Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

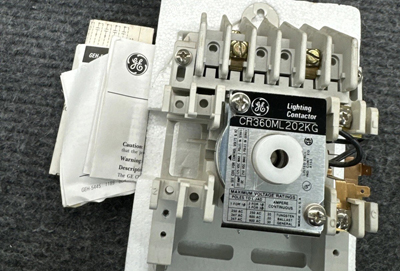

General Electric IS215UCVHM06A Universal Controller Module

Manufacturer:GE

Product Number:IS215UCVHM06A

Product Type:Universal Controller Module

Origin:USA

Dimensions:110 x 90 x 30 mm

Weight:1.2 kg

Views:37

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

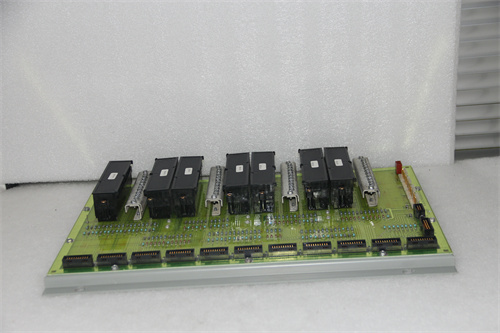

The GE IS215UCVHM06A Universal Controller Module is a state-of-the-art, industrial-grade controller designed for use in GE Mark VIe and Mark VI turbine and process control platforms, which are part of the globally respected GE Speedtronic™ family of automation solutions.

Engineered for flexible and reliable control, the IS215UCVHM06A performs as a high-speed, real-time controller in gas and steam turbine systems, balance of plant (BoP) applications, and a wide array of industrial automation processes.

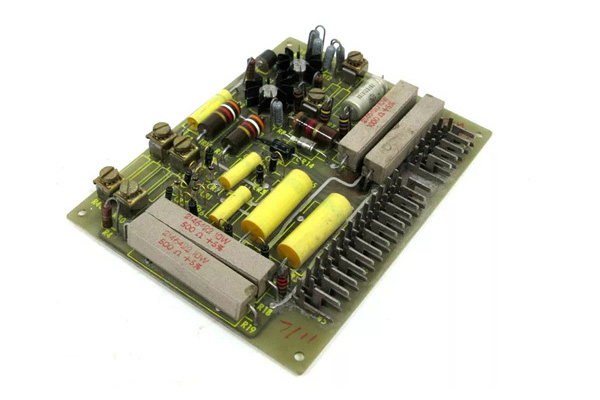

Equipped with an advanced CPU, large SDRAM and Flash memory, and a deterministic real-time embedded operating system, the module ensures fast control loop execution, dependable communications, and consistent, low-latency performance. The IS215UCVHM06A’s single-slot VMEbus architecture allows for easy integration into GE Mark VI / VIe racks and supports both standalone and redundant control configurations.

Its rugged design and compliance with industrial vibration, shock, and environmental standards make the module perfectly suited for mission-critical applications such as power generation plants, oil & gas production, chemical facilities, and heavy manufacturing.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | GE IS215UCVHM06A Universal Controller Module |

| Part Number | IS215UCVHM06A |

| System Compatibility | GE Mark VI, Mark VIe, Speedtronic™ |

| Module Type | Universal Controller (UCV) |

| CPU | High-performance industrial CPU |

| Memory | SDRAM (volatile), Flash (non-volatile) |

| Operating System | Deterministic real-time embedded OS |

| Slot Requirement | Single-slot VMEbus rack module |

| Communication Interfaces | Ethernet 10/100 Mbps, Serial, VMEbus |

| Supported Protocols | Ethernet/IP, Modbus, proprietary GE protocols |

| Control Applications | Gas/steam turbine control, BoP systems, auxiliary process control |

| Time Synchronization | GPS, NTP synchronization capable |

| Redundancy Support | Yes — supports redundant controller configurations |

| Data Logging | Onboard data logging supported |

| Diagnostics | Self-diagnostics and status reporting |

| Firmware Upgrade | Field upgradeable via Ethernet |

| Power Supply | 5 VDC supplied by VME backplane |

| Power Consumption | Approx. 20 W typical |

| Operating Temperature Range | -30°C to +65°C (-22°F to +149°F) |

| Storage Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Relative Humidity Range | 5% to 95% RH (non-condensing) |

| Vibration Compliance | IEC 60068-2-6 |

| Shock Compliance | IEC 60068-2-27 |

| PCB Protection | Conformal coating for harsh environments |

| Dimensions (H x W x D) | 110 x 90 x 30 mm |

| Weight | 1.2 kg |

| Mounting Method | Single-slot VME rack mount |

| Certifications | CE, UL, CSA, RoHS compliant |

Applications

-

Primary controller in gas turbine control systems

-

Steam turbine automation and performance control

-

Control for balance of plant (BoP) systems

-

Real-time process control in power generation stations

-

Distributed control system (DCS) for oil & gas platforms

-

Process optimization in chemical processing plants

-

Advanced automation in marine propulsion and energy systems

-

Auxiliary system control for industrial manufacturing plants

-

Process monitoring in mining and materials industries

-

General-purpose high-speed industrial automation applications

Product Advantages

-

High-performance CPU: Ensures fast, reliable control and communications

-

Real-time OS: Guarantees deterministic response and low latency

-

Modular design: Compatible with GE Mark VI/VIe control architecture

-

Flexible deployment: Supports both standalone and redundant configurations

-

Industrial ruggedness: Built to withstand vibration, shock, and extreme conditions

-

Space-saving: Compact, single-slot VME form factor

-

Comprehensive diagnostics: Enables predictive maintenance and faster troubleshooting

-

Global compliance: Certified for worldwide deployment with CE, UL, CSA, and RoHS approvals

-

Low maintenance: Supports firmware updates in the field

-

Longevity: Designed for continuous 24/7 industrial operation

Frequently Asked Questions (FAQ)

-

How does the IS215UCVHM06A enhance turbine performance?

The module delivers high-speed control and precise execution of turbine control logic, enabling better performance, efficiency, and reliability of gas and steam turbines.

-

What is the role of memory in the IS215UCVHM06A?

It uses volatile SDRAM for fast control processing and non-volatile flash memory to store critical configuration data, ensuring seamless system startup and recovery.

-

How does this module interact with external devices?

Through Ethernet, serial, and VMEbus interfaces, the module communicates with other controllers, HMIs, field devices, and plant networks.

-

What type of real-time control applications is this module suitable for?

It is ideal for mission-critical process control, including turbine automation, power plant auxiliary system control, and real-time manufacturing processes.

-

How is the module maintained in the field?

It supports remote diagnostics and field firmware upgrades, minimizing downtime and simplifying long-term maintenance.

-

What redundancy features does the IS215UCVHM06A offer?

The module supports hot backup and seamless failover when deployed in redundant configurations, ensuring uninterrupted control during hardware failures.

-

How does the module contribute to predictive maintenance?

Built-in diagnostic tools and data logging capabilities provide early warning of potential faults, enabling proactive maintenance scheduling.

-

What is the benefit of using VMEbus architecture?

VMEbus architecture offers high-speed, deterministic communications between modules, which is essential for real-time control in complex automation systems.

-

Can the IS215UCVHM06A operate in harsh industrial environments?

Yes,it is designed to withstand vibration, shock, temperature extremes, and humidity, with a conformal-coated PCB for extra protection.

-

What are the key certifications that ensure global usability?

The module is CE, UL, CSA, and RoHS compliant, making it suitable for deployment in plants and facilities worldwide.

General Electric IS215UCVHM06A Universal Controller Module

Manufacturer:GE

Product Number:IS215UCVHM06A

Product Type:Universal Controller Module

Origin:USA

Dimensions:110 x 90 x 30 mm

Weight:1.2 kg

Views:37

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS215UCVHM06A Universal Controller Module is a state-of-the-art, industrial-grade controller designed for use in GE Mark VIe and Mark VI turbine and process control platforms, which are part of the globally respected GE Speedtronic™ family of automation solutions.

Engineered for flexible and reliable control, the IS215UCVHM06A performs as a high-speed, real-time controller in gas and steam turbine systems, balance of plant (BoP) applications, and a wide array of industrial automation processes.

Equipped with an advanced CPU, large SDRAM and Flash memory, and a deterministic real-time embedded operating system, the module ensures fast control loop execution, dependable communications, and consistent, low-latency performance. The IS215UCVHM06A’s single-slot VMEbus architecture allows for easy integration into GE Mark VI / VIe racks and supports both standalone and redundant control configurations.

Its rugged design and compliance with industrial vibration, shock, and environmental standards make the module perfectly suited for mission-critical applications such as power generation plants, oil & gas production, chemical facilities, and heavy manufacturing.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | GE IS215UCVHM06A Universal Controller Module |

| Part Number | IS215UCVHM06A |

| System Compatibility | GE Mark VI, Mark VIe, Speedtronic™ |

| Module Type | Universal Controller (UCV) |

| CPU | High-performance industrial CPU |

| Memory | SDRAM (volatile), Flash (non-volatile) |

| Operating System | Deterministic real-time embedded OS |

| Slot Requirement | Single-slot VMEbus rack module |

| Communication Interfaces | Ethernet 10/100 Mbps, Serial, VMEbus |

| Supported Protocols | Ethernet/IP, Modbus, proprietary GE protocols |

| Control Applications | Gas/steam turbine control, BoP systems, auxiliary process control |

| Time Synchronization | GPS, NTP synchronization capable |

| Redundancy Support | Yes — supports redundant controller configurations |

| Data Logging | Onboard data logging supported |

| Diagnostics | Self-diagnostics and status reporting |

| Firmware Upgrade | Field upgradeable via Ethernet |

| Power Supply | 5 VDC supplied by VME backplane |

| Power Consumption | Approx. 20 W typical |

| Operating Temperature Range | -30°C to +65°C (-22°F to +149°F) |

| Storage Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Relative Humidity Range | 5% to 95% RH (non-condensing) |

| Vibration Compliance | IEC 60068-2-6 |

| Shock Compliance | IEC 60068-2-27 |

| PCB Protection | Conformal coating for harsh environments |

| Dimensions (H x W x D) | 110 x 90 x 30 mm |

| Weight | 1.2 kg |

| Mounting Method | Single-slot VME rack mount |

| Certifications | CE, UL, CSA, RoHS compliant |

Applications

-

Primary controller in gas turbine control systems

-

Steam turbine automation and performance control

-

Control for balance of plant (BoP) systems

-

Real-time process control in power generation stations

-

Distributed control system (DCS) for oil & gas platforms

-

Process optimization in chemical processing plants

-

Advanced automation in marine propulsion and energy systems

-

Auxiliary system control for industrial manufacturing plants

-

Process monitoring in mining and materials industries

-

General-purpose high-speed industrial automation applications

Product Advantages

-

High-performance CPU: Ensures fast, reliable control and communications

-

Real-time OS: Guarantees deterministic response and low latency

-

Modular design: Compatible with GE Mark VI/VIe control architecture

-

Flexible deployment: Supports both standalone and redundant configurations

-

Industrial ruggedness: Built to withstand vibration, shock, and extreme conditions

-

Space-saving: Compact, single-slot VME form factor

-

Comprehensive diagnostics: Enables predictive maintenance and faster troubleshooting

-

Global compliance: Certified for worldwide deployment with CE, UL, CSA, and RoHS approvals

-

Low maintenance: Supports firmware updates in the field

-

Longevity: Designed for continuous 24/7 industrial operation

Frequently Asked Questions (FAQ)

-

How does the IS215UCVHM06A enhance turbine performance?

The module delivers high-speed control and precise execution of turbine control logic, enabling better performance, efficiency, and reliability of gas and steam turbines.

-

What is the role of memory in the IS215UCVHM06A?

It uses volatile SDRAM for fast control processing and non-volatile flash memory to store critical configuration data, ensuring seamless system startup and recovery.

-

How does this module interact with external devices?

Through Ethernet, serial, and VMEbus interfaces, the module communicates with other controllers, HMIs, field devices, and plant networks.

-

What type of real-time control applications is this module suitable for?

It is ideal for mission-critical process control, including turbine automation, power plant auxiliary system control, and real-time manufacturing processes.

-

How is the module maintained in the field?

It supports remote diagnostics and field firmware upgrades, minimizing downtime and simplifying long-term maintenance.

-

What redundancy features does the IS215UCVHM06A offer?

The module supports hot backup and seamless failover when deployed in redundant configurations, ensuring uninterrupted control during hardware failures.

-

How does the module contribute to predictive maintenance?

Built-in diagnostic tools and data logging capabilities provide early warning of potential faults, enabling proactive maintenance scheduling.

-

What is the benefit of using VMEbus architecture?

VMEbus architecture offers high-speed, deterministic communications between modules, which is essential for real-time control in complex automation systems.

-

Can the IS215UCVHM06A operate in harsh industrial environments?

Yes,it is designed to withstand vibration, shock, temperature extremes, and humidity, with a conformal-coated PCB for extra protection.

-

What are the key certifications that ensure global usability?

The module is CE, UL, CSA, and RoHS compliant, making it suitable for deployment in plants and facilities worldwide.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...