Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

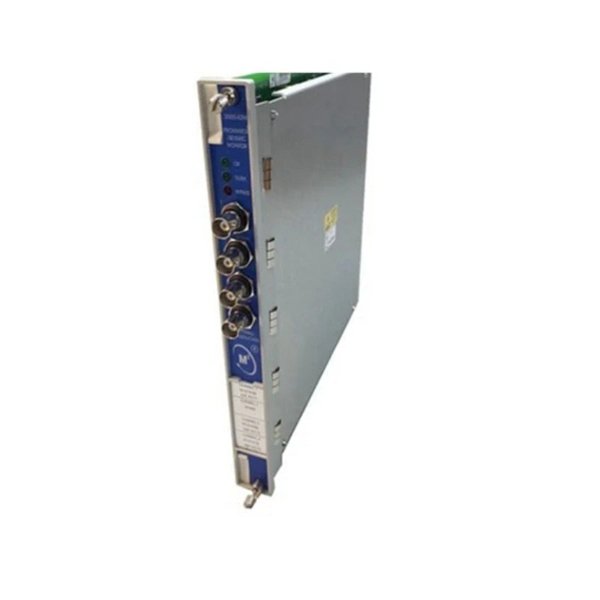

Bently Nevada 3500/42 138700-01 Shaft Absolute I/O Module

Manufacturer:Bently Nevada

Product Number:3500/42 138700-01

Product Type:Shaft Absolute I/O Module

Origin:USA

Dimensions:241.3 x 24.4 x 163.1mm

Weight :0.46 kg

Views:81

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42 138700-01 is a highly reliable Proximitor Seismic Monitor Module designed for continuous monitoring of machinery vibration in critical industrial applications. Part of the Bently Nevada 3500 Series, this module provides accurate seismic measurements, helping to prevent unexpected machinery failure and optimize predictive maintenance programs. The device integrates seamlessly with the 3500 rack system and communicates vibration data to the control and monitoring systems. Its robust design ensures stable operation even in harsh environments.

The 138700-01 model is particularly suited for turbines, compressors, pumps, and other rotating machinery where seismic activity can indicate bearing failures or other critical mechanical issues. Its precision sensors detect subtle vibration patterns, enabling early detection of mechanical anomalies.

Advantages

High Accuracy: Provides precise measurement of seismic activity to prevent machinery damage.

Reliability: Engineered for continuous operation in industrial environments.

Easy Integration: Compatible with existing 3500 Series racks and monitoring systems.

Early Fault Detection: Enables predictive maintenance by detecting early warning signs.

Durable Design: Resistant to vibration, shock, and temperature variations.

Scalable System: Can be expanded with additional modules to monitor multiple machinery units simultaneously.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/42 138700-01 |

| Module Type | Proximitor Seismic Monitor Module |

| Input Channels | 2 per module |

| Output Type | Analog and digital vibration signals |

| Measurement Range | ±50 mm/s velocity or equivalent |

| Frequency Response | 0.5 Hz to 1 kHz |

| Accuracy | ±1% of full scale |

| Power Supply | 24 VDC nominal |

| Power Consumption | 4 W typical |

| Operating Temperature | -40°C to +70°C |

| Dimensions (H×W×D) | 241.3 x 24.4 x 163.1mm |

| Weight | 0.46 kg |

| Rack Compatibility | Bently Nevada 3500 Series |

| Alarm Output | Configurable relay contacts |

| Certification | CE, UL |

Product Applications

-

Continuous monitoring of steam and gas turbines.

-

Vibration analysis in compressors and pumps.

-

Seismic monitoring for rotating machinery in power plants.

-

Early fault detection in industrial process machinery.

-

Condition-based maintenance programs in oil & gas, chemical, and petrochemical plants.

-

Integration with SCADA and DCS systems for remote monitoring.

FAQ

Q1: What is the purpose of the Bently Nevada 3500/42 138700-01 module?

-

It monitors seismic vibrations in rotating machinery to detect potential faults before they cause failure.

Q2: How many input channels does the module support?

-

The module supports 2 input channels for connecting seismic sensors.

Q3: Can this module work with older 3500 Series racks?

-

Yes, it is fully compatible with all standard Bently Nevada 3500 Series racks.

Q4: What is the operating temperature range?

-

The module operates reliably from -40°C to +70°C.

Q5: How does this module help in predictive maintenance?

-

By providing real-time vibration data, it allows operators to detect abnormalities and plan maintenance before machinery damage occurs.

Q6: Is the module certified for industrial use?

-

Yes, it carries CE and UL certifications for safety and compliance.

Q7: What type of outputs does the module provide?

-

It provides both analog and digital vibration outputs, along with configurable alarm relays.

Q8: Can the module monitor multiple machines?

-

Each module monitors two channels; multiple modules can be installed in the same rack for broader coverage.

Q9: What is the module’s measurement accuracy?

-

The accuracy is ±1% of full scale across its measurement range.

Q10: How should the module be installed?

-

It should be inserted into a 3500 Series rack and connected to seismic sensors following standard installation guidelines provided in the manual.

Bently Nevada 3500/42 138700-01 Shaft Absolute I/O Module

Manufacturer:Bently Nevada

Product Number:3500/42 138700-01

Product Type:Shaft Absolute I/O Module

Origin:USA

Dimensions:241.3 x 24.4 x 163.1mm

Weight :0.46 kg

Views:81

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42 138700-01 is a highly reliable Proximitor Seismic Monitor Module designed for continuous monitoring of machinery vibration in critical industrial applications. Part of the Bently Nevada 3500 Series, this module provides accurate seismic measurements, helping to prevent unexpected machinery failure and optimize predictive maintenance programs. The device integrates seamlessly with the 3500 rack system and communicates vibration data to the control and monitoring systems. Its robust design ensures stable operation even in harsh environments.

The 138700-01 model is particularly suited for turbines, compressors, pumps, and other rotating machinery where seismic activity can indicate bearing failures or other critical mechanical issues. Its precision sensors detect subtle vibration patterns, enabling early detection of mechanical anomalies.

Advantages

High Accuracy: Provides precise measurement of seismic activity to prevent machinery damage.

Reliability: Engineered for continuous operation in industrial environments.

Easy Integration: Compatible with existing 3500 Series racks and monitoring systems.

Early Fault Detection: Enables predictive maintenance by detecting early warning signs.

Durable Design: Resistant to vibration, shock, and temperature variations.

Scalable System: Can be expanded with additional modules to monitor multiple machinery units simultaneously.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/42 138700-01 |

| Module Type | Proximitor Seismic Monitor Module |

| Input Channels | 2 per module |

| Output Type | Analog and digital vibration signals |

| Measurement Range | ±50 mm/s velocity or equivalent |

| Frequency Response | 0.5 Hz to 1 kHz |

| Accuracy | ±1% of full scale |

| Power Supply | 24 VDC nominal |

| Power Consumption | 4 W typical |

| Operating Temperature | -40°C to +70°C |

| Dimensions (H×W×D) | 241.3 x 24.4 x 163.1mm |

| Weight | 0.46 kg |

| Rack Compatibility | Bently Nevada 3500 Series |

| Alarm Output | Configurable relay contacts |

| Certification | CE, UL |

Product Applications

-

Continuous monitoring of steam and gas turbines.

-

Vibration analysis in compressors and pumps.

-

Seismic monitoring for rotating machinery in power plants.

-

Early fault detection in industrial process machinery.

-

Condition-based maintenance programs in oil & gas, chemical, and petrochemical plants.

-

Integration with SCADA and DCS systems for remote monitoring.

FAQ

Q1: What is the purpose of the Bently Nevada 3500/42 138700-01 module?

-

It monitors seismic vibrations in rotating machinery to detect potential faults before they cause failure.

Q2: How many input channels does the module support?

-

The module supports 2 input channels for connecting seismic sensors.

Q3: Can this module work with older 3500 Series racks?

-

Yes, it is fully compatible with all standard Bently Nevada 3500 Series racks.

Q4: What is the operating temperature range?

-

The module operates reliably from -40°C to +70°C.

Q5: How does this module help in predictive maintenance?

-

By providing real-time vibration data, it allows operators to detect abnormalities and plan maintenance before machinery damage occurs.

Q6: Is the module certified for industrial use?

-

Yes, it carries CE and UL certifications for safety and compliance.

Q7: What type of outputs does the module provide?

-

It provides both analog and digital vibration outputs, along with configurable alarm relays.

Q8: Can the module monitor multiple machines?

-

Each module monitors two channels; multiple modules can be installed in the same rack for broader coverage.

Q9: What is the module’s measurement accuracy?

-

The accuracy is ±1% of full scale across its measurement range.

Q10: How should the module be installed?

-

It should be inserted into a 3500 Series rack and connected to seismic sensors following standard installation guidelines provided in the manual.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...