Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

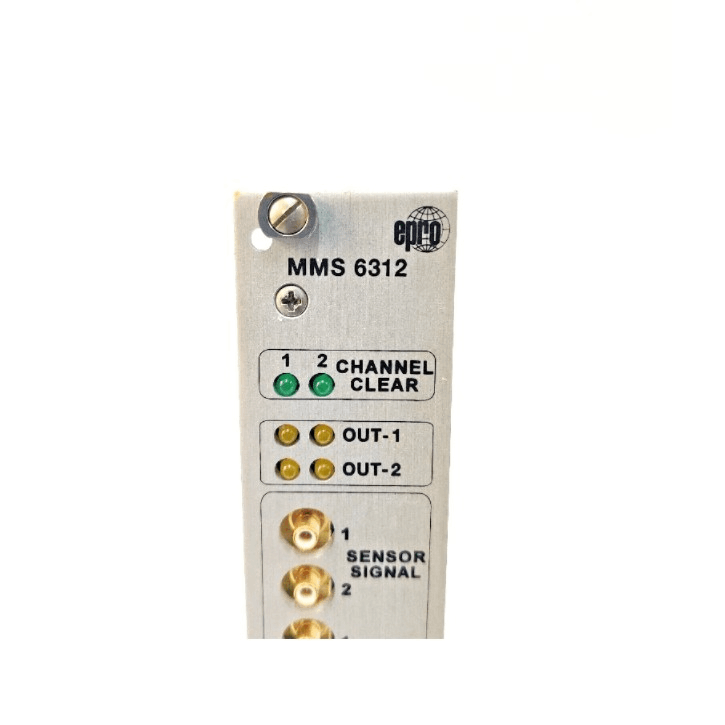

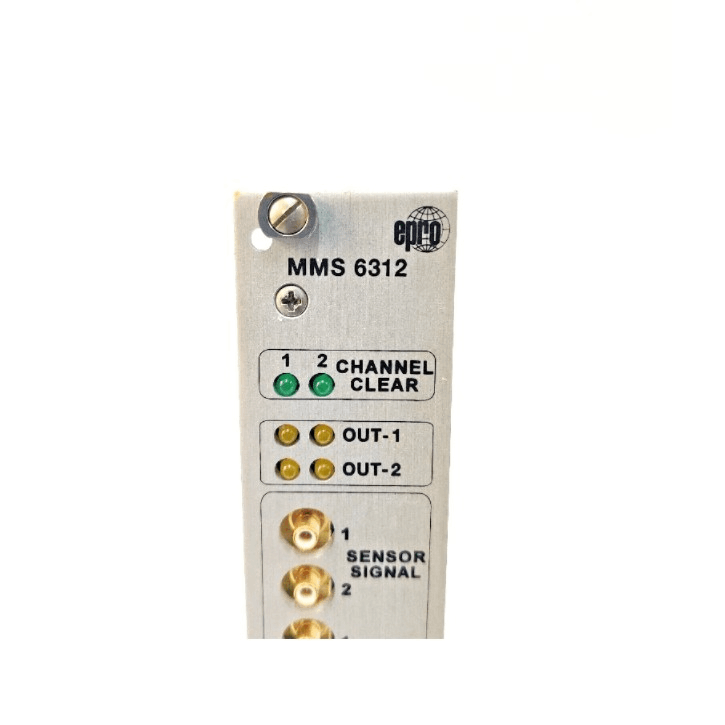

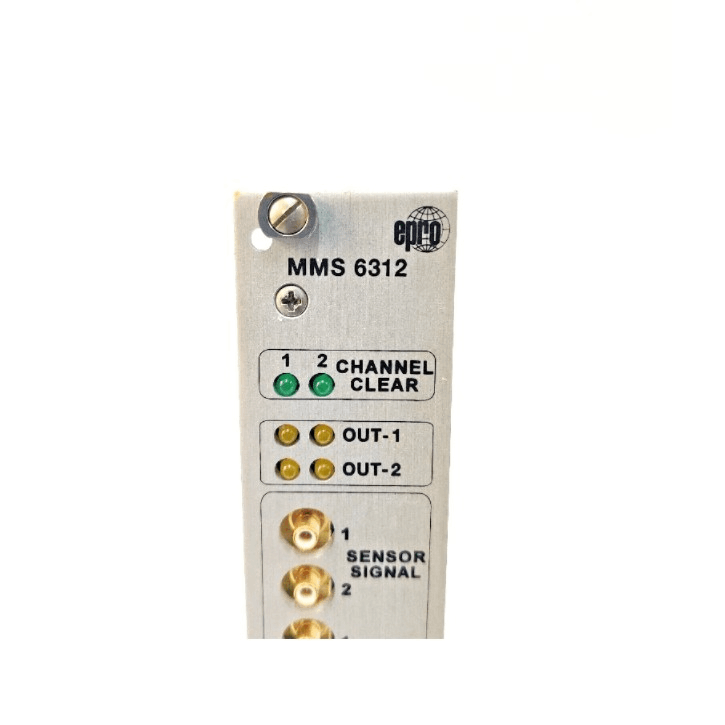

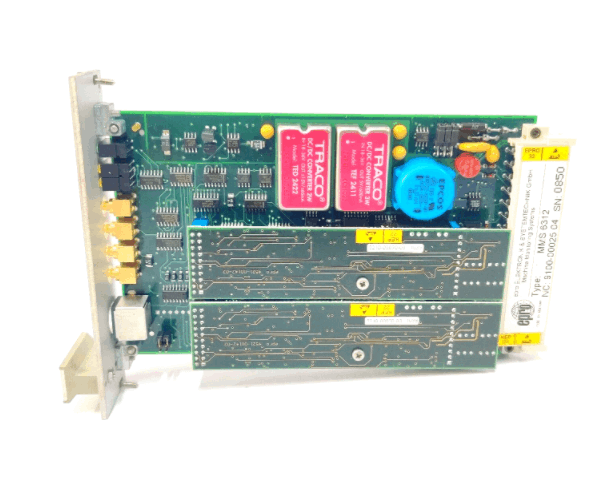

Epro MMS6312 Dual Channel Rotational Speed Monitor

Item Number: MMS6312

Brand: EPRO

Lead Time: In stock

Description: Dual Channel Rotational Speed Monitor

Payment: T/T

Product Description

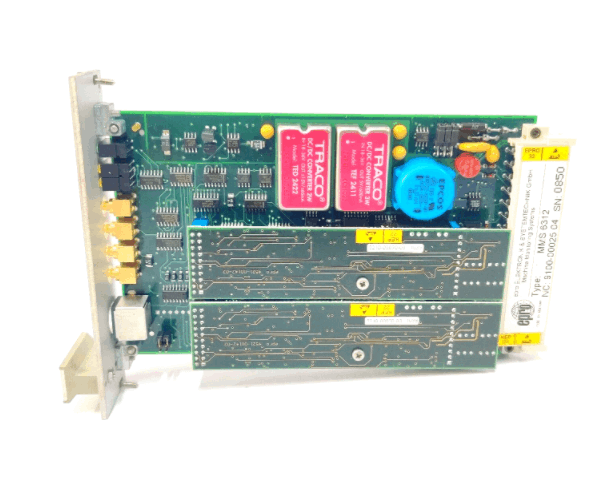

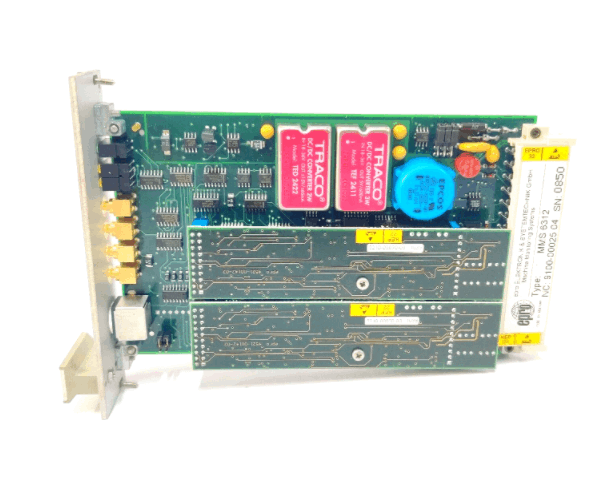

EPRO MMS6312 Dual Channel Rotational Speed Monitor, part of the MMS 6000 system, is primarily used to measure shaft speed. It utilizes the output of a pulse sensor in conjunction with a trigger wheel to achieve measurement functionality. The module's two channels can be used individually or in combination. It can be used for surge monitoring and anti-reverse rotation protection.

Function & Features

- Dual-Channel Configuration: The MMS6312 can independently measure the speed of two axes, the standstill of two axes, and key pulses with a trigger marker (including phase relationship) for each axis. It can also be used in combination to detect the rotation direction of a single axis or the speed difference between two axes. It can also be used as part of a multi-channel or redundant system.

- Sensor Interface: The MMS6312 supports eddy-current sensors (PR 6422/PR 6425 series + CON connector) and can also be used with PR 9376/.. and PR 6453/.. pulse sensors.

- Remote Configuration: RS485 interface (for connection to the EPRO MMS 6850 system).

Specifications

| Parameter |

Details |

|

Model |

MMS6312 |

|

Input resistance |

> 100 kOhm |

|

Input voltage range |

0...+ or -27.3 V dc |

|

Max. permissible input voltage range |

0...30 V |

|

Input frequency range |

0...20000 Hz |

|

Minimum input level for automatic tracing (Automatic or manual trigger level adjustment) |

2 V |

|

Width |

30.0 mm (6 TE) |

|

Height |

128.4 mm (3 HE) |

|

Length |

160.0 mm |

|

Net weight |

app. 320 g |

Epro MMS6312 Dual Channel Rotational Speed Monitor

Item Number: MMS6312

Brand: EPRO

Lead Time: In stock

Description: Dual Channel Rotational Speed Monitor

Payment: T/T

Product Description

EPRO MMS6312 Dual Channel Rotational Speed Monitor, part of the MMS 6000 system, is primarily used to measure shaft speed. It utilizes the output of a pulse sensor in conjunction with a trigger wheel to achieve measurement functionality. The module's two channels can be used individually or in combination. It can be used for surge monitoring and anti-reverse rotation protection.

Function & Features

- Dual-Channel Configuration: The MMS6312 can independently measure the speed of two axes, the standstill of two axes, and key pulses with a trigger marker (including phase relationship) for each axis. It can also be used in combination to detect the rotation direction of a single axis or the speed difference between two axes. It can also be used as part of a multi-channel or redundant system.

- Sensor Interface: The MMS6312 supports eddy-current sensors (PR 6422/PR 6425 series + CON connector) and can also be used with PR 9376/.. and PR 6453/.. pulse sensors.

- Remote Configuration: RS485 interface (for connection to the EPRO MMS 6850 system).

Specifications

| Parameter |

Details |

|

Model |

MMS6312 |

|

Input resistance |

> 100 kOhm |

|

Input voltage range |

0...+ or -27.3 V dc |

|

Max. permissible input voltage range |

0...30 V |

|

Input frequency range |

0...20000 Hz |

|

Minimum input level for automatic tracing (Automatic or manual trigger level adjustment) |

2 V |

|

Width |

30.0 mm (6 TE) |

|

Height |

128.4 mm (3 HE) |

|

Length |

160.0 mm |

|

Net weight |

app. 320 g |

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...