Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

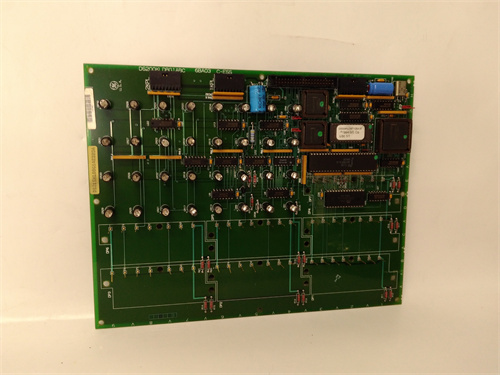

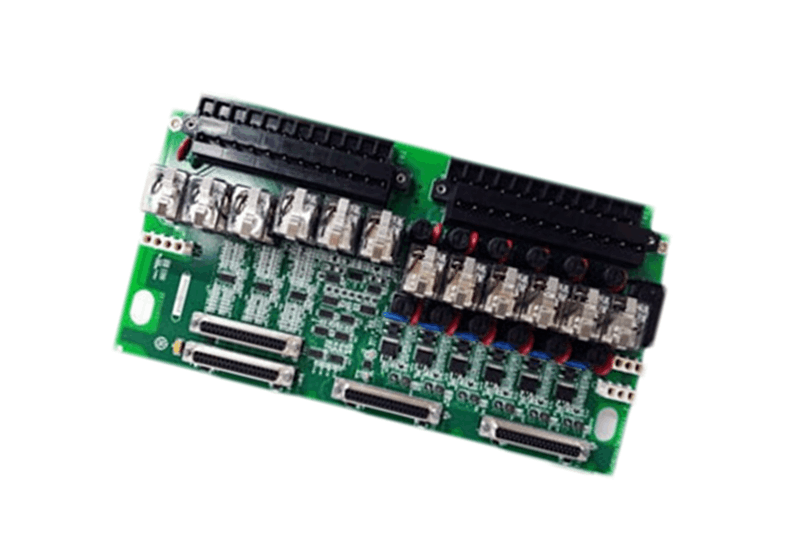

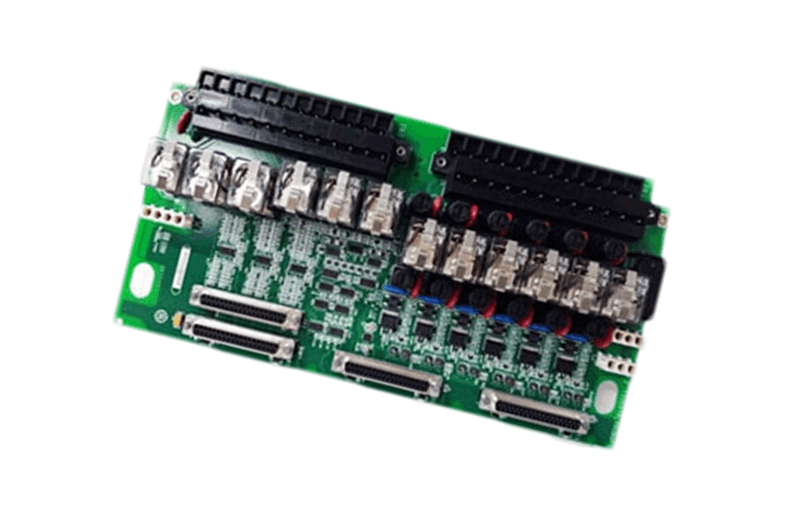

General Electric IS200PDOAH1B Turbine Protection Board

Manufacturer:GE

Product Number:IS200PDOAH1B

Product Type:Turbine Protection Board

Origin:USA

Dimensions:127 x 127 x 132 mm

Weight:0.4 kg

Views:19

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200PDOAH1B Turbine Protection Board is an advanced safety and control module engineered for GE Mark VI and Mark VIe turbine control systems. Designed to provide rapid and reliable shutdown commands, it monitors critical operating conditions—such as overspeed, vibration, and pressure—to protect turbines from damage during abnormal events. The board incorporates high-speed logic, redundant signal paths, and galvanic isolation to ensure dependable operation in demanding industrial environments, including gas, steam, and hydroelectric power generation.

Product Specifications

| Parameter | Description |

|---|---|

| Model | GE IS200PDOAH1B Turbine Protection Board |

| Primary Function | Monitors and executes emergency turbine trip commands |

| Input Voltage | 24 V DC nominal (18–30 V DC operating range) |

| Power Consumption | ≤12 W typical |

| Input Channels | Up to 16 configurable digital/analog protection inputs |

| Output Channels | 8 high-speed trip outputs, optically isolated |

| Signal Type | Differential high-speed logic, fail-safe design |

| Response Time | <10 ms from fault detection to trip activation |

| Isolation Voltage | 2500 V RMS between input, logic, and output sections |

| Operating Temperature | –20 °C to +65 °C |

| Cooling | Natural convection (forced-air optional) |

| Dimensions | 127 x 127 x 132 mm |

| Weight | 0.4 kg |

| Compliance | CE, UL, and RoHS |

| Protection Features | Over-voltage, ESD suppression, short-circuit protection, self-diagnostic monitoring |

Applications

The IS200PDOAH1B Turbine Protection Board is widely deployed in:

Gas and Steam Turbines – Ensuring rapid protective action during overspeed or pressure anomalies.

Hydroelectric Generation – Safeguarding critical generator components from sudden load changes.

Industrial Process Plants – Providing emergency trip control in refineries, petrochemical facilities, and power stations.

Retrofit Projects – Modernizing legacy systems to meet contemporary safety and reliability standards.

Advantages

Fast Response – High-speed logic enables turbine trip commands in under 10 ms.

Robust Isolation – 2500 V RMS isolation protects control electronics from high-voltage transients.

Redundant Architecture – Dual-signal paths and hot-swap capability enhance system availability.

Comprehensive Diagnostics – Continuous self-tests and LED indicators simplify maintenance and fault detection.

Flexible Integration – Seamless compatibility with GE Mark VI/VIe systems for new installations or upgrades.

Low Power Draw – Efficient design reduces energy consumption and heat buildup.

FAQ

What is the main protective role of the IS200PDOAH1B?

It detects critical turbine conditions—such as overspeed or severe vibration—and issues immediate trip signals to shut down the turbine safely.

How quickly can it respond to a trip condition?

The board provides a typical fault-to-trip response time of less than 10 milliseconds, ensuring rapid shutdown.

What kind of input signals are supported?

It supports both digital and analog protection inputs, including speed probes, pressure switches, and vibration transducers.

Is galvanic isolation provided?

Yes, the board offers 2500 V RMS galvanic isolation between input, logic, and output circuits to prevent ground loops and surges.

Can it be hot-swapped during operation?

Yes, the design supports hot-swapping, allowing maintenance or replacement without shutting down the turbine control system.

How are fault conditions indicated?

Front-edge LED indicators display power status, communication activity, and fault states for quick on-site diagnostics.

Does it support redundant configurations?

Yes, it can be deployed in dual redundant architectures to maintain protection even if one board fails.

What communication protocol is used for system integration?

The board communicates via the Mark VI/VIe high-speed proprietary control bus for real-time data exchange.

How are trip outputs protected against short circuits?

Each output channel includes electronic current limiting and thermal shutdown features to protect against short-circuit faults.

What is the maximum cable length for input sensors?

The board supports shielded twisted-pair cabling up to 100 meters for most sensor types without signal degradation.

General Electric IS200PDOAH1B Turbine Protection Board

Manufacturer:GE

Product Number:IS200PDOAH1B

Product Type:Turbine Protection Board

Origin:USA

Dimensions:127 x 127 x 132 mm

Weight:0.4 kg

Views:19

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200PDOAH1B Turbine Protection Board is an advanced safety and control module engineered for GE Mark VI and Mark VIe turbine control systems. Designed to provide rapid and reliable shutdown commands, it monitors critical operating conditions—such as overspeed, vibration, and pressure—to protect turbines from damage during abnormal events. The board incorporates high-speed logic, redundant signal paths, and galvanic isolation to ensure dependable operation in demanding industrial environments, including gas, steam, and hydroelectric power generation.

Product Specifications

| Parameter | Description |

|---|---|

| Model | GE IS200PDOAH1B Turbine Protection Board |

| Primary Function | Monitors and executes emergency turbine trip commands |

| Input Voltage | 24 V DC nominal (18–30 V DC operating range) |

| Power Consumption | ≤12 W typical |

| Input Channels | Up to 16 configurable digital/analog protection inputs |

| Output Channels | 8 high-speed trip outputs, optically isolated |

| Signal Type | Differential high-speed logic, fail-safe design |

| Response Time | <10 ms from fault detection to trip activation |

| Isolation Voltage | 2500 V RMS between input, logic, and output sections |

| Operating Temperature | –20 °C to +65 °C |

| Cooling | Natural convection (forced-air optional) |

| Dimensions | 127 x 127 x 132 mm |

| Weight | 0.4 kg |

| Compliance | CE, UL, and RoHS |

| Protection Features | Over-voltage, ESD suppression, short-circuit protection, self-diagnostic monitoring |

Applications

The IS200PDOAH1B Turbine Protection Board is widely deployed in:

Gas and Steam Turbines – Ensuring rapid protective action during overspeed or pressure anomalies.

Hydroelectric Generation – Safeguarding critical generator components from sudden load changes.

Industrial Process Plants – Providing emergency trip control in refineries, petrochemical facilities, and power stations.

Retrofit Projects – Modernizing legacy systems to meet contemporary safety and reliability standards.

Advantages

Fast Response – High-speed logic enables turbine trip commands in under 10 ms.

Robust Isolation – 2500 V RMS isolation protects control electronics from high-voltage transients.

Redundant Architecture – Dual-signal paths and hot-swap capability enhance system availability.

Comprehensive Diagnostics – Continuous self-tests and LED indicators simplify maintenance and fault detection.

Flexible Integration – Seamless compatibility with GE Mark VI/VIe systems for new installations or upgrades.

Low Power Draw – Efficient design reduces energy consumption and heat buildup.

FAQ

What is the main protective role of the IS200PDOAH1B?

It detects critical turbine conditions—such as overspeed or severe vibration—and issues immediate trip signals to shut down the turbine safely.

How quickly can it respond to a trip condition?

The board provides a typical fault-to-trip response time of less than 10 milliseconds, ensuring rapid shutdown.

What kind of input signals are supported?

It supports both digital and analog protection inputs, including speed probes, pressure switches, and vibration transducers.

Is galvanic isolation provided?

Yes, the board offers 2500 V RMS galvanic isolation between input, logic, and output circuits to prevent ground loops and surges.

Can it be hot-swapped during operation?

Yes, the design supports hot-swapping, allowing maintenance or replacement without shutting down the turbine control system.

How are fault conditions indicated?

Front-edge LED indicators display power status, communication activity, and fault states for quick on-site diagnostics.

Does it support redundant configurations?

Yes, it can be deployed in dual redundant architectures to maintain protection even if one board fails.

What communication protocol is used for system integration?

The board communicates via the Mark VI/VIe high-speed proprietary control bus for real-time data exchange.

How are trip outputs protected against short circuits?

Each output channel includes electronic current limiting and thermal shutdown features to protect against short-circuit faults.

What is the maximum cable length for input sensors?

The board supports shielded twisted-pair cabling up to 100 meters for most sensor types without signal degradation.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...