Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

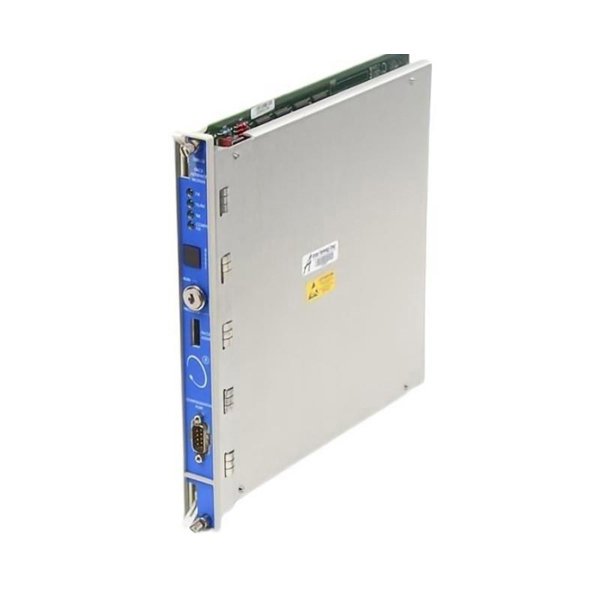

Bently Nevada 3500/22M 138607-01A Transient Data Interface Module

Manufacturer:Bently Nevada

Product Number:3500/22M 138607-01A

Product Type:Transient Data Interface Module

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/22M 138607-01A Transient Data Interface Module is an essential component of the 3500 Machinery Protection System. It acts as the primary communication hub between the rack and the external condition monitoring software, notably System 1®. This advanced module consolidates the functions of the Rack Interface Module (RIM) and transient data capture, enabling the system to collect, process, and transmit both steady-state and transient data effectively.

Designed for installation in Slot 1 of the 3500 rack, the 3500/22M 138607-01A supports high-speed Ethernet and serial communication protocols, providing real-time machine diagnostics and seamless integration with plant automation systems. It ensures reliability and data integrity, supporting redundant configurations for critical applications.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/22M |

| Part Number | 138607-01A |

| System Compatibility | Bently Nevada 3500 Machinery Protection System |

| Primary Function | Rack Interface and Transient Data Interface |

| Rack Slot | Slot 1 (leftmost position) |

| Communication Interfaces | Ethernet (10/100 Mbps), RS-232, RS-422/485 |

| Supported Protocols | Modbus TCP/IP, System 1®, Proprietary Protocols |

| Software Integration | Compatible with System 1® Condition Monitoring Software |

| Redundancy Support | Supports dual-module redundant operation |

| LED Indicators | Status, Communication, Configuration, Network activity |

| Hot Swappable | Yes |

| Power Supply | Rack backplane powered |

| Operating Temperature | -30°C to +65°C (-22°F to +149°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Humidity | 0 to 95% RH, non-condensing |

| Shock Resistance | 10 g, 11 ms half-sine |

| Vibration Resistance | 0.5 g from 10 Hz to 500 Hz |

| Dimensions (H x W x D) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

Applications

The 3500/22M 138607-01A is used extensively in industrial sectors where machinery protection and condition monitoring are vital. Key applications include:

-

Steam and Gas Turbines

For monitoring transient vibrations and shaft position during operational changes.

-

Compressors and Pumps

To detect and analyze dynamic faults, enabling predictive maintenance.

-

Electric Motors and Generators

Providing critical data for condition-based maintenance programs.

-

Petrochemical and Refining Plants

For continuous monitoring of rotating equipment under demanding conditions.

-

Power Plants

Integration into plant-wide control systems for operational reliability.

-

Oil and Gas Extraction Facilities

Monitoring machinery in harsh environments to prevent unplanned downtime.

Product Advantages

-

Combined Functionality

Integrates rack interface and transient data capabilities, simplifying system architecture.

-

High-Speed and Reliable Communications

Offers Ethernet and serial ports supporting industry-standard protocols.

-

Advanced Transient Data Capture

Enables precise recording of machine behavior during events for effective diagnostics.

-

Redundancy Capability

Supports dual TDIs for fault-tolerant operation in critical systems.

-

System 1® Ready

Fully compatible with Bently Nevada’s System 1® software for centralized monitoring.

-

Hot-Swappable Design

Facilitates maintenance without interrupting system operation.

-

Compact, Lightweight Form Factor

Fits standard 3500 rack slots, easing installation and replacement.

Frequently Asked Questions (FAQ)

-

What is the main purpose of the 3500/22M 138607-01A module?

It functions as the communication and transient data interface for the 3500 system.

-

Which rack slot is this module installed in?

It must be installed in Slot 1.

-

Is the module compatible with System 1® software?

Yes, it seamlessly integrates with System 1®.

-

Can the module be used in a redundant configuration?

Yes, it supports dual-module redundancy.

-

What types of communication ports does it provide?

Ethernet, RS-232, and RS-422/485 serial ports.

-

Does the module support hot-swapping?

Yes, it can be replaced without shutting down the system.

-

What kind of data does it handle?

Both steady-state and transient vibration and position data.

-

What happens if the module fails during operation?

If configured redundantly, the backup module takes over without loss of data.

-

How is the module powered?

It receives power from the 3500 rack backplane.

-

Are there status indicators on the module?

Yes, LEDs indicate module health, communication status, and configuration state.

Bently Nevada 3500/22M 138607-01A Transient Data Interface Module

Manufacturer:Bently Nevada

Product Number:3500/22M 138607-01A

Product Type:Transient Data Interface Module

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:46

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/22M 138607-01A Transient Data Interface Module is an essential component of the 3500 Machinery Protection System. It acts as the primary communication hub between the rack and the external condition monitoring software, notably System 1®. This advanced module consolidates the functions of the Rack Interface Module (RIM) and transient data capture, enabling the system to collect, process, and transmit both steady-state and transient data effectively.

Designed for installation in Slot 1 of the 3500 rack, the 3500/22M 138607-01A supports high-speed Ethernet and serial communication protocols, providing real-time machine diagnostics and seamless integration with plant automation systems. It ensures reliability and data integrity, supporting redundant configurations for critical applications.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/22M |

| Part Number | 138607-01A |

| System Compatibility | Bently Nevada 3500 Machinery Protection System |

| Primary Function | Rack Interface and Transient Data Interface |

| Rack Slot | Slot 1 (leftmost position) |

| Communication Interfaces | Ethernet (10/100 Mbps), RS-232, RS-422/485 |

| Supported Protocols | Modbus TCP/IP, System 1®, Proprietary Protocols |

| Software Integration | Compatible with System 1® Condition Monitoring Software |

| Redundancy Support | Supports dual-module redundant operation |

| LED Indicators | Status, Communication, Configuration, Network activity |

| Hot Swappable | Yes |

| Power Supply | Rack backplane powered |

| Operating Temperature | -30°C to +65°C (-22°F to +149°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Humidity | 0 to 95% RH, non-condensing |

| Shock Resistance | 10 g, 11 ms half-sine |

| Vibration Resistance | 0.5 g from 10 Hz to 500 Hz |

| Dimensions (H x W x D) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

Applications

The 3500/22M 138607-01A is used extensively in industrial sectors where machinery protection and condition monitoring are vital. Key applications include:

-

Steam and Gas Turbines

For monitoring transient vibrations and shaft position during operational changes.

-

Compressors and Pumps

To detect and analyze dynamic faults, enabling predictive maintenance.

-

Electric Motors and Generators

Providing critical data for condition-based maintenance programs.

-

Petrochemical and Refining Plants

For continuous monitoring of rotating equipment under demanding conditions.

-

Power Plants

Integration into plant-wide control systems for operational reliability.

-

Oil and Gas Extraction Facilities

Monitoring machinery in harsh environments to prevent unplanned downtime.

Product Advantages

-

Combined Functionality

Integrates rack interface and transient data capabilities, simplifying system architecture.

-

High-Speed and Reliable Communications

Offers Ethernet and serial ports supporting industry-standard protocols.

-

Advanced Transient Data Capture

Enables precise recording of machine behavior during events for effective diagnostics.

-

Redundancy Capability

Supports dual TDIs for fault-tolerant operation in critical systems.

-

System 1® Ready

Fully compatible with Bently Nevada’s System 1® software for centralized monitoring.

-

Hot-Swappable Design

Facilitates maintenance without interrupting system operation.

-

Compact, Lightweight Form Factor

Fits standard 3500 rack slots, easing installation and replacement.

Frequently Asked Questions (FAQ)

-

What is the main purpose of the 3500/22M 138607-01A module?

It functions as the communication and transient data interface for the 3500 system.

-

Which rack slot is this module installed in?

It must be installed in Slot 1.

-

Is the module compatible with System 1® software?

Yes, it seamlessly integrates with System 1®.

-

Can the module be used in a redundant configuration?

Yes, it supports dual-module redundancy.

-

What types of communication ports does it provide?

Ethernet, RS-232, and RS-422/485 serial ports.

-

Does the module support hot-swapping?

Yes, it can be replaced without shutting down the system.

-

What kind of data does it handle?

Both steady-state and transient vibration and position data.

-

What happens if the module fails during operation?

If configured redundantly, the backup module takes over without loss of data.

-

How is the module powered?

It receives power from the 3500 rack backplane.

-

Are there status indicators on the module?

Yes, LEDs indicate module health, communication status, and configuration state.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...