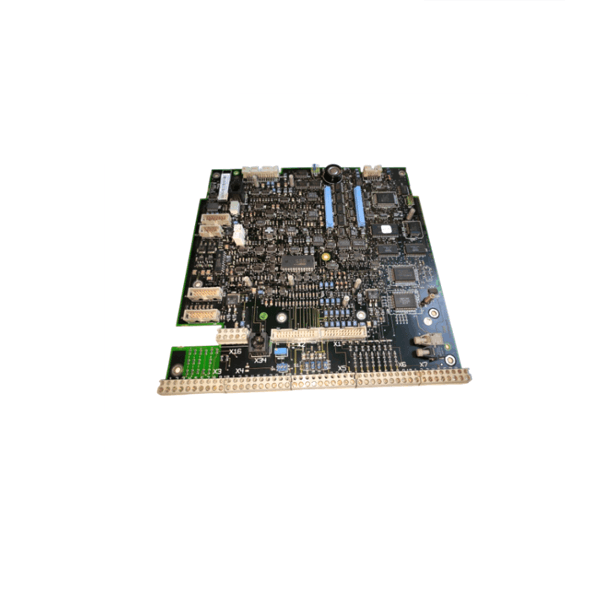

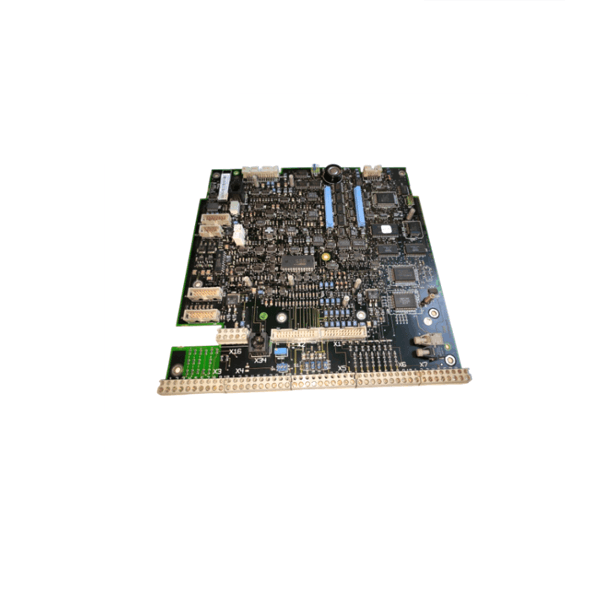

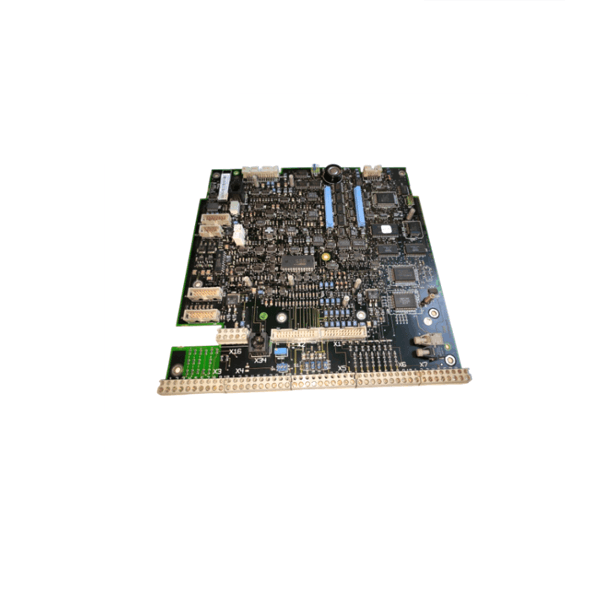

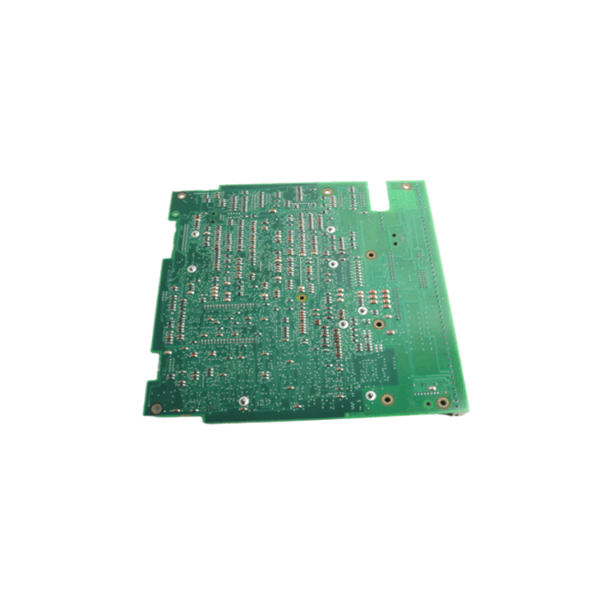

ABB SDCS-CON-2 3ADT309600R1 Control Panel

Manufacturer:ABB

Product Number:SDCS-CON-2 3ADT309600R1

Condition:Control Panel

Origin:Sweden

Dimensions:205 × 90 × 45 mm

Weight:0.113kg

Views:27

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

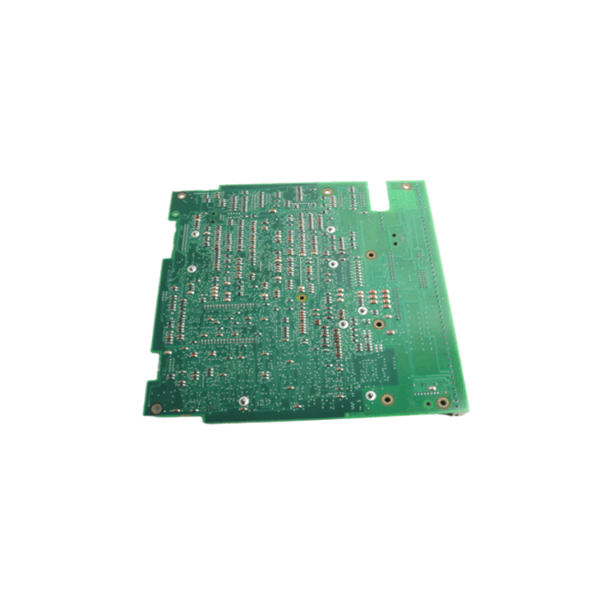

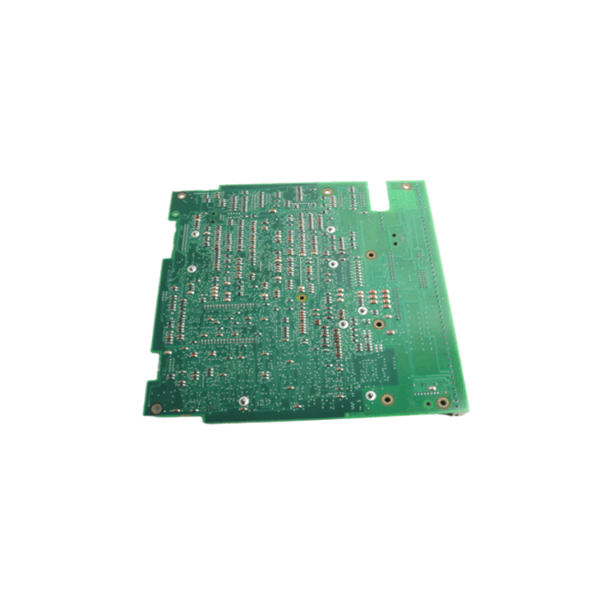

This controller board features robust construction, reliable connectivity options, and precise digital and analog interfacing to support demanding motion control and automation systems. It is specifically developed to provide high-speed, real-time control and feedback in power conversion and motor management setups.

Product Features and Advantages

High Integration Compatibility: Seamlessly integrates with ABB DCS500/600 drive systems for legacy and modern installations.

Robust Industrial Design: Engineered for high-reliability in harsh electrical and environmental conditions.

Flexible Communication: Supports a range of I/O configurations and communication protocols to match diverse application needs.

Precision Control: Enhances the precision of drive operations with fast signal processing and advanced diagnostics.

Field Proven: Trusted in steel mills, paper plants, mining, and transportation sectors worldwide.

Serviceable and Replaceable: Easy to replace and commission, reducing downtime during maintenance or upgrade.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | SDCS-CON-2 |

| ABB Part Number | 3ADT309600R1 |

| Product Type | Control Board for DC Drive |

| Series Compatibility | DCS500 / DCS600 Series Drives |

| Input Voltage (Control) | 24 VDC (typical via power board interface) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -25°C to +70°C |

| Relative Humidity | 5%–95% (non-condensing) |

| Mounting Method | Plug-in into drive chassis slot |

| Communication Interfaces | CAN, fiber optic link, RS232 (via expansion) |

| Status Indicators | LED diagnostics for I/O and status monitoring |

| Dimensions | 205 × 90 × 45 mm |

| Weight | 0.113kg |

| PCB Material | Industrial-grade FR4, conformally coated |

| Certifications | CE, RoHS compliant, industrial EMC standards |

Applications

The ABB SDCS-CON-2 controller board is widely used in industries that rely on high-performance DC drive control systems. Typical applications include:

Steel and Metal Processing Plants

Paper and Pulp Industry

Mining and Heavy Machinery Operations

Marine and Transportation Systems

Rolling Mills and Conveyors

Automated Production Lines

Its modular and serviceable design makes it ideal for both new installations and retrofitting existing ABB DC drive systems.

Installation Guidelines

Preparation: Ensure that all power sources to the drive are disconnected before installation.

Safety Precautions: Wear ESD protection when handling the board to avoid static damage.

Mounting: Align the SDCS-CON-2 with the designated control slot on the DCS500/600 drive chassis.

Connection: Insert the board carefully until fully seated; connect I/O and communication lines as per the wiring diagram.

Configuration: Use ABB’s drive configuration software or the HMI panel to load firmware and configure parameters.

Testing: Power on the drive and observe diagnostic LEDs. Perform commissioning tests and validate system control.

FAQs

Q1: What is the main function of the ABB SDCS-CON-2 board?

A1: It acts as the central control unit for ABB DCS500 and DCS600 DC drives, handling signal processing, communication, and drive control logic.

Q2: Can the SDCS-CON-2 be used in modern drive systems?

A2: Yes, although primarily designed for legacy DCS drives, it remains compatible with many current ABB systems that use the same control architecture.

Q3: How is the board installed into the drive?

A3: It plugs directly into the control slot on the drive chassis and interfaces with the power and signal components internally.

Q4: Does the board support communication over fiber optics?

A4: Yes, the board supports both CAN and fiber optic communications for high-speed signal transmission.

Q5: What happens if the control board fails?

A5: A failed control board typically disables the drive. However, replacement is straightforward, and diagnostics can be performed via LED indicators.

Q6: What kind of maintenance does it require?

A6: Minimal maintenance is needed, but periodic cleaning of the drive enclosure and visual inspection for damage is recommended.

Q7: Is this board CE-certified?

A7: Yes, it complies with CE directives and relevant industrial EMC standards.

Q8: Can this board be repaired if damaged?

A8: In most industrial settings, it’s recommended to replace the board rather than repair it due to its critical control function.

Q9: How long is the typical lifespan of the board?

A9: With proper usage, the board can operate effectively for 5+ years in controlled environments.

Q10: Is there a software tool required to configure this board?

A10: Yes, ABB provides configuration tools that allow for firmware updates, parameter setting, and diagnostics.

ABB SDCS-CON-2 3ADT309600R1 Control Panel

Manufacturer:ABB

Product Number:SDCS-CON-2 3ADT309600R1

Condition:Control Panel

Origin:Sweden

Dimensions:205 × 90 × 45 mm

Weight:0.113kg

Views:27

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

This controller board features robust construction, reliable connectivity options, and precise digital and analog interfacing to support demanding motion control and automation systems. It is specifically developed to provide high-speed, real-time control and feedback in power conversion and motor management setups.

Product Features and Advantages

High Integration Compatibility: Seamlessly integrates with ABB DCS500/600 drive systems for legacy and modern installations.

Robust Industrial Design: Engineered for high-reliability in harsh electrical and environmental conditions.

Flexible Communication: Supports a range of I/O configurations and communication protocols to match diverse application needs.

Precision Control: Enhances the precision of drive operations with fast signal processing and advanced diagnostics.

Field Proven: Trusted in steel mills, paper plants, mining, and transportation sectors worldwide.

Serviceable and Replaceable: Easy to replace and commission, reducing downtime during maintenance or upgrade.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | SDCS-CON-2 |

| ABB Part Number | 3ADT309600R1 |

| Product Type | Control Board for DC Drive |

| Series Compatibility | DCS500 / DCS600 Series Drives |

| Input Voltage (Control) | 24 VDC (typical via power board interface) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -25°C to +70°C |

| Relative Humidity | 5%–95% (non-condensing) |

| Mounting Method | Plug-in into drive chassis slot |

| Communication Interfaces | CAN, fiber optic link, RS232 (via expansion) |

| Status Indicators | LED diagnostics for I/O and status monitoring |

| Dimensions | 205 × 90 × 45 mm |

| Weight | 0.113kg |

| PCB Material | Industrial-grade FR4, conformally coated |

| Certifications | CE, RoHS compliant, industrial EMC standards |

Applications

The ABB SDCS-CON-2 controller board is widely used in industries that rely on high-performance DC drive control systems. Typical applications include:

Steel and Metal Processing Plants

Paper and Pulp Industry

Mining and Heavy Machinery Operations

Marine and Transportation Systems

Rolling Mills and Conveyors

Automated Production Lines

Its modular and serviceable design makes it ideal for both new installations and retrofitting existing ABB DC drive systems.

Installation Guidelines

Preparation: Ensure that all power sources to the drive are disconnected before installation.

Safety Precautions: Wear ESD protection when handling the board to avoid static damage.

Mounting: Align the SDCS-CON-2 with the designated control slot on the DCS500/600 drive chassis.

Connection: Insert the board carefully until fully seated; connect I/O and communication lines as per the wiring diagram.

Configuration: Use ABB’s drive configuration software or the HMI panel to load firmware and configure parameters.

Testing: Power on the drive and observe diagnostic LEDs. Perform commissioning tests and validate system control.

FAQs

Q1: What is the main function of the ABB SDCS-CON-2 board?

A1: It acts as the central control unit for ABB DCS500 and DCS600 DC drives, handling signal processing, communication, and drive control logic.

Q2: Can the SDCS-CON-2 be used in modern drive systems?

A2: Yes, although primarily designed for legacy DCS drives, it remains compatible with many current ABB systems that use the same control architecture.

Q3: How is the board installed into the drive?

A3: It plugs directly into the control slot on the drive chassis and interfaces with the power and signal components internally.

Q4: Does the board support communication over fiber optics?

A4: Yes, the board supports both CAN and fiber optic communications for high-speed signal transmission.

Q5: What happens if the control board fails?

A5: A failed control board typically disables the drive. However, replacement is straightforward, and diagnostics can be performed via LED indicators.

Q6: What kind of maintenance does it require?

A6: Minimal maintenance is needed, but periodic cleaning of the drive enclosure and visual inspection for damage is recommended.

Q7: Is this board CE-certified?

A7: Yes, it complies with CE directives and relevant industrial EMC standards.

Q8: Can this board be repaired if damaged?

A8: In most industrial settings, it’s recommended to replace the board rather than repair it due to its critical control function.

Q9: How long is the typical lifespan of the board?

A9: With proper usage, the board can operate effectively for 5+ years in controlled environments.

Q10: Is there a software tool required to configure this board?

A10: Yes, ABB provides configuration tools that allow for firmware updates, parameter setting, and diagnostics.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...