Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

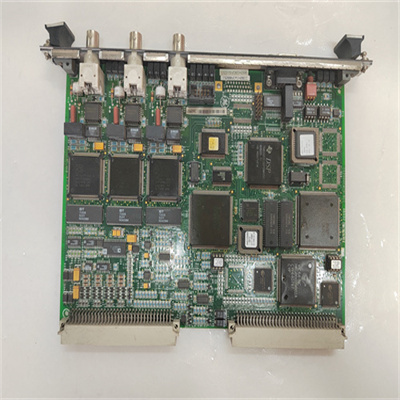

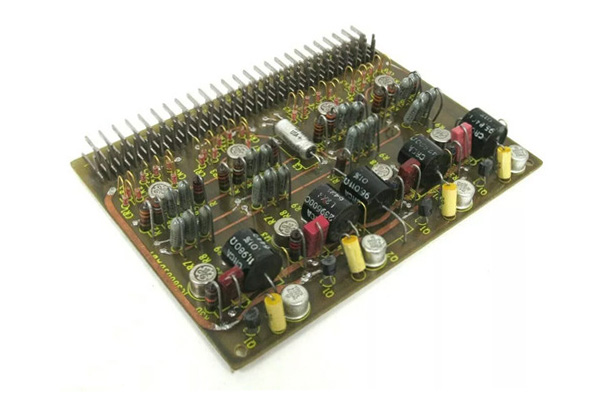

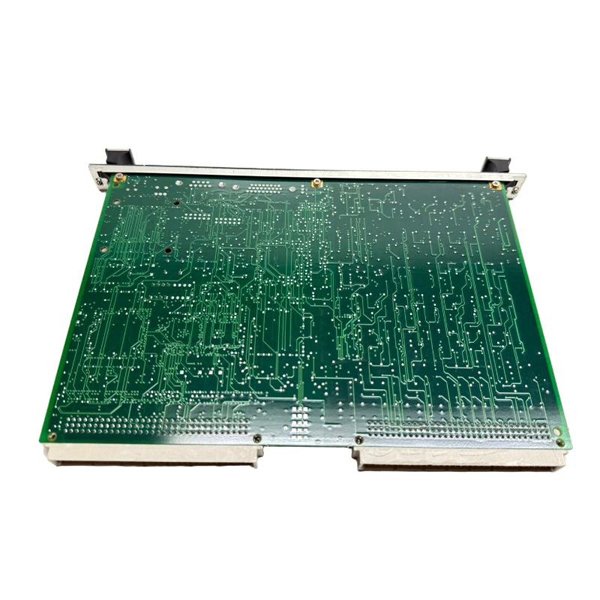

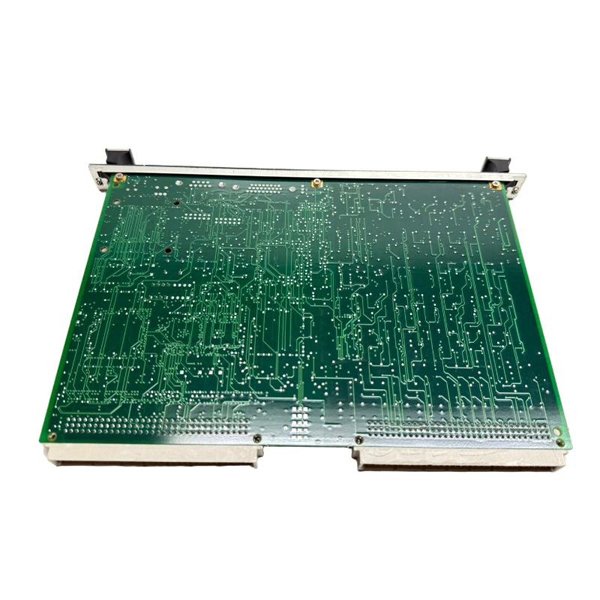

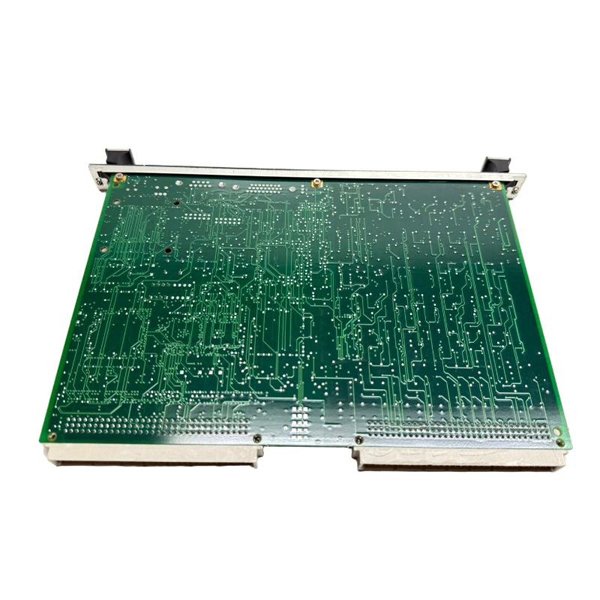

General Electric IS200VVIBH1CAC Vibration Monitor Board

Manufacturer:GE

Product Number:IS200VVIBH1CAC

Product Type:Vibration Monitor Board

Origin:USA

Dimensions:240 x 110 x 25 mm

Weight:0.5 kg

Views:39

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200VVIBH1CAC Vibration Monitor Board is a precision-engineered component designed to monitor vibration signals in industrial machinery and rotating equipment. It forms part of the IS200 series vibration monitoring systems, widely used in power generation, oil and gas, and manufacturing sectors to enhance equipment reliability and predict maintenance needs.

This board captures and processes vibration data from various sensors, converting it into actionable information for predictive diagnostics and protection systems. With high sensitivity and accuracy, the IS200VVIBH1CAC supports real-time condition monitoring to prevent costly downtime caused by mechanical failures.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | IS200VVIBH1CAC |

| Function | Vibration Monitor Board |

| Input Channels | Multiple vibration sensor inputs |

| Signal Type | Accelerometer or velocity sensor inputs |

| Signal Conditioning | Amplification, filtering, and analog-to-digital conversion |

| Output | Processed vibration signals for system integration |

| Frequency Range | Typically 0.5 Hz to 10 kHz (model-dependent) |

| Sensitivity | High sensitivity to detect low amplitude vibrations |

| Communication Interface | Compatible with IS200 series systems |

| Power Supply | Supplied via system backplane |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% RH, non-condensing |

| Mounting Type | Rack or card slot mounted |

| Dimensions (H × W × D) | 240 x 110 x 25 mm |

| Weight | 0.5 kg |

| Certifications | CE, UL, CSA, IEC compliant |

Product Applications

The IS200VVIBH1CAC is used extensively in industries requiring continuous vibration monitoring to safeguard equipment health:

Steam Turbines and Generators: Monitors rotor vibration to prevent unplanned outages.

Compressors and Pumps: Detects abnormal vibration indicating misalignment or bearing wear.

Gas Turbines: Provides early warning of imbalance, looseness, or blade pass frequency issues.

Motors and Fans: Helps monitor mechanical condition and optimize maintenance schedules.

Industrial Manufacturing Equipment: Protects high-speed rotating machinery from catastrophic failure.

Pulp and Paper Mills: Ensures operational reliability of rollers and presses.

Product Advantages

High Precision Monitoring: Offers accurate vibration data acquisition for early fault detection.

Robust Signal Conditioning: Ensures clean, reliable signals through amplification and filtering.

Seamless System Integration: Designed to interface smoothly with GE’s IS200 vibration monitoring platforms.

Wide Frequency Response: Captures a broad spectrum of vibration frequencies for comprehensive analysis.

Durable Construction: Engineered to operate reliably in harsh industrial environments.

Simplified Maintenance: Modular card design allows quick replacement and upgrades.

Real-Time Diagnostics: Enables continuous monitoring and rapid response to mechanical issues.

Improves Asset Management: Helps optimize maintenance cycles and reduce unexpected downtime.

FAQ

What types of vibration sensors can be connected to the IS200VVIBH1CAC?

It supports accelerometers and velocity sensors typically used in industrial vibration monitoring.

What is the frequency range the board can monitor?

The board covers approximately 0.5 Hz to 10 kHz, depending on sensor and system configuration.

How does the board process vibration signals?

It amplifies, filters, and converts analog signals into digital data for the IS200 system.

Is the module compatible with all IS200 series equipment?

Yes, it is designed for seamless compatibility with IS200 series vibration monitoring systems.

What power supply does the board require?

It receives power directly through the IS200 system backplane.

Can the board operate in harsh industrial environments?

Yes, it is built to withstand temperature extremes and typical industrial conditions.

How is the board installed in the system?

It is rack or card slot mounted within the IS200 vibration monitoring chassis.

Does the board provide any self-diagnostic features?

Diagnostics depend on the overall IS200 system; the board supports reliable signal transmission.

Can it detect low-level vibrations?

Yes, it offers high sensitivity to capture low-amplitude vibration signals.

Is the board certified for industrial safety standards?

Yes, it holds CE, UL, CSA, and IEC certifications ensuring compliance with industrial standards.

General Electric IS200VVIBH1CAC Vibration Monitor Board

Manufacturer:GE

Product Number:IS200VVIBH1CAC

Product Type:Vibration Monitor Board

Origin:USA

Dimensions:240 x 110 x 25 mm

Weight:0.5 kg

Views:39

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200VVIBH1CAC Vibration Monitor Board is a precision-engineered component designed to monitor vibration signals in industrial machinery and rotating equipment. It forms part of the IS200 series vibration monitoring systems, widely used in power generation, oil and gas, and manufacturing sectors to enhance equipment reliability and predict maintenance needs.

This board captures and processes vibration data from various sensors, converting it into actionable information for predictive diagnostics and protection systems. With high sensitivity and accuracy, the IS200VVIBH1CAC supports real-time condition monitoring to prevent costly downtime caused by mechanical failures.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | IS200VVIBH1CAC |

| Function | Vibration Monitor Board |

| Input Channels | Multiple vibration sensor inputs |

| Signal Type | Accelerometer or velocity sensor inputs |

| Signal Conditioning | Amplification, filtering, and analog-to-digital conversion |

| Output | Processed vibration signals for system integration |

| Frequency Range | Typically 0.5 Hz to 10 kHz (model-dependent) |

| Sensitivity | High sensitivity to detect low amplitude vibrations |

| Communication Interface | Compatible with IS200 series systems |

| Power Supply | Supplied via system backplane |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% RH, non-condensing |

| Mounting Type | Rack or card slot mounted |

| Dimensions (H × W × D) | 240 x 110 x 25 mm |

| Weight | 0.5 kg |

| Certifications | CE, UL, CSA, IEC compliant |

Product Applications

The IS200VVIBH1CAC is used extensively in industries requiring continuous vibration monitoring to safeguard equipment health:

Steam Turbines and Generators: Monitors rotor vibration to prevent unplanned outages.

Compressors and Pumps: Detects abnormal vibration indicating misalignment or bearing wear.

Gas Turbines: Provides early warning of imbalance, looseness, or blade pass frequency issues.

Motors and Fans: Helps monitor mechanical condition and optimize maintenance schedules.

Industrial Manufacturing Equipment: Protects high-speed rotating machinery from catastrophic failure.

Pulp and Paper Mills: Ensures operational reliability of rollers and presses.

Product Advantages

High Precision Monitoring: Offers accurate vibration data acquisition for early fault detection.

Robust Signal Conditioning: Ensures clean, reliable signals through amplification and filtering.

Seamless System Integration: Designed to interface smoothly with GE’s IS200 vibration monitoring platforms.

Wide Frequency Response: Captures a broad spectrum of vibration frequencies for comprehensive analysis.

Durable Construction: Engineered to operate reliably in harsh industrial environments.

Simplified Maintenance: Modular card design allows quick replacement and upgrades.

Real-Time Diagnostics: Enables continuous monitoring and rapid response to mechanical issues.

Improves Asset Management: Helps optimize maintenance cycles and reduce unexpected downtime.

FAQ

What types of vibration sensors can be connected to the IS200VVIBH1CAC?

It supports accelerometers and velocity sensors typically used in industrial vibration monitoring.

What is the frequency range the board can monitor?

The board covers approximately 0.5 Hz to 10 kHz, depending on sensor and system configuration.

How does the board process vibration signals?

It amplifies, filters, and converts analog signals into digital data for the IS200 system.

Is the module compatible with all IS200 series equipment?

Yes, it is designed for seamless compatibility with IS200 series vibration monitoring systems.

What power supply does the board require?

It receives power directly through the IS200 system backplane.

Can the board operate in harsh industrial environments?

Yes, it is built to withstand temperature extremes and typical industrial conditions.

How is the board installed in the system?

It is rack or card slot mounted within the IS200 vibration monitoring chassis.

Does the board provide any self-diagnostic features?

Diagnostics depend on the overall IS200 system; the board supports reliable signal transmission.

Can it detect low-level vibrations?

Yes, it offers high sensitivity to capture low-amplitude vibration signals.

Is the board certified for industrial safety standards?

Yes, it holds CE, UL, CSA, and IEC certifications ensuring compliance with industrial standards.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...