Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

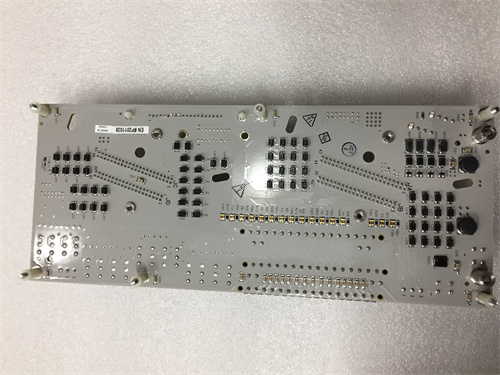

Honeywell FC-IOCHAS-0003R Chassis For Redundant I/O Module

Manufacturer:Honeywell

Product Number:FC-IOCHAS-0003R

Product Type:Chassis For Redundant I/O Module

Origin:USA

Dimensions:222.4 x 482.6 x 280 mm

Weight:8.7 kg

Views:108

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell FC-IOCHAS-0003R Chassis for Redundant I/O Module is a high-performance industrial chassis specifically engineered for hosting redundant I/O modules within Honeywell’s Experion Process Knowledge System (PKS). Designed for critical process control environments, it provides robust support for dual-channel redundant I/O configurations, ensuring maximum reliability and system availability.

This chassis features a dual redundant backplane for high-speed communication and fault-tolerant power distribution, making it ideal for applications where system uptime is non-negotiable. Its industrial-grade construction, seamless integration with Honeywell C300 controllers, and compatibility with both analog and digital I/O modules make it a preferred choice for large-scale distributed control systems.

Product Specifications

| Parameter | Details |

|---|---|

| Model | Honeywell FC-IOCHAS-0003R |

| Type | Chassis for Redundant I/O Module |

| System Compatibility | Honeywell Experion PKS |

| Backplane Architecture | Dual redundant high-speed communication bus |

| Power Distribution | Dual redundant power rails |

| I/O Module Support | Analog and digital redundant I/O modules |

| Slot Capacity | Multiple high-density I/O slots |

| Mounting Type | Rack/panel mounting |

| Material | Industrial-grade coated steel/aluminum |

| Operating Temperature | 0°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Compliance Standards | CE, UL, RoHS, IEC |

| Dimensions (L x W x H) | 222.4 x 482.6 x 280 mm |

| Weight | 8.7 kg |

Product Applications

Distributed Control Systems (DCS): Serves as a central component for redundant I/O in Experion PKS-based process automation systems.

High-Availability Process Plants: Designed for industries like oil & gas, refining, and power generation where continuous operation is critical.

Dual-Channel I/O Architecture: Enables hot-standby redundancy for fault-tolerant control strategies.

Plant Modernization Projects: Supports integration into both greenfield installations and brownfield upgrades.

Centralized and Field Installation: Can be mounted in control rooms or remote field enclosures for flexible system architecture.

Large-Scale Signal Management: Optimized for high-density analog and digital I/O configurations.

Product Advantages

Full Redundancy: Dual communication and power backplane ensures maximum system uptime and failover protection.

Hot-Swappable Modules: Allows replacement and maintenance without shutting down the system.

Seamless PKS Integration: Fully compatible with Honeywell’s Experion PKS environment for easy deployment.

Industrial Durability: Built with rugged materials to withstand demanding operating conditions.

Flexible I/O Support: Accommodates both analog and digital redundant I/O modules in one chassis.

Low-Latency Communication: Optimized for high-speed data transfer to meet real-time control requirements.

FAQ

Does the FC-IOCHAS-0003R support mixed analog and digital I/O modules?

Yes, it is designed to handle both analog and digital redundant I/O modules simultaneously.

What type of backplane communication does the chassis use?

It uses a dual redundant high-speed communication bus optimized for Honeywell Experion PKS systems.

Is hot-swapping supported for I/O modules installed in this chassis?

Yes, the chassis supports hot-swapping of I/O modules without system shutdown.

Can this chassis be used in mission-critical process automation applications?

Absolutely. It is designed for high-availability control systems that demand fault tolerance.

Does the chassis provide redundant power distribution?

Yes, it incorporates dual power rails to ensure uninterrupted operation in case of power supply failure.

Is it compatible with existing Experion PKS installations?

Yes, it can be seamlessly integrated into new and existing Experion PKS-based DCS architectures.

What is the benefit of a redundant backplane in this chassis?

The redundant backplane ensures continuous communication between controllers and I/O modules, even during a fault.

Can the FC-IOCHAS-0003R be mounted in both centralized and distributed installations?

Yes, it is suitable for both control room rack installations and field enclosures.

Does it support high-density I/O configurations for large process plants?

Yes, the chassis is optimized for high-density analog and digital I/O setups.

Is the chassis compliant with industrial safety and EMC standards?

Yes, it meets CE, UL, RoHS, and IEC standards for industrial automation equipment.

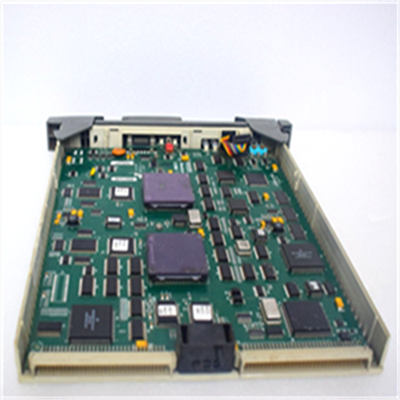

Honeywell FC-IOCHAS-0003R Chassis For Redundant I/O Module

Manufacturer:Honeywell

Product Number:FC-IOCHAS-0003R

Product Type:Chassis For Redundant I/O Module

Origin:USA

Dimensions:222.4 x 482.6 x 280 mm

Weight:8.7 kg

Views:108

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell FC-IOCHAS-0003R Chassis for Redundant I/O Module is a high-performance industrial chassis specifically engineered for hosting redundant I/O modules within Honeywell’s Experion Process Knowledge System (PKS). Designed for critical process control environments, it provides robust support for dual-channel redundant I/O configurations, ensuring maximum reliability and system availability.

This chassis features a dual redundant backplane for high-speed communication and fault-tolerant power distribution, making it ideal for applications where system uptime is non-negotiable. Its industrial-grade construction, seamless integration with Honeywell C300 controllers, and compatibility with both analog and digital I/O modules make it a preferred choice for large-scale distributed control systems.

Product Specifications

| Parameter | Details |

|---|---|

| Model | Honeywell FC-IOCHAS-0003R |

| Type | Chassis for Redundant I/O Module |

| System Compatibility | Honeywell Experion PKS |

| Backplane Architecture | Dual redundant high-speed communication bus |

| Power Distribution | Dual redundant power rails |

| I/O Module Support | Analog and digital redundant I/O modules |

| Slot Capacity | Multiple high-density I/O slots |

| Mounting Type | Rack/panel mounting |

| Material | Industrial-grade coated steel/aluminum |

| Operating Temperature | 0°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Compliance Standards | CE, UL, RoHS, IEC |

| Dimensions (L x W x H) | 222.4 x 482.6 x 280 mm |

| Weight | 8.7 kg |

Product Applications

Distributed Control Systems (DCS): Serves as a central component for redundant I/O in Experion PKS-based process automation systems.

High-Availability Process Plants: Designed for industries like oil & gas, refining, and power generation where continuous operation is critical.

Dual-Channel I/O Architecture: Enables hot-standby redundancy for fault-tolerant control strategies.

Plant Modernization Projects: Supports integration into both greenfield installations and brownfield upgrades.

Centralized and Field Installation: Can be mounted in control rooms or remote field enclosures for flexible system architecture.

Large-Scale Signal Management: Optimized for high-density analog and digital I/O configurations.

Product Advantages

Full Redundancy: Dual communication and power backplane ensures maximum system uptime and failover protection.

Hot-Swappable Modules: Allows replacement and maintenance without shutting down the system.

Seamless PKS Integration: Fully compatible with Honeywell’s Experion PKS environment for easy deployment.

Industrial Durability: Built with rugged materials to withstand demanding operating conditions.

Flexible I/O Support: Accommodates both analog and digital redundant I/O modules in one chassis.

Low-Latency Communication: Optimized for high-speed data transfer to meet real-time control requirements.

FAQ

Does the FC-IOCHAS-0003R support mixed analog and digital I/O modules?

Yes, it is designed to handle both analog and digital redundant I/O modules simultaneously.

What type of backplane communication does the chassis use?

It uses a dual redundant high-speed communication bus optimized for Honeywell Experion PKS systems.

Is hot-swapping supported for I/O modules installed in this chassis?

Yes, the chassis supports hot-swapping of I/O modules without system shutdown.

Can this chassis be used in mission-critical process automation applications?

Absolutely. It is designed for high-availability control systems that demand fault tolerance.

Does the chassis provide redundant power distribution?

Yes, it incorporates dual power rails to ensure uninterrupted operation in case of power supply failure.

Is it compatible with existing Experion PKS installations?

Yes, it can be seamlessly integrated into new and existing Experion PKS-based DCS architectures.

What is the benefit of a redundant backplane in this chassis?

The redundant backplane ensures continuous communication between controllers and I/O modules, even during a fault.

Can the FC-IOCHAS-0003R be mounted in both centralized and distributed installations?

Yes, it is suitable for both control room rack installations and field enclosures.

Does it support high-density I/O configurations for large process plants?

Yes, the chassis is optimized for high-density analog and digital I/O setups.

Is the chassis compliant with industrial safety and EMC standards?

Yes, it meets CE, UL, RoHS, and IEC standards for industrial automation equipment.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...