Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

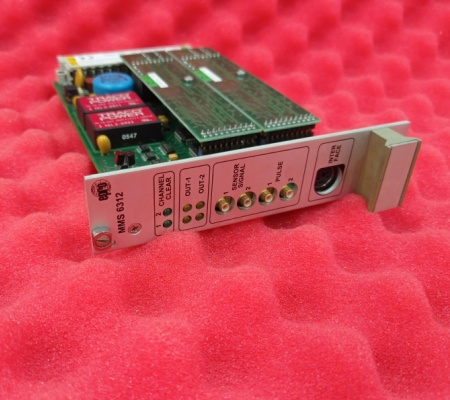

Epro MMS 6312 Dual Channel Rotational Speed Monitor

Manufacture :EPRO

Item No :MMS 6312

Article number :MMS 6312

Series :MMS6000

Origin :Germany (DE)

Dimension :85*11*120(mm)

Weight :0.8 kg

Customs Tariff Number :85389091

Product Description

The dual channel speed measurement module MMS6312 measures shaft speed - using the output of a pulse sensor combined with a trigger wheel. The two channels can be used individually to measure:

- 2 speeds from 2 axes

- 2 stationary points on both axes

- 2 key pulses from both axes, each with a trigger mark (with phase relationship)

The two channels can also be used to communicate with each other:

-Detect the direction of rotation of a shaft

-Detect the difference between the speeds of two shafts

-As part of a multi-channel or redundant system

Requirements for analytical and diagnostic systems, fieldbus systems, distributed control systems, plant/host computers, and networks (e.g., WAN/LAN, Ethernet). Such systems are also suitable for building systems to improve performance and efficiency, operational safety, and extend the service life of machines such as steam-gas-water turbines and compressors, fans, centrifuges, and other turbines.

-Part of the MMS 6000 system

-Replaceable during operation; can be used independently, redundant power supply input

-Extended self-checking facilities; built-in sensor self-testing facilities

-Suitable for use with eddy current transducer systems PR6422/. to PR 6425/... with CON0 or with pulse sensors PR9376/... and PR6453/...

-Galvanic separation current output

-RS 232 interface for local configuration and readout

-RS485 interface for communication with the epro analysis and diagnostic system MMS6850

PCB/EURO card format acc. to DIN 41494 (100 x 160 mm)

Width: 30,0 mm (6 TE)

Height: 128,4 mm (3 HE)

Length: 160,0 mm

Net weight: app. 320 g

Gross weight: app. 450 g

incl. standard export packing

Packing volume: app. 2,5 dm3

Space requirements:

14 modules (28 channels) fit into each

19“ rack

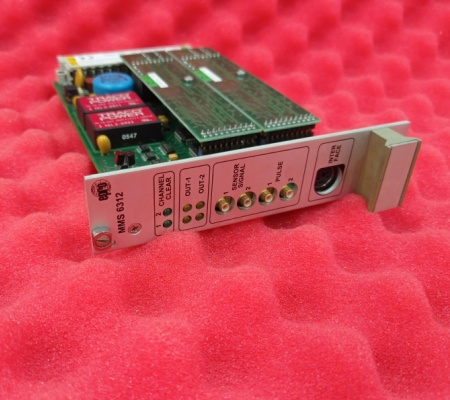

Epro MMS 6312 Dual Channel Rotational Speed Monitor

Manufacture :EPRO

Item No :MMS 6312

Article number :MMS 6312

Series :MMS6000

Origin :Germany (DE)

Dimension :85*11*120(mm)

Weight :0.8 kg

Customs Tariff Number :85389091

Product Description

The dual channel speed measurement module MMS6312 measures shaft speed - using the output of a pulse sensor combined with a trigger wheel. The two channels can be used individually to measure:

- 2 speeds from 2 axes

- 2 stationary points on both axes

- 2 key pulses from both axes, each with a trigger mark (with phase relationship)

The two channels can also be used to communicate with each other:

-Detect the direction of rotation of a shaft

-Detect the difference between the speeds of two shafts

-As part of a multi-channel or redundant system

Requirements for analytical and diagnostic systems, fieldbus systems, distributed control systems, plant/host computers, and networks (e.g., WAN/LAN, Ethernet). Such systems are also suitable for building systems to improve performance and efficiency, operational safety, and extend the service life of machines such as steam-gas-water turbines and compressors, fans, centrifuges, and other turbines.

-Part of the MMS 6000 system

-Replaceable during operation; can be used independently, redundant power supply input

-Extended self-checking facilities; built-in sensor self-testing facilities

-Suitable for use with eddy current transducer systems PR6422/. to PR 6425/... with CON0 or with pulse sensors PR9376/... and PR6453/...

-Galvanic separation current output

-RS 232 interface for local configuration and readout

-RS485 interface for communication with the epro analysis and diagnostic system MMS6850

PCB/EURO card format acc. to DIN 41494 (100 x 160 mm)

Width: 30,0 mm (6 TE)

Height: 128,4 mm (3 HE)

Length: 160,0 mm

Net weight: app. 320 g

Gross weight: app. 450 g

incl. standard export packing

Packing volume: app. 2,5 dm3

Space requirements:

14 modules (28 channels) fit into each

19“ rack

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...