Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

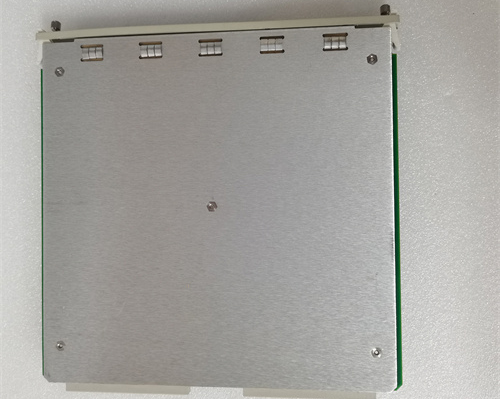

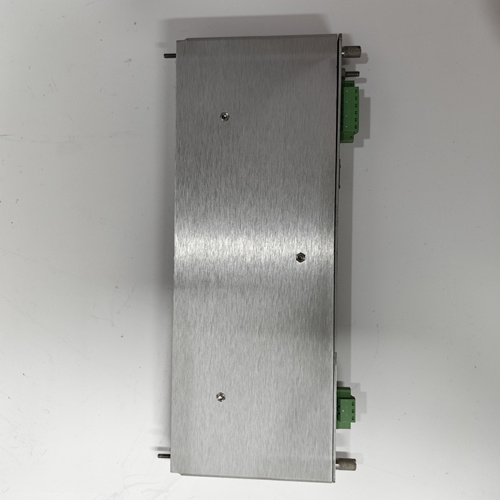

Bently Nevada 330105-02-12-05-02-CN 3300 XL 8mm Reverse Mount Proximity Probe

Manufacturer:Bently Nevada

Product Number:330105-02-12-05-02-CN

Product Type:3300 XL 8mm Reverse Mount Proximity Probe

Origin:USA

Total Length:0.5 meter

Weight:0.161kg

Views:29

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330105-02-12-05-02-CN is an 8mm reverse mount proximity probe designed for the Bently Nevada 3300 XL system. This advanced probe offers precision displacement and vibration measurements for rotating machinery, such as turbines, compressors, and motors, in industrial environments. The reverse mount configuration allows for installation in limited spaces or specific application setups, ensuring flexibility in machinery monitoring and control.

This probe is part of the Bently Nevada 3300 XL series, which is well known for its durability, accuracy, and reliable performance even in harsh conditions. The reverse mount design provides ease of installation and space efficiency, making it ideal for applications with challenging mounting requirements. Additionally, the probe employs eddy current sensing technology, ensuring minimal interference and precise readings.

The Bently Nevada 330105-02-12-05-02-CN is perfect for applications where real-time vibration and displacement monitoring is critical to prevent machinery failure. It integrates seamlessly with other Bently Nevada equipment, ensuring reliable data collection and processing.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | 330105-02-12-05-02-CN |

| Probe Type | 8mm Reverse Mount Proximity Probe |

| Total Length | 0.5 meter |

| Weight | 0.161 kg |

| Measurement Range | ±5.0 mm |

| Operating Temperature | -40°C to +120°C |

| Cable Length | 0.5 meter |

| Mounting Style | Reverse mount (compatible with Bently Nevada 3300 XL system) |

| Output Signal | 4-20 mA (depending on system configuration) |

| Sensing Element | Eddy current principle for precise measurements |

| Compliance | CE, UL, ATEX, IECEx certified |

| Application | Vibration and displacement monitoring |

| Connector Type | Lemo or equivalent (compatible with Bently Nevada systems) |

Applications

The Bently Nevada 330105-02-12-05-02-CN 8mm Reverse Mount Proximity Probe is designed for use in critical machinery monitoring and condition-based maintenance. Common applications include:

Power Generation: Monitoring turbines, generators, and motors to prevent unplanned shutdowns and improve operational efficiency.

Oil and Gas: Ensuring the health of equipment such as pumps, compressors, and turbines in refineries and drilling operations.

Mining and Heavy Industries: Providing accurate displacement and vibration measurements for heavy machinery like crushers, mills, and conveyors.

Manufacturing: Monitoring the performance of motors, pumps, and other rotating equipment in factories.

Water Treatment: Monitoring critical components like pumps, motors, and valves in water and wastewater treatment plants.

Transportation: Ensuring optimal performance of rotating machinery used in transportation systems, including railways and automated systems.

Key Advantages

High Accuracy and Precision: The 3300 XL 8mm reverse mount probe provides accurate and precise displacement and vibration measurements, ensuring reliable condition monitoring.

Compact Design: The probe’s compact size and reverse mount configuration (total length of 0.5 meter) make it ideal for installations with space constraints or unique mounting requirements.

Eddy Current Sensing Technology: The probe uses advanced eddy current sensing technology for precise, interference-free measurements, even in environments with high electromagnetic noise.

Durable and Reliable: Built to endure harsh industrial conditions, the 3300 XL probe is designed for long-term reliability, reducing the need for maintenance and improving system uptime.

Wide Temperature Range: With an operating temperature range of -40°C to +120°C, the probe can function effectively in extreme environments, from freezing temperatures to high-heat conditions.

Real-time Monitoring: The probe enables real-time monitoring of machinery, helping to detect early signs of wear, misalignment, or imbalance, which could prevent costly downtime.

Easy Installation: The reverse mount design simplifies installation in difficult-to-reach or limited space applications, offering flexibility without compromising performance.

Flexible Cable Options: The probe comes with a 0.5-meter cable, providing flexibility in installation while maintaining signal integrity over longer distances.

Compatibility: The 3300 XL probe is compatible with other Bently Nevada systems and integrates seamlessly into existing vibration monitoring setups.

Safety Compliance: Certified with CE, UL, ATEX, and IECEx safety standards, making it suitable for use in hazardous locations and ensuring safety in industrial environments.

Frequently Asked Questions (FAQ)

What is the total length of the Bently Nevada 330105-02-12-05-02-CN probe?

The total length of the probe is 0.5 meter.

What is the weight of the 3300 XL 8mm reverse mount proximity probe?

The probe weighs 0.161 kg.

What type of sensing technology does the 3300 XL proximity probe use?

The probe uses eddy current sensing technology for precise and reliable measurements.

What is the measurement range of the 3300 XL 8mm reverse mount probe?

The measurement range is ±5.0 mm.

What is the operating temperature range of the 3300 XL 8mm probe?

The operating temperature range is from -40°C to +120°C.

Can the 3300 XL proximity probe be used in hazardous environments?

Yes, the probe is certified for use in hazardous environments and meets ATEX, IECEx, CE, and UL safety standards.

What types of applications is the 3300 XL reverse mount probe used for?

The probe is commonly used for monitoring turbines, generators, motors, pumps, and other critical machinery in industries like power generation, oil and gas, mining, and water treatment.

How is the probe mounted?

The probe features a reverse mount design, which makes it suitable for installations where space is limited or in specific mounting configurations.

What type of output signal does the 3300 XL proximity probe provide?

The probe typically provides a 4-20 mA output signal, depending on the system configuration.

Is the 3300 XL 8mm reverse mount probe compatible with other Bently Nevada systems?

Yes, it is fully compatible with other Bently Nevada 3300 XL systems and can be easily integrated into existing vibration monitoring setups.

Bently Nevada 330105-02-12-05-02-CN 3300 XL 8mm Reverse Mount Proximity Probe

Manufacturer:Bently Nevada

Product Number:330105-02-12-05-02-CN

Product Type:3300 XL 8mm Reverse Mount Proximity Probe

Origin:USA

Total Length:0.5 meter

Weight:0.161kg

Views:29

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330105-02-12-05-02-CN is an 8mm reverse mount proximity probe designed for the Bently Nevada 3300 XL system. This advanced probe offers precision displacement and vibration measurements for rotating machinery, such as turbines, compressors, and motors, in industrial environments. The reverse mount configuration allows for installation in limited spaces or specific application setups, ensuring flexibility in machinery monitoring and control.

This probe is part of the Bently Nevada 3300 XL series, which is well known for its durability, accuracy, and reliable performance even in harsh conditions. The reverse mount design provides ease of installation and space efficiency, making it ideal for applications with challenging mounting requirements. Additionally, the probe employs eddy current sensing technology, ensuring minimal interference and precise readings.

The Bently Nevada 330105-02-12-05-02-CN is perfect for applications where real-time vibration and displacement monitoring is critical to prevent machinery failure. It integrates seamlessly with other Bently Nevada equipment, ensuring reliable data collection and processing.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | 330105-02-12-05-02-CN |

| Probe Type | 8mm Reverse Mount Proximity Probe |

| Total Length | 0.5 meter |

| Weight | 0.161 kg |

| Measurement Range | ±5.0 mm |

| Operating Temperature | -40°C to +120°C |

| Cable Length | 0.5 meter |

| Mounting Style | Reverse mount (compatible with Bently Nevada 3300 XL system) |

| Output Signal | 4-20 mA (depending on system configuration) |

| Sensing Element | Eddy current principle for precise measurements |

| Compliance | CE, UL, ATEX, IECEx certified |

| Application | Vibration and displacement monitoring |

| Connector Type | Lemo or equivalent (compatible with Bently Nevada systems) |

Applications

The Bently Nevada 330105-02-12-05-02-CN 8mm Reverse Mount Proximity Probe is designed for use in critical machinery monitoring and condition-based maintenance. Common applications include:

Power Generation: Monitoring turbines, generators, and motors to prevent unplanned shutdowns and improve operational efficiency.

Oil and Gas: Ensuring the health of equipment such as pumps, compressors, and turbines in refineries and drilling operations.

Mining and Heavy Industries: Providing accurate displacement and vibration measurements for heavy machinery like crushers, mills, and conveyors.

Manufacturing: Monitoring the performance of motors, pumps, and other rotating equipment in factories.

Water Treatment: Monitoring critical components like pumps, motors, and valves in water and wastewater treatment plants.

Transportation: Ensuring optimal performance of rotating machinery used in transportation systems, including railways and automated systems.

Key Advantages

High Accuracy and Precision: The 3300 XL 8mm reverse mount probe provides accurate and precise displacement and vibration measurements, ensuring reliable condition monitoring.

Compact Design: The probe’s compact size and reverse mount configuration (total length of 0.5 meter) make it ideal for installations with space constraints or unique mounting requirements.

Eddy Current Sensing Technology: The probe uses advanced eddy current sensing technology for precise, interference-free measurements, even in environments with high electromagnetic noise.

Durable and Reliable: Built to endure harsh industrial conditions, the 3300 XL probe is designed for long-term reliability, reducing the need for maintenance and improving system uptime.

Wide Temperature Range: With an operating temperature range of -40°C to +120°C, the probe can function effectively in extreme environments, from freezing temperatures to high-heat conditions.

Real-time Monitoring: The probe enables real-time monitoring of machinery, helping to detect early signs of wear, misalignment, or imbalance, which could prevent costly downtime.

Easy Installation: The reverse mount design simplifies installation in difficult-to-reach or limited space applications, offering flexibility without compromising performance.

Flexible Cable Options: The probe comes with a 0.5-meter cable, providing flexibility in installation while maintaining signal integrity over longer distances.

Compatibility: The 3300 XL probe is compatible with other Bently Nevada systems and integrates seamlessly into existing vibration monitoring setups.

Safety Compliance: Certified with CE, UL, ATEX, and IECEx safety standards, making it suitable for use in hazardous locations and ensuring safety in industrial environments.

Frequently Asked Questions (FAQ)

What is the total length of the Bently Nevada 330105-02-12-05-02-CN probe?

The total length of the probe is 0.5 meter.

What is the weight of the 3300 XL 8mm reverse mount proximity probe?

The probe weighs 0.161 kg.

What type of sensing technology does the 3300 XL proximity probe use?

The probe uses eddy current sensing technology for precise and reliable measurements.

What is the measurement range of the 3300 XL 8mm reverse mount probe?

The measurement range is ±5.0 mm.

What is the operating temperature range of the 3300 XL 8mm probe?

The operating temperature range is from -40°C to +120°C.

Can the 3300 XL proximity probe be used in hazardous environments?

Yes, the probe is certified for use in hazardous environments and meets ATEX, IECEx, CE, and UL safety standards.

What types of applications is the 3300 XL reverse mount probe used for?

The probe is commonly used for monitoring turbines, generators, motors, pumps, and other critical machinery in industries like power generation, oil and gas, mining, and water treatment.

How is the probe mounted?

The probe features a reverse mount design, which makes it suitable for installations where space is limited or in specific mounting configurations.

What type of output signal does the 3300 XL proximity probe provide?

The probe typically provides a 4-20 mA output signal, depending on the system configuration.

Is the 3300 XL 8mm reverse mount probe compatible with other Bently Nevada systems?

Yes, it is fully compatible with other Bently Nevada 3300 XL systems and can be easily integrated into existing vibration monitoring setups.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...