Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

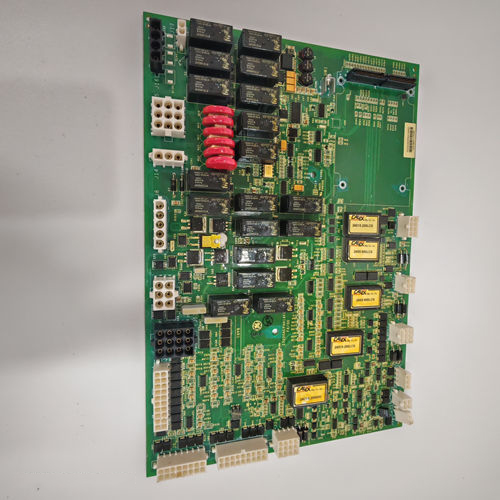

General Electric IS215UCVEH2A VME Control Card

Manufacturer:GE

Product Number:IS215UCVEH2A

Product Type:VME Control Card

Origin:USA

Dimensions:82.6 x 41.9 mm

Weight:0.907 kg

Views:60

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

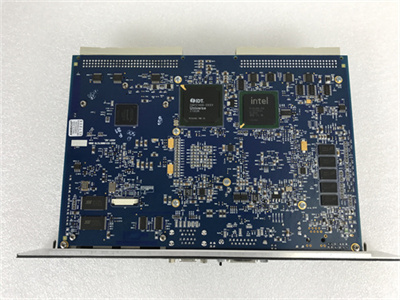

The GE IS215UCVEH2A VME Control Card is a pivotal component within General Electric’s Mark VI Series, specifically designed to manage and control industrial gas and steam turbines. Functioning as a high-performance processor, this controller card efficiently handles complex control tasks, ensuring optimal performance and reliability in demanding industrial environments.

Product Specifications

| Specification | Details |

|---|---|

| Processor | 300 MHz Intel Celeron |

| Memory | 16 MB or 128 MB Flash Memory; 32 MB DRAM |

| Ethernet | 10BaseT/100BaseTX (RJ-45) |

| Dimensions | 82.6 x 41.9 mm |

| Weight | 0.907 kg |

| Operating Temperature | -30°C to +65°C |

| Power Requirements | +5 V DC (6 A typical, 8 A max); +12 V DC (180 mA typical, 250 mA max); -12 V DC (180 mA typical, 250 mA max) |

Applications

The IS215UCVEH2A is integral to GE’s Speedtronic Mark VI control systems, primarily deployed in:

Gas and Steam Turbine Control: Ensures precise operation and monitoring of turbine systems in power generation plants.

Industrial Automation: Manages complex processes in manufacturing and other industrial settings requiring reliable control solutions.

Advantages

High Performance: Equipped with a robust 300 MHz Intel Celeron processor, it adeptly handles intricate control tasks.

Versatile Memory Options: Offers flexibility with 16 MB or 128 MB Flash Memory configurations, complemented by 32 MB DRAM for efficient data processing.

Seamless Integration: Designed to integrate smoothly within VME-based backplane systems, facilitating robust communication and data transfer.

Frequently Asked Questions (FAQ)

What role does the IS215UCVEH2A play in turbine control systems?

- It functions as the central processing unit, executing control algorithms to manage turbine operations effectively.

Is the IS215UCVEH2A compatible with other GE control systems?

- Yes, it is designed for seamless integration within GE’s Mark VI Series control systems.

What types of memory are utilized in this control card?

- It features 16 MB or 128 MB of Flash Memory and 32 MB of DRAM.

What are the power requirements for the IS215UCVEH2A?

- It requires +5 V DC (6 A typical, 8 A max), +12 V DC (180 mA typical, 250 mA max), and -12 V DC (180 mA typical, 250 mA max).

Can this control card operate in harsh environmental conditions?

- Yes, it is designed to function within an operating temperature range of -30°C to +65°C.

What communication interfaces does the IS215UCVEH2A support?

- It supports 10BaseT/100BaseTX Ethernet via an RJ-45 connector.

Is the IS215UCVEH2A suitable for applications beyond turbine control?

- While primarily designed for turbine control, its robust processing capabilities make it adaptable for various industrial automation applications.

What are the physical dimensions of this control card?

- The card measures 82.6 x 41.9 mm.

How does the IS215UCVEH2A enhance system reliability?

- Its high-performance processor and reliable memory configurations ensure stable and efficient system operations.

What makes the IS215UCVEH2A different from other VME control modules?

- Its combination of high-speed processing, flexible memory configurations, and advanced communication capabilities makes it one of the most reliable controllers in GE’s Mark VI series.

General Electric IS215UCVEH2A VME Control Card

Manufacturer:GE

Product Number:IS215UCVEH2A

Product Type:VME Control Card

Origin:USA

Dimensions:82.6 x 41.9 mm

Weight:0.907 kg

Views:60

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS215UCVEH2A VME Control Card is a pivotal component within General Electric’s Mark VI Series, specifically designed to manage and control industrial gas and steam turbines. Functioning as a high-performance processor, this controller card efficiently handles complex control tasks, ensuring optimal performance and reliability in demanding industrial environments.

Product Specifications

| Specification | Details |

|---|---|

| Processor | 300 MHz Intel Celeron |

| Memory | 16 MB or 128 MB Flash Memory; 32 MB DRAM |

| Ethernet | 10BaseT/100BaseTX (RJ-45) |

| Dimensions | 82.6 x 41.9 mm |

| Weight | 0.907 kg |

| Operating Temperature | -30°C to +65°C |

| Power Requirements | +5 V DC (6 A typical, 8 A max); +12 V DC (180 mA typical, 250 mA max); -12 V DC (180 mA typical, 250 mA max) |

Applications

The IS215UCVEH2A is integral to GE’s Speedtronic Mark VI control systems, primarily deployed in:

Gas and Steam Turbine Control: Ensures precise operation and monitoring of turbine systems in power generation plants.

Industrial Automation: Manages complex processes in manufacturing and other industrial settings requiring reliable control solutions.

Advantages

High Performance: Equipped with a robust 300 MHz Intel Celeron processor, it adeptly handles intricate control tasks.

Versatile Memory Options: Offers flexibility with 16 MB or 128 MB Flash Memory configurations, complemented by 32 MB DRAM for efficient data processing.

Seamless Integration: Designed to integrate smoothly within VME-based backplane systems, facilitating robust communication and data transfer.

Frequently Asked Questions (FAQ)

What role does the IS215UCVEH2A play in turbine control systems?

- It functions as the central processing unit, executing control algorithms to manage turbine operations effectively.

Is the IS215UCVEH2A compatible with other GE control systems?

- Yes, it is designed for seamless integration within GE’s Mark VI Series control systems.

What types of memory are utilized in this control card?

- It features 16 MB or 128 MB of Flash Memory and 32 MB of DRAM.

What are the power requirements for the IS215UCVEH2A?

- It requires +5 V DC (6 A typical, 8 A max), +12 V DC (180 mA typical, 250 mA max), and -12 V DC (180 mA typical, 250 mA max).

Can this control card operate in harsh environmental conditions?

- Yes, it is designed to function within an operating temperature range of -30°C to +65°C.

What communication interfaces does the IS215UCVEH2A support?

- It supports 10BaseT/100BaseTX Ethernet via an RJ-45 connector.

Is the IS215UCVEH2A suitable for applications beyond turbine control?

- While primarily designed for turbine control, its robust processing capabilities make it adaptable for various industrial automation applications.

What are the physical dimensions of this control card?

- The card measures 82.6 x 41.9 mm.

How does the IS215UCVEH2A enhance system reliability?

- Its high-performance processor and reliable memory configurations ensure stable and efficient system operations.

What makes the IS215UCVEH2A different from other VME control modules?

- Its combination of high-speed processing, flexible memory configurations, and advanced communication capabilities makes it one of the most reliable controllers in GE’s Mark VI series.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...