Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

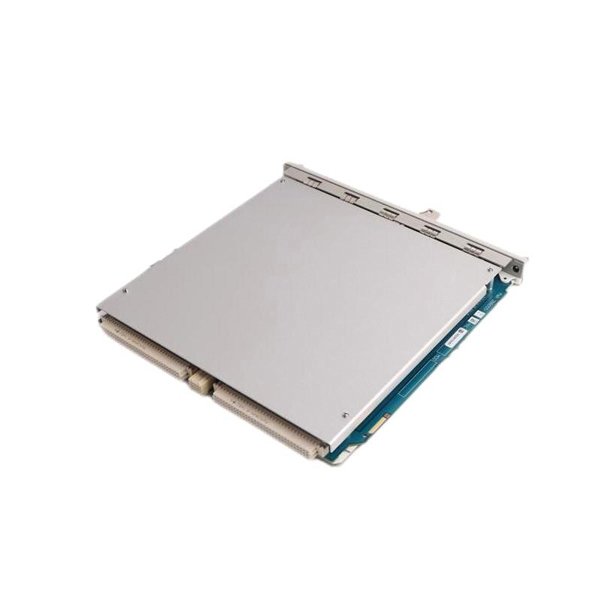

Bently Nevada 3500/22M 288055-01 Transient Data Interface Module

Manufacturer:Bently Nevada

Product Number:3500/22M 288055-01

Product Type:Transient Data Interface Module

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:120

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/22M 288055-01 Transient Data Interface (TDI) Module is an integral component of the Bently Nevada 3500 Machinery Protection and Condition Monitoring System. Designed to serve as the primary communication interface between the 3500 rack and external software platforms such as System 1®, the 22M TDI module collects and transmits static, dynamic, and transient data from all modules in the rack.

This module combines the functionality of the older 3500/20 Rack Interface Module and a Communication Processor Module into a single high-performance unit. With its modular design, the 3500/22M supports both transient data and static values and plays a critical role in real-time diagnostics and post-event analysis. Equipped with dual-redundant Ethernet ports and buffered output interfaces, the 22M TDI ensures robust data communication with minimal latency and high reliability across a wide range of industrial machinery monitoring applications.

Product Specifications

| Parameter | Specification |

| Model Number | 3500/22M |

| Part Number | 288055-01 |

| Function | Transient Data Interface Module |

| System Compatibility | Bently Nevada 3500 Series Rack |

| Communication Interfaces | Dual Ethernet ports (100Base-TX), RS232/485 |

| Protocols Supported | Proprietary protocol for System 1® connectivity |

| Data Types Transmitted | Static data, dynamic vibration data, transient data |

| Buffered Output Terminals | Yes, for diagnostic access via BNC connectors |

| Data Rate | Up to 100 Mbps Ethernet |

| Redundancy Support | Yes, via redundant TDI configuration |

| Configuration Interface | 3500/01 Rack Configuration Software |

| Power Consumption | 4.0 W (typical) |

| Operating Temperature | –30°C to +65°C |

| Storage Temperature | –40°C to +85°C |

| Humidity Range | 0% to 95% non-condensing |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Mounting | Plugs directly into the 3500 rack |

| Firmware Upgradable | Yes, via System 1® and rack config software |

Applications

-

Transient Data Acquisition

-

Captures and stores transient vibration events such as startups, shutdowns, trips, and other anomalies.

-

-

Integration with System 1®

-

Seamless data streaming into Bently Nevada’s predictive analytics platform.

-

-

Plantwide Monitoring Infrastructure

-

Acts as a centralized data gateway across multiple machinery systems.

-

-

Diagnostics & Root Cause Analysis

-

Ideal for engineers seeking detailed, timestamped event data.

-

-

Critical Asset Protection

-

Used across oil & gas, petrochemical, power generation, marine, and mining industries.

-

Advantages

-

Combined Functionality

-

Reduces hardware requirements by combining rack interface and communication into a single module.

-

-

High-Speed Data Capture

-

Enables advanced monitoring with real-time dynamic and transient data.

-

-

Redundancy Ready

-

Supports dual TDI installation for fault-tolerant operation.

-

-

Seamless Integration

-

Plug-and-play compatibility with Bently Nevada’s System 1® software.

-

-

Improved Diagnostic Capability

-

Enables pre- and post-fault waveform analysis, helping avoid unplanned downtime.

-

-

Firmware Upgrade Support

-

Ensures long-term support and scalability for future features.

-

-

Rugged and Reliable

-

Engineered for harsh industrial environments with high shock and vibration tolerance.

-

-

-

Easy to replace or upgrade without rack downtime or re-cabling.

-

FAQ

-

Q: What’s the main role of the 3500/22M in the 3500 rack?

A: It acts as the primary interface for all communication between the rack and external monitoring systems like System 1®.

-

Q: Can the 3500/22M operate independently without System 1®?

A: While it can collect data, its full potential is realized when used with System 1® for visualization and diagnostics.

-

Q: Is the 3500/22M hot-swappable?

A: Yes, it can be replaced without removing power from the entire rack.

-

Q: How does the TDI support redundant configurations?

A: Dual 22M modules can be installed for automatic failover, ensuring uninterrupted operation.

-

Q: Does it require a special software to configure?

A: Yes, configuration is done via Bently Nevada’s 3500/01 Rack Configuration Software.

-

Q: Can this module handle high vibration environments?

A: Absolutely. It is designed for industrial-grade environments including turbine enclosures.

-

Q: What type of transient data can it capture?

A: Startups, shutdowns, machine trips, surge events, and speed changes.

-

Q: How is the data transferred to external systems?

A: Via dual Ethernet ports using Bently Nevada’s proprietary protocol.

-

Q: Does it store data locally?

A: No, it streams data in real time to external systems for storage and analysis.

-

Q: What’s the difference between 3500/22 and 3500/22M?

A: The “M” version provides enhanced features, faster data throughput, and improved diagnostic integration.

Bently Nevada 3500/22M 288055-01 Transient Data Interface Module

Manufacturer:Bently Nevada

Product Number:3500/22M 288055-01

Product Type:Transient Data Interface Module

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:120

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/22M 288055-01 Transient Data Interface (TDI) Module is an integral component of the Bently Nevada 3500 Machinery Protection and Condition Monitoring System. Designed to serve as the primary communication interface between the 3500 rack and external software platforms such as System 1®, the 22M TDI module collects and transmits static, dynamic, and transient data from all modules in the rack.

This module combines the functionality of the older 3500/20 Rack Interface Module and a Communication Processor Module into a single high-performance unit. With its modular design, the 3500/22M supports both transient data and static values and plays a critical role in real-time diagnostics and post-event analysis. Equipped with dual-redundant Ethernet ports and buffered output interfaces, the 22M TDI ensures robust data communication with minimal latency and high reliability across a wide range of industrial machinery monitoring applications.

Product Specifications

| Parameter | Specification |

| Model Number | 3500/22M |

| Part Number | 288055-01 |

| Function | Transient Data Interface Module |

| System Compatibility | Bently Nevada 3500 Series Rack |

| Communication Interfaces | Dual Ethernet ports (100Base-TX), RS232/485 |

| Protocols Supported | Proprietary protocol for System 1® connectivity |

| Data Types Transmitted | Static data, dynamic vibration data, transient data |

| Buffered Output Terminals | Yes, for diagnostic access via BNC connectors |

| Data Rate | Up to 100 Mbps Ethernet |

| Redundancy Support | Yes, via redundant TDI configuration |

| Configuration Interface | 3500/01 Rack Configuration Software |

| Power Consumption | 4.0 W (typical) |

| Operating Temperature | –30°C to +65°C |

| Storage Temperature | –40°C to +85°C |

| Humidity Range | 0% to 95% non-condensing |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Mounting | Plugs directly into the 3500 rack |

| Firmware Upgradable | Yes, via System 1® and rack config software |

Applications

-

Transient Data Acquisition

-

Captures and stores transient vibration events such as startups, shutdowns, trips, and other anomalies.

-

-

Integration with System 1®

-

Seamless data streaming into Bently Nevada’s predictive analytics platform.

-

-

Plantwide Monitoring Infrastructure

-

Acts as a centralized data gateway across multiple machinery systems.

-

-

Diagnostics & Root Cause Analysis

-

Ideal for engineers seeking detailed, timestamped event data.

-

-

Critical Asset Protection

-

Used across oil & gas, petrochemical, power generation, marine, and mining industries.

-

Advantages

-

Combined Functionality

-

Reduces hardware requirements by combining rack interface and communication into a single module.

-

-

High-Speed Data Capture

-

Enables advanced monitoring with real-time dynamic and transient data.

-

-

Redundancy Ready

-

Supports dual TDI installation for fault-tolerant operation.

-

-

Seamless Integration

-

Plug-and-play compatibility with Bently Nevada’s System 1® software.

-

-

Improved Diagnostic Capability

-

Enables pre- and post-fault waveform analysis, helping avoid unplanned downtime.

-

-

Firmware Upgrade Support

-

Ensures long-term support and scalability for future features.

-

-

Rugged and Reliable

-

Engineered for harsh industrial environments with high shock and vibration tolerance.

-

-

-

Easy to replace or upgrade without rack downtime or re-cabling.

-

FAQ

-

Q: What’s the main role of the 3500/22M in the 3500 rack?

A: It acts as the primary interface for all communication between the rack and external monitoring systems like System 1®.

-

Q: Can the 3500/22M operate independently without System 1®?

A: While it can collect data, its full potential is realized when used with System 1® for visualization and diagnostics.

-

Q: Is the 3500/22M hot-swappable?

A: Yes, it can be replaced without removing power from the entire rack.

-

Q: How does the TDI support redundant configurations?

A: Dual 22M modules can be installed for automatic failover, ensuring uninterrupted operation.

-

Q: Does it require a special software to configure?

A: Yes, configuration is done via Bently Nevada’s 3500/01 Rack Configuration Software.

-

Q: Can this module handle high vibration environments?

A: Absolutely. It is designed for industrial-grade environments including turbine enclosures.

-

Q: What type of transient data can it capture?

A: Startups, shutdowns, machine trips, surge events, and speed changes.

-

Q: How is the data transferred to external systems?

A: Via dual Ethernet ports using Bently Nevada’s proprietary protocol.

-

Q: Does it store data locally?

A: No, it streams data in real time to external systems for storage and analysis.

-

Q: What’s the difference between 3500/22 and 3500/22M?

A: The “M” version provides enhanced features, faster data throughput, and improved diagnostic integration.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...