Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

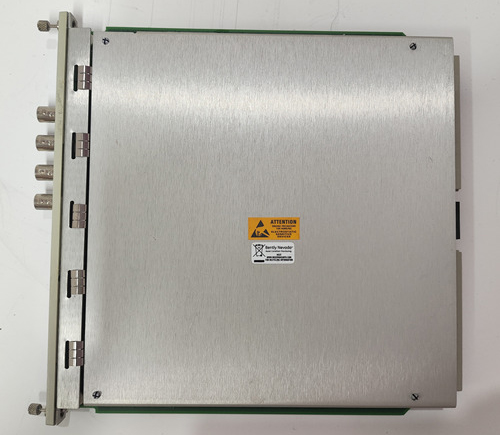

Bently Nevada 21000-28-10-00-50-04-02 Proximity Probe Housing Assemblie

Manufacturer:Bently Nevada

Product Number:21000-28-10-00-50-04-02

Product Type:Proximity Probe Housing Assemblie

Origin:USA

Housing Body Diameter:83.3 mm

Weight:1.1 kg

Views:24

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 21000-28-10-00-50-04-02 Proximity Probe Housing Assembly is designed to provide precise and reliable positioning for 3300 XL 8 mm proximity probes. Constructed from high-grade aluminum and stainless steel, it ensures durability and stable probe alignment under harsh industrial conditions. The assembly facilitates accurate shaft vibration and position monitoring in rotating machinery.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 21000-28-10-00-50-04-02 |

| Probe Compatibility | 3300 XL 8 mm Proximity Probe |

| Housing Material | Aluminum body with 304 Stainless Steel sleeve |

| Housing Body Diameter | 83.3 mm |

| Weight | 1.1 kg |

| Penetration Depth | 127 mm (5 inches) |

| Mounting Thread | 3/4-14 NPT |

| Fittings | One 3/4-14 NPT plug |

| Temperature Range | -51°C to +177°C |

| Certification | CSA Type 4, API 670 Compliant |

| Warranty | 12 months |

Applications

-

Monitoring shaft vibration and position in turbines, compressors, and motors.

-

High-precision industrial machinery alignment.

-

Critical rotating equipment requiring continuous condition monitoring.

-

Environments with high temperature and mechanical stress.

Advantages

-

Durable aluminum and stainless steel construction ensures long service life.

-

API 670 compliance guarantees high-accuracy measurements.

-

Easy installation with standard NPT threads.

-

Compatible with 3300 XL proximity probes for seamless integration.

-

Stable probe positioning reduces measurement errors.

-

Wide temperature range suitable for harsh industrial environments.

FAQ

1. What probe types are compatible with this housing?

The housing is designed for the 3300 XL 8 mm proximity probe series.

2. What is the maximum operating temperature?

The housing can operate up to 177°C (-51°C minimum).

3. Is the housing suitable for hazardous areas?

Yes, it is CSA Type 4 certified and API 670 compliant.

4. What material is the housing made from?

Aluminum body with a 304 stainless steel sleeve for durability.

5. What is the housing body diameter?

The diameter is 83.3 mm.

6. How much does the housing weigh?

The weight is 1.1 kg.

7. What mounting thread does it use?

It uses a 3/4-14 NPT thread for secure installation.

8. What is the penetration depth?

The penetration depth is 127 mm (5 inches).

9. Can it be used in turbines?

Yes, it is ideal for turbines, compressors, and other rotating machinery.

10. What maintenance is required for the housing assembly?

The housing requires periodic inspection for mechanical integrity, cleaning of probe surfaces, and verification of mounting tightness to ensure accurate vibration measurements and long-term reliability.

Bently Nevada 21000-28-10-00-50-04-02 Proximity Probe Housing Assemblie

Manufacturer:Bently Nevada

Product Number:21000-28-10-00-50-04-02

Product Type:Proximity Probe Housing Assemblie

Origin:USA

Housing Body Diameter:83.3 mm

Weight:1.1 kg

Views:24

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 21000-28-10-00-50-04-02 Proximity Probe Housing Assembly is designed to provide precise and reliable positioning for 3300 XL 8 mm proximity probes. Constructed from high-grade aluminum and stainless steel, it ensures durability and stable probe alignment under harsh industrial conditions. The assembly facilitates accurate shaft vibration and position monitoring in rotating machinery.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 21000-28-10-00-50-04-02 |

| Probe Compatibility | 3300 XL 8 mm Proximity Probe |

| Housing Material | Aluminum body with 304 Stainless Steel sleeve |

| Housing Body Diameter | 83.3 mm |

| Weight | 1.1 kg |

| Penetration Depth | 127 mm (5 inches) |

| Mounting Thread | 3/4-14 NPT |

| Fittings | One 3/4-14 NPT plug |

| Temperature Range | -51°C to +177°C |

| Certification | CSA Type 4, API 670 Compliant |

| Warranty | 12 months |

Applications

-

Monitoring shaft vibration and position in turbines, compressors, and motors.

-

High-precision industrial machinery alignment.

-

Critical rotating equipment requiring continuous condition monitoring.

-

Environments with high temperature and mechanical stress.

Advantages

-

Durable aluminum and stainless steel construction ensures long service life.

-

API 670 compliance guarantees high-accuracy measurements.

-

Easy installation with standard NPT threads.

-

Compatible with 3300 XL proximity probes for seamless integration.

-

Stable probe positioning reduces measurement errors.

-

Wide temperature range suitable for harsh industrial environments.

FAQ

1. What probe types are compatible with this housing?

The housing is designed for the 3300 XL 8 mm proximity probe series.

2. What is the maximum operating temperature?

The housing can operate up to 177°C (-51°C minimum).

3. Is the housing suitable for hazardous areas?

Yes, it is CSA Type 4 certified and API 670 compliant.

4. What material is the housing made from?

Aluminum body with a 304 stainless steel sleeve for durability.

5. What is the housing body diameter?

The diameter is 83.3 mm.

6. How much does the housing weigh?

The weight is 1.1 kg.

7. What mounting thread does it use?

It uses a 3/4-14 NPT thread for secure installation.

8. What is the penetration depth?

The penetration depth is 127 mm (5 inches).

9. Can it be used in turbines?

Yes, it is ideal for turbines, compressors, and other rotating machinery.

10. What maintenance is required for the housing assembly?

The housing requires periodic inspection for mechanical integrity, cleaning of probe surfaces, and verification of mounting tightness to ensure accurate vibration measurements and long-term reliability.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...