Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

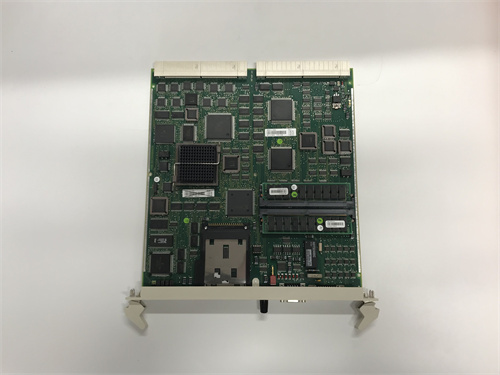

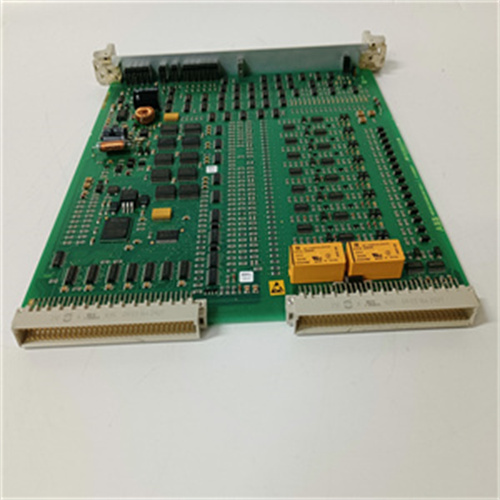

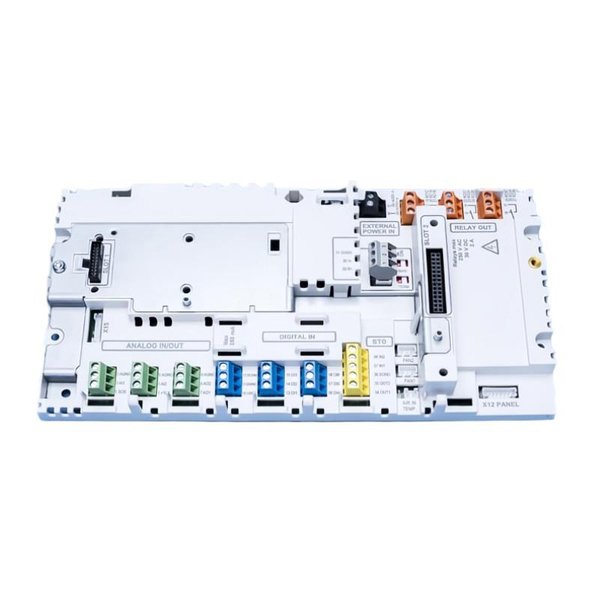

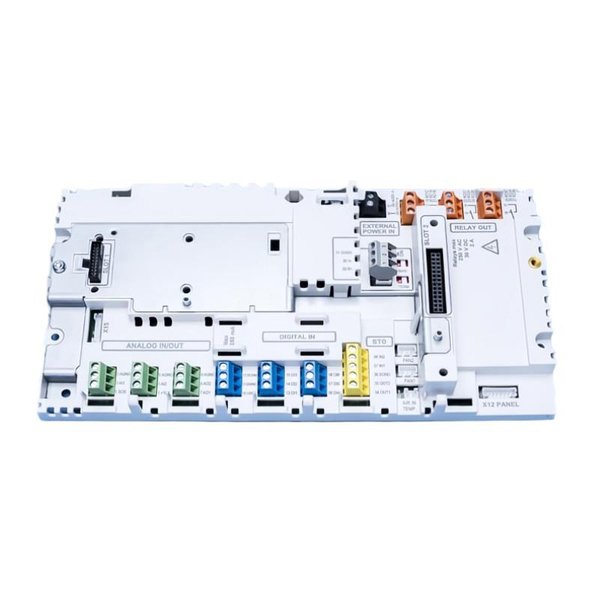

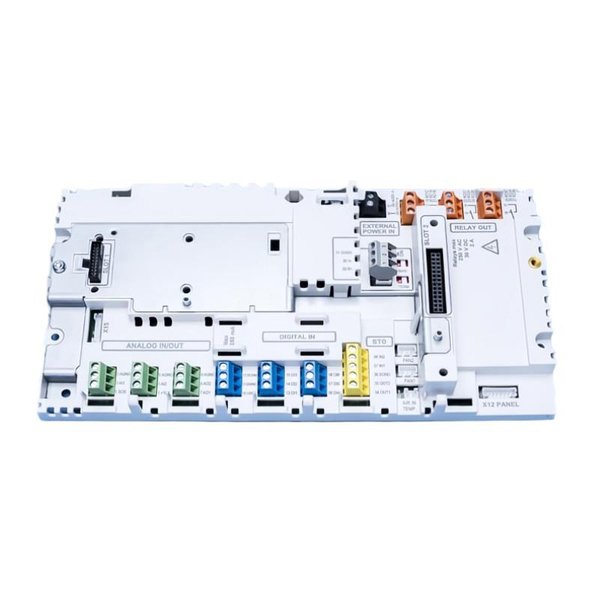

ABB CCU-24-H 3AXD50000018771 Control Unit

Manufacturer:ABB

Product Number:CCU-24-H 3AXD50000018771

Product Type:Control Unit

Origin:Sweden

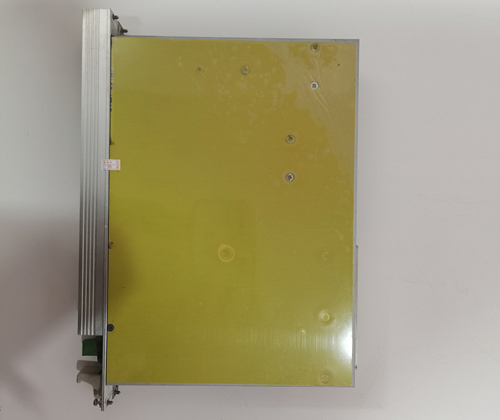

Dimensions:120 × 90 × 60 mm

Weight:0.5 kg

Views:60

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

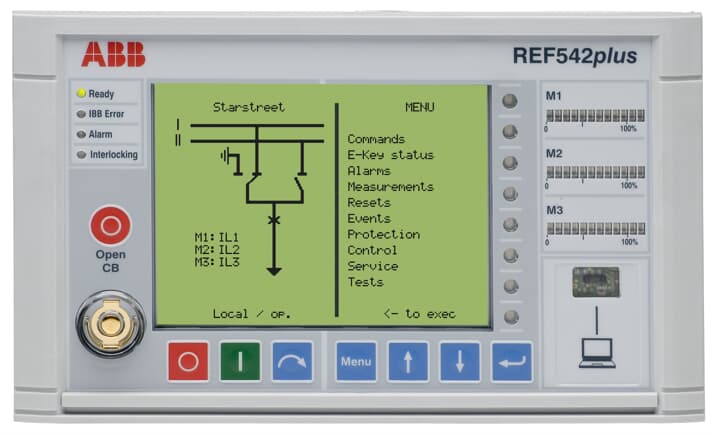

The ABB CCU-24-H 3AXD50000018771 is a high-performance control unit designed to manage and optimize the operation of ABB ACS880 frequency converters and industrial drive systems. As a core component of ABB’s advanced drive solutions, the CCU-24-H delivers fast, precise motor control, seamless integration with factory automation systems, and flexible configuration options.

Building on ABB’s robust engineering expertise, this control unit provides an enhanced CPU, expanded memory, and high-speed communication interfaces, making it suitable for demanding applications such as high-speed manufacturing lines, precision motion control, and energy-intensive process industries. With its advanced diagnostics and support for predictive maintenance, the CCU-24-H enables plant operators to improve productivity, reduce downtime, and achieve optimal performance across their drive systems.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | CCU-24-H 3AXD50000018771 |

| Product Type | Advanced Control Unit for ABB ACS880 Drives |

| Processor | Dual-core ARM Cortex CPU with enhanced clock speed |

| Processing Speed | 1.2 GHz |

| Internal Memory | 1 GB RAM, 512 MB Flash |

| Supported Drives | ACS880-01, ACS880-07, ACS880-104, DCS880 |

| Digital Inputs | 6 configurable DI |

| Digital Outputs | 4 configurable DO |

| Analog Inputs | 2 AI (configurable voltage/current) |

| Analog Outputs | 2 AO (configurable voltage/current) |

| Communication Interfaces | Profinet, EtherNet/IP, Modbus TCP, Profibus DP, CANopen |

| Fieldbus Protocol Support | Yes – multi-protocol support |

| Power Supply Voltage | 24 VDC ±10% |

| Operating Temperature | -10 °C to +50 °C |

| Storage Temperature | -25 °C to +70 °C |

| Humidity | 5% to 95% RH, non-condensing |

| Shock & Vibration Resistance | IEC 60068-2-6 / IEC 60068-2-27 compliant |

| Ingress Protection (IP) Rating | IP20 |

| Certifications | CE, UL, RoHS, EN 61800-5-1, EN 61800-3 |

| Mounting Method | DIN rail or integrated drive mount |

| Weight | 0.5 kg |

| Dimensions (H x W x D) | 120 × 90 × 60 mm |

Applications

The CCU-24-H Control Unit is engineered for use in a wide variety of complex industrial environments, particularly where high-speed, high-precision motor control is required:

-

Automotive Manufacturing

For robotic assembly lines, conveyor systems, and paint shops requiring synchronized, accurate motor control.

-

Pulp & Paper Processing

Regulates large paper machines, drying sections, and winders with dynamic speed adjustments.

-

Metals Industry

Controls rolling mills, shears, and hoisting systems with fast response and precise torque control.

-

Water & Wastewater Treatment

Optimizes pump stations, blowers, and mixers for efficient process control and reduced energy use.

-

Oil & Gas Processing

Ensures stable operation of large compressors, pumps, and fans in harsh industrial environments.

-

Renewable Energy Systems

Manages generator control, wind turbine drives, and hydroelectric plant systems.

-

Marine Applications

Provides control for propulsion systems, thrusters, and winch drives.

Product Advantages

-

Superior Performance

Enhanced dual-core ARM processor ensures ultra-fast control cycles and highly responsive motor operation.

-

Comprehensive Communication

Supports EtherNet/IP, Profinet, Profibus DP, CANopen, Modbus TCP, allowing easy integration into modern Industry 4.0 environments.

-

Scalable & Flexible

Easily adapts to single-drive or multi-drive systems with scalable architecture.

-

Advanced Diagnostics & Predictive Maintenance

Built-in intelligent diagnostics support predictive maintenance, helping to reduce unplanned downtime and extending system life.

-

Enhanced I/O Capacity

Rich set of configurable digital and analog I/Os provides broad flexibility in system configuration and device interfacing.

-

Robust & Reliable

Rugged industrial design meets international standards for vibration, temperature, and EMC immunity.

-

Energy-Efficient Control

Optimized algorithms ensure precise torque and speed control, improving energy efficiency and reducing operating costs.

-

Global Compliance

Fully compliant with CE, UL, and RoHS standards, making it suitable for worldwide deployments.

-

Easy Installation & Commissioning

Seamless plug-and-play compatibility with ABB ACS880 drives shortens commissioning time and simplifies maintenance.

FAQ

-

What is the primary function of the CCU-24-H Control Unit?

It serves as the main processing and communication module for ABB ACS880 drives, providing high-speed motor control and system integration.

-

What type of applications is the CCU-24-H designed for?

It is designed for high-performance industrial automation, such as metal processing, automotive production, paper manufacturing, and energy systems.

-

How does the CCU-24-H improve energy efficiency?

It optimizes torque and speed control using advanced algorithms, helping to reduce power consumption and improve system efficiency.

-

Can the CCU-24-H be used in multi-drive configurations?

Yes, it supports both single-drive and multi-drive systems through advanced architecture and flexible I/O configurations.

-

Does this module support integration with PLC or DCS systems?

Yes, it offers full compatibility with PLC, DCS, and SCADA systems via multiple industrial protocols such as EtherNet/IP, Profinet, Profibus DP, and CANopen.

-

What is the maximum power handling capability supported by drives controlled with the CCU-24-H?

It is used in drive systems that can manage power ratings up to 710 kW or higher depending on the configuration.

-

Is the CCU-24-H suitable for safety-critical applications?

Yes, it is designed with high reliability and can be configured for safety functions when used with appropriate ABB safety modules.

-

How is firmware updated for the CCU-24-H?

Firmware can be updated via ABB Drive Composer software or other ABB tools, ensuring secure and seamless updates.

-

Does the unit provide built-in predictive maintenance functions?

Yes, the CCU-24-H has advanced monitoring and supports predictive maintenance through ABB’s monitoring and diagnostic tools.

-

What environmental conditions can the CCU-24-H operate in?

It operates in temperatures from -10 °C to +50 °C and is compliant with industrial vibration and EMC standards, ensuring robust performance in harsh environments.

ABB CCU-24-H 3AXD50000018771 Control Unit

Manufacturer:ABB

Product Number:CCU-24-H 3AXD50000018771

Product Type:Control Unit

Origin:Sweden

Dimensions:120 × 90 × 60 mm

Weight:0.5 kg

Views:60

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB CCU-24-H 3AXD50000018771 is a high-performance control unit designed to manage and optimize the operation of ABB ACS880 frequency converters and industrial drive systems. As a core component of ABB’s advanced drive solutions, the CCU-24-H delivers fast, precise motor control, seamless integration with factory automation systems, and flexible configuration options.

Building on ABB’s robust engineering expertise, this control unit provides an enhanced CPU, expanded memory, and high-speed communication interfaces, making it suitable for demanding applications such as high-speed manufacturing lines, precision motion control, and energy-intensive process industries. With its advanced diagnostics and support for predictive maintenance, the CCU-24-H enables plant operators to improve productivity, reduce downtime, and achieve optimal performance across their drive systems.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | CCU-24-H 3AXD50000018771 |

| Product Type | Advanced Control Unit for ABB ACS880 Drives |

| Processor | Dual-core ARM Cortex CPU with enhanced clock speed |

| Processing Speed | 1.2 GHz |

| Internal Memory | 1 GB RAM, 512 MB Flash |

| Supported Drives | ACS880-01, ACS880-07, ACS880-104, DCS880 |

| Digital Inputs | 6 configurable DI |

| Digital Outputs | 4 configurable DO |

| Analog Inputs | 2 AI (configurable voltage/current) |

| Analog Outputs | 2 AO (configurable voltage/current) |

| Communication Interfaces | Profinet, EtherNet/IP, Modbus TCP, Profibus DP, CANopen |

| Fieldbus Protocol Support | Yes – multi-protocol support |

| Power Supply Voltage | 24 VDC ±10% |

| Operating Temperature | -10 °C to +50 °C |

| Storage Temperature | -25 °C to +70 °C |

| Humidity | 5% to 95% RH, non-condensing |

| Shock & Vibration Resistance | IEC 60068-2-6 / IEC 60068-2-27 compliant |

| Ingress Protection (IP) Rating | IP20 |

| Certifications | CE, UL, RoHS, EN 61800-5-1, EN 61800-3 |

| Mounting Method | DIN rail or integrated drive mount |

| Weight | 0.5 kg |

| Dimensions (H x W x D) | 120 × 90 × 60 mm |

Applications

The CCU-24-H Control Unit is engineered for use in a wide variety of complex industrial environments, particularly where high-speed, high-precision motor control is required:

-

Automotive Manufacturing

For robotic assembly lines, conveyor systems, and paint shops requiring synchronized, accurate motor control.

-

Pulp & Paper Processing

Regulates large paper machines, drying sections, and winders with dynamic speed adjustments.

-

Metals Industry

Controls rolling mills, shears, and hoisting systems with fast response and precise torque control.

-

Water & Wastewater Treatment

Optimizes pump stations, blowers, and mixers for efficient process control and reduced energy use.

-

Oil & Gas Processing

Ensures stable operation of large compressors, pumps, and fans in harsh industrial environments.

-

Renewable Energy Systems

Manages generator control, wind turbine drives, and hydroelectric plant systems.

-

Marine Applications

Provides control for propulsion systems, thrusters, and winch drives.

Product Advantages

-

Superior Performance

Enhanced dual-core ARM processor ensures ultra-fast control cycles and highly responsive motor operation.

-

Comprehensive Communication

Supports EtherNet/IP, Profinet, Profibus DP, CANopen, Modbus TCP, allowing easy integration into modern Industry 4.0 environments.

-

Scalable & Flexible

Easily adapts to single-drive or multi-drive systems with scalable architecture.

-

Advanced Diagnostics & Predictive Maintenance

Built-in intelligent diagnostics support predictive maintenance, helping to reduce unplanned downtime and extending system life.

-

Enhanced I/O Capacity

Rich set of configurable digital and analog I/Os provides broad flexibility in system configuration and device interfacing.

-

Robust & Reliable

Rugged industrial design meets international standards for vibration, temperature, and EMC immunity.

-

Energy-Efficient Control

Optimized algorithms ensure precise torque and speed control, improving energy efficiency and reducing operating costs.

-

Global Compliance

Fully compliant with CE, UL, and RoHS standards, making it suitable for worldwide deployments.

-

Easy Installation & Commissioning

Seamless plug-and-play compatibility with ABB ACS880 drives shortens commissioning time and simplifies maintenance.

FAQ

-

What is the primary function of the CCU-24-H Control Unit?

It serves as the main processing and communication module for ABB ACS880 drives, providing high-speed motor control and system integration.

-

What type of applications is the CCU-24-H designed for?

It is designed for high-performance industrial automation, such as metal processing, automotive production, paper manufacturing, and energy systems.

-

How does the CCU-24-H improve energy efficiency?

It optimizes torque and speed control using advanced algorithms, helping to reduce power consumption and improve system efficiency.

-

Can the CCU-24-H be used in multi-drive configurations?

Yes, it supports both single-drive and multi-drive systems through advanced architecture and flexible I/O configurations.

-

Does this module support integration with PLC or DCS systems?

Yes, it offers full compatibility with PLC, DCS, and SCADA systems via multiple industrial protocols such as EtherNet/IP, Profinet, Profibus DP, and CANopen.

-

What is the maximum power handling capability supported by drives controlled with the CCU-24-H?

It is used in drive systems that can manage power ratings up to 710 kW or higher depending on the configuration.

-

Is the CCU-24-H suitable for safety-critical applications?

Yes, it is designed with high reliability and can be configured for safety functions when used with appropriate ABB safety modules.

-

How is firmware updated for the CCU-24-H?

Firmware can be updated via ABB Drive Composer software or other ABB tools, ensuring secure and seamless updates.

-

Does the unit provide built-in predictive maintenance functions?

Yes, the CCU-24-H has advanced monitoring and supports predictive maintenance through ABB’s monitoring and diagnostic tools.

-

What environmental conditions can the CCU-24-H operate in?

It operates in temperatures from -10 °C to +50 °C and is compliant with industrial vibration and EMC standards, ensuring robust performance in harsh environments.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...