Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

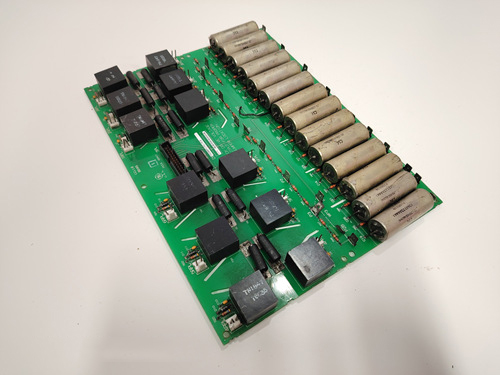

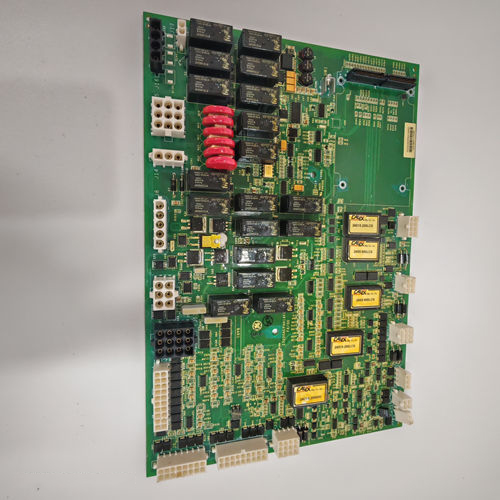

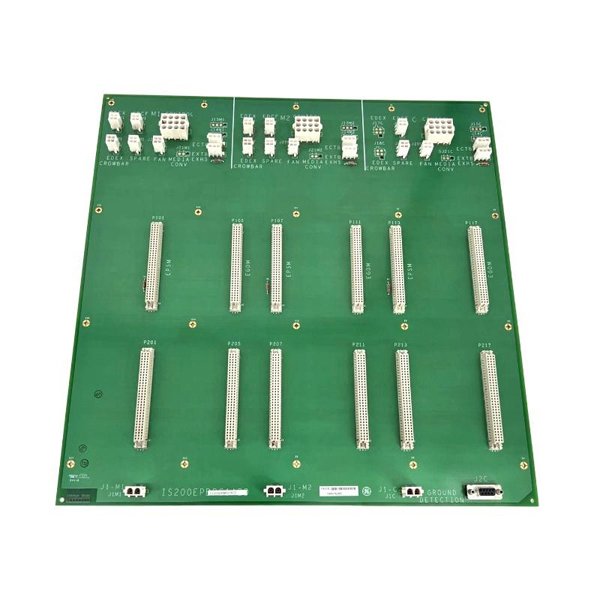

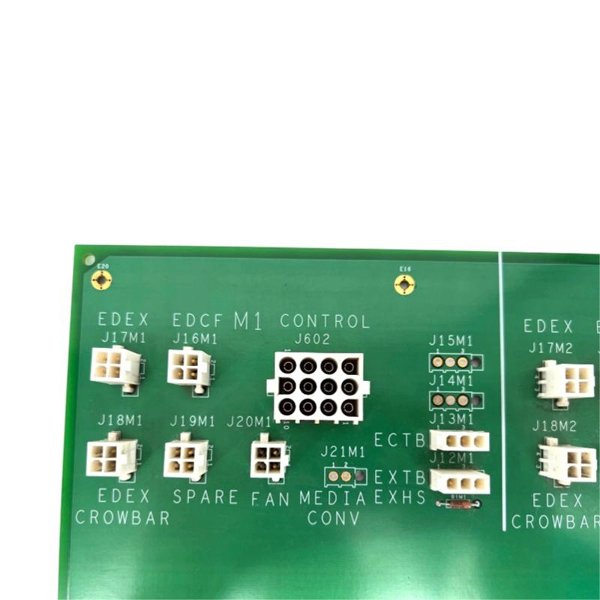

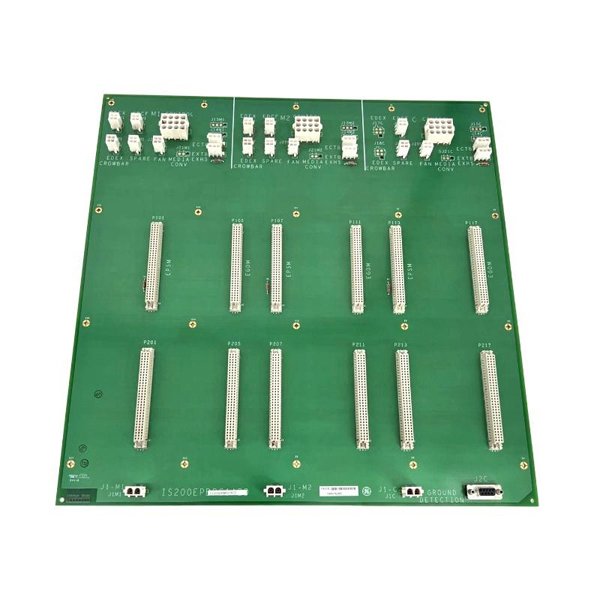

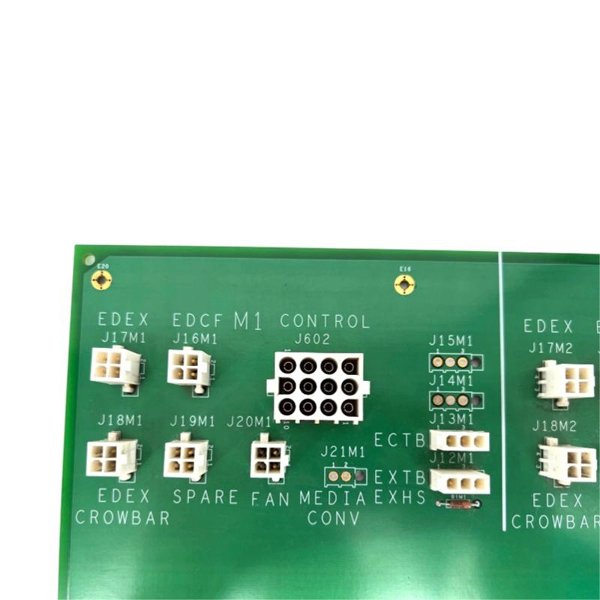

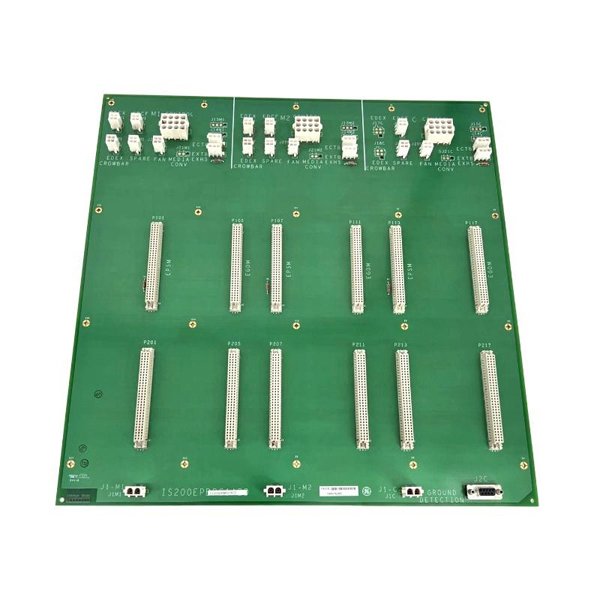

General Electric IS200EPBPG1A Exciter Power Backplane Board

Manufacturer:GE

Product Number:IS200EPBPG1A

Product Type:Exciter Power Backplane Board

Origin:USA

Dimensions:330 × 260 × 40 mm

Weight:0.5 kg

Views:26

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

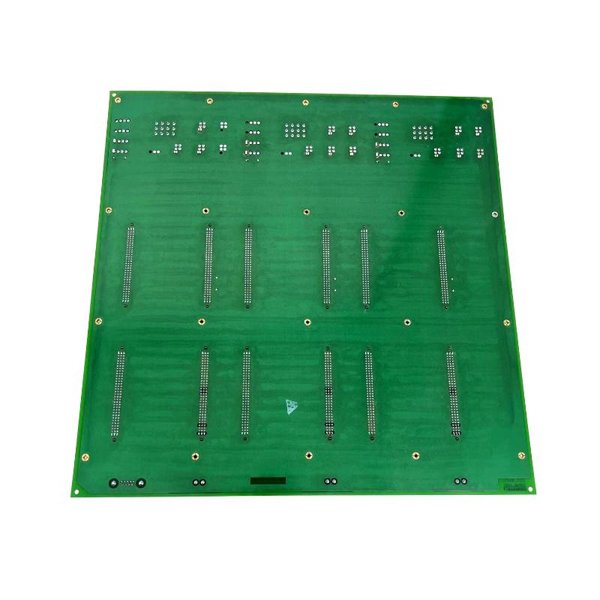

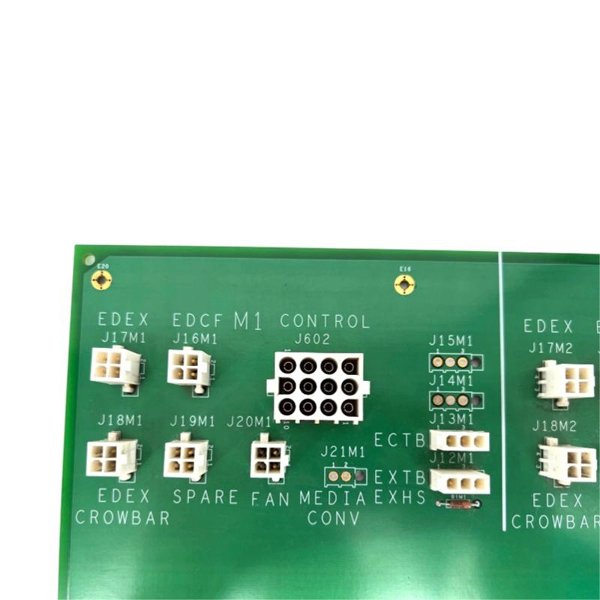

The GE IS200EPBPG1A is an industrial-grade Exciter Power Backplane Board engineered to function within the Mark VI and Mark VIe excitation control systems developed by General Electric (GE). This backplane board serves as the central electrical and mechanical connection interface for exciter power components. It provides stable mounting and efficient power distribution to multiple plug-in modules used in the excitation system, particularly in synchronous generator applications.

The IS200EPBPG1A is a critical element in the power section of the exciter control cabinet. It acts as a bus system that facilitates communication and power sharing between boards such as power converters, control processors, and I/O interfaces. This modular backplane design enhances flexibility, allowing for the swift replacement or addition of exciter control components without the need to rewire the entire system.

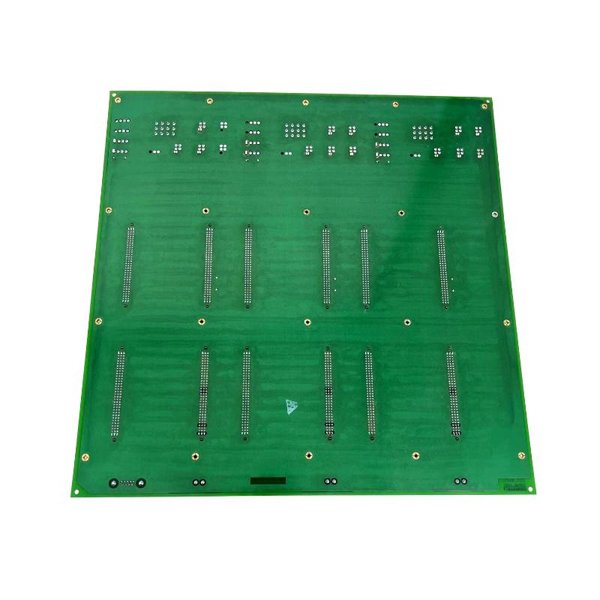

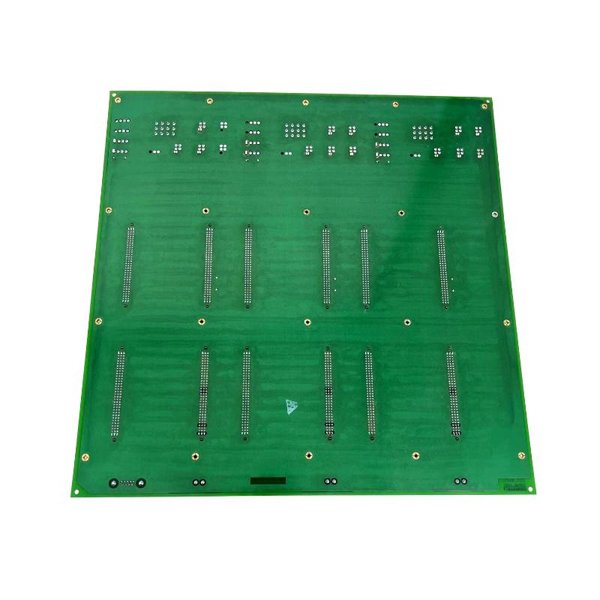

Built with high-reliability connectors and rugged materials, this board is designed to endure harsh environmental conditions, such as those found in power generation facilities, including thermal cycling, high humidity, and electrical noise. Its high current-carrying capacity and efficient heat dissipation further ensure long-term performance and system integrity.

Technical Specifications

| Specification | Details |

|---|---|

| Model Number | IS200EPBPG1A |

| Manufacturer | General Electric (GE) |

| Product Type | Exciter Power Backplane Board |

| System Compatibility | GE Mark VI / VIe Excitation Systems |

| Function | Power distribution and module connectivity |

| Mounting Type | Rack-mounted, screw-secured |

| Connector Type | High-density backplane connectors (male/female) |

| Voltage Handling | Up to 600 VDC (internal circuits) |

| Current Handling | Up to 50 Amps (per power rail) |

| Cooling Method | Convection (requires cabinet ventilation) |

| Protective Coating | Conformal coating against humidity and dust |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C (-40°F to 185°F) |

| Humidity Range | 5%–95% RH, non-condensing |

| Shock Resistance | 15 g peak (per IEC 60068-2-27) |

| Vibration Tolerance | 2 g, 10–500 Hz (per IEC 60068-2-6) |

| Dimensions (L×W×H) | 330 × 260 × 40 mm |

| Weight | 0.5 kg |

| Compliance | RoHS, UL Recognized, CE Marked |

Product Applications

The IS200EPBPG1A serves in a wide range of power generation applications where precision, stability, and reliability are critical. It is most commonly found in:

Synchronous Generator Excitation Systems

Provides robust connectivity and reliable power distribution between exciter modules.

Turbine Control Cabinets

Acts as a centralized platform for connecting power converter and control boards within turbine generator control enclosures.

Utility Power Plants

Deployed in excitation systems that support steam, gas, and hydro turbine generators in large-scale utilities.

Industrial Power Systems

Used in heavy industry where in-house power generation and voltage regulation are necessary, such as oil & gas, cement, and pulp & paper industries.

Retrofit Projects

Ideal for replacing aging exciter backplane components in legacy GE control systems with minimal reconfiguration.

Product Advantages

Centralized Power Integration

Enables streamlined connection of exciter modules with reduced cabling and maximum reliability.

Rugged Industrial Design

Built to handle high electrical loads and withstand harsh environmental conditions over long operating cycles.

Modular Architecture

Facilitates fast module swaps and simplifies maintenance in field applications.

High Compatibility

Designed to support a variety of plug-in boards and modules used in the Mark VI and VIe exciter systems.

Enhanced System Protection

Includes power bus fusing and short-circuit protection features that safeguard sensitive exciter components.

Efficient Layout

Optimized for cabinet space utilization while providing thermal airflow pathways to prevent overheating.

Reduced Downtime

Supports quick fault isolation and field repair, minimizing disruptions in generator operations.

Certified Compliance

Meets industry standards for electrical safety, electromagnetic compatibility, and environmental performance.

Frequently Asked Questions (FAQ)

1. What is the main function of the IS200EPBPG1A board?

It serves as a backplane that connects and distributes power among exciter modules in a GE excitation system.

2. Can this board be used in non-GE systems?

It is specifically designed for GE Mark VI and Mark VIe systems; compatibility with non-GE systems is not recommended.

3. How many modules can connect to this backplane?

Typically, it supports up to 5 or more exciter modules, depending on the configuration of the system.

4. Does the board require active cooling?

No active cooling is built-in; however, cabinet ventilation is necessary for optimal performance.

5. What is the voltage and current capacity of the board?

It can handle up to 600 VDC and 50 Amps per rail.

6. Is the IS200EPBPG1A conformal coated?

Yes, it includes conformal coating for protection against moisture, dust, and corrosive gases.

7. What mounting options does the board support?

It is rack-mounted and securely fastened using screws to maintain electrical and mechanical stability.

8. How is it connected to other exciter boards?

It uses specialized high-density connectors to interface with exciter power and control modules.

9. Is this board field-replaceable?

Yes, it is designed for field replacement during system upgrades or maintenance.

10. What is the board’s expected service life?

With proper conditions, the board can function reliably for over 10 years in industrial environments.

General Electric IS200EPBPG1A Exciter Power Backplane Board

Manufacturer:GE

Product Number:IS200EPBPG1A

Product Type:Exciter Power Backplane Board

Origin:USA

Dimensions:330 × 260 × 40 mm

Weight:0.5 kg

Views:26

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200EPBPG1A is an industrial-grade Exciter Power Backplane Board engineered to function within the Mark VI and Mark VIe excitation control systems developed by General Electric (GE). This backplane board serves as the central electrical and mechanical connection interface for exciter power components. It provides stable mounting and efficient power distribution to multiple plug-in modules used in the excitation system, particularly in synchronous generator applications.

The IS200EPBPG1A is a critical element in the power section of the exciter control cabinet. It acts as a bus system that facilitates communication and power sharing between boards such as power converters, control processors, and I/O interfaces. This modular backplane design enhances flexibility, allowing for the swift replacement or addition of exciter control components without the need to rewire the entire system.

Built with high-reliability connectors and rugged materials, this board is designed to endure harsh environmental conditions, such as those found in power generation facilities, including thermal cycling, high humidity, and electrical noise. Its high current-carrying capacity and efficient heat dissipation further ensure long-term performance and system integrity.

Technical Specifications

| Specification | Details |

|---|---|

| Model Number | IS200EPBPG1A |

| Manufacturer | General Electric (GE) |

| Product Type | Exciter Power Backplane Board |

| System Compatibility | GE Mark VI / VIe Excitation Systems |

| Function | Power distribution and module connectivity |

| Mounting Type | Rack-mounted, screw-secured |

| Connector Type | High-density backplane connectors (male/female) |

| Voltage Handling | Up to 600 VDC (internal circuits) |

| Current Handling | Up to 50 Amps (per power rail) |

| Cooling Method | Convection (requires cabinet ventilation) |

| Protective Coating | Conformal coating against humidity and dust |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C (-40°F to 185°F) |

| Humidity Range | 5%–95% RH, non-condensing |

| Shock Resistance | 15 g peak (per IEC 60068-2-27) |

| Vibration Tolerance | 2 g, 10–500 Hz (per IEC 60068-2-6) |

| Dimensions (L×W×H) | 330 × 260 × 40 mm |

| Weight | 0.5 kg |

| Compliance | RoHS, UL Recognized, CE Marked |

Product Applications

The IS200EPBPG1A serves in a wide range of power generation applications where precision, stability, and reliability are critical. It is most commonly found in:

Synchronous Generator Excitation Systems

Provides robust connectivity and reliable power distribution between exciter modules.

Turbine Control Cabinets

Acts as a centralized platform for connecting power converter and control boards within turbine generator control enclosures.

Utility Power Plants

Deployed in excitation systems that support steam, gas, and hydro turbine generators in large-scale utilities.

Industrial Power Systems

Used in heavy industry where in-house power generation and voltage regulation are necessary, such as oil & gas, cement, and pulp & paper industries.

Retrofit Projects

Ideal for replacing aging exciter backplane components in legacy GE control systems with minimal reconfiguration.

Product Advantages

Centralized Power Integration

Enables streamlined connection of exciter modules with reduced cabling and maximum reliability.

Rugged Industrial Design

Built to handle high electrical loads and withstand harsh environmental conditions over long operating cycles.

Modular Architecture

Facilitates fast module swaps and simplifies maintenance in field applications.

High Compatibility

Designed to support a variety of plug-in boards and modules used in the Mark VI and VIe exciter systems.

Enhanced System Protection

Includes power bus fusing and short-circuit protection features that safeguard sensitive exciter components.

Efficient Layout

Optimized for cabinet space utilization while providing thermal airflow pathways to prevent overheating.

Reduced Downtime

Supports quick fault isolation and field repair, minimizing disruptions in generator operations.

Certified Compliance

Meets industry standards for electrical safety, electromagnetic compatibility, and environmental performance.

Frequently Asked Questions (FAQ)

1. What is the main function of the IS200EPBPG1A board?

It serves as a backplane that connects and distributes power among exciter modules in a GE excitation system.

2. Can this board be used in non-GE systems?

It is specifically designed for GE Mark VI and Mark VIe systems; compatibility with non-GE systems is not recommended.

3. How many modules can connect to this backplane?

Typically, it supports up to 5 or more exciter modules, depending on the configuration of the system.

4. Does the board require active cooling?

No active cooling is built-in; however, cabinet ventilation is necessary for optimal performance.

5. What is the voltage and current capacity of the board?

It can handle up to 600 VDC and 50 Amps per rail.

6. Is the IS200EPBPG1A conformal coated?

Yes, it includes conformal coating for protection against moisture, dust, and corrosive gases.

7. What mounting options does the board support?

It is rack-mounted and securely fastened using screws to maintain electrical and mechanical stability.

8. How is it connected to other exciter boards?

It uses specialized high-density connectors to interface with exciter power and control modules.

9. Is this board field-replaceable?

Yes, it is designed for field replacement during system upgrades or maintenance.

10. What is the board’s expected service life?

With proper conditions, the board can function reliably for over 10 years in industrial environments.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...