Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

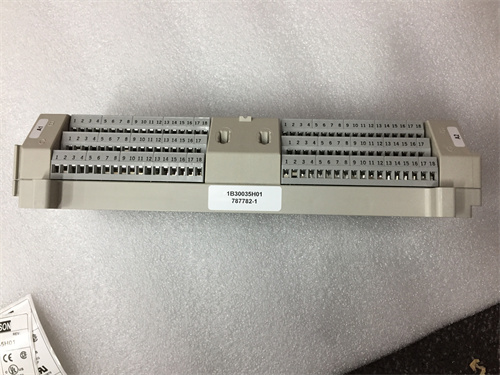

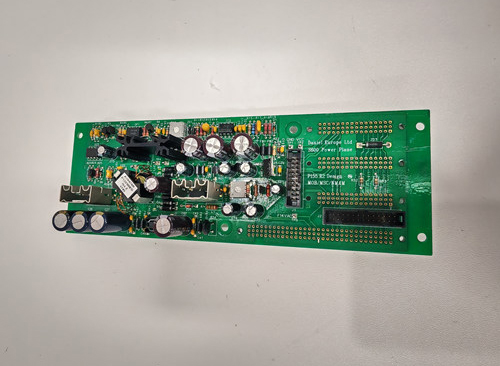

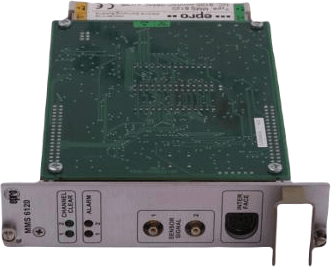

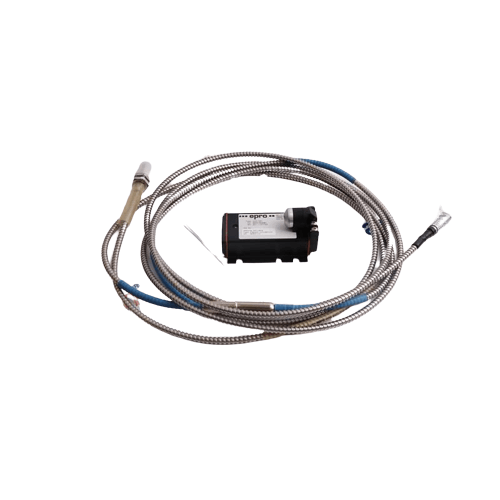

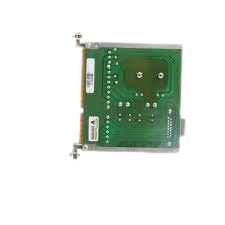

Emerson VE3007 KJ2005X1-BA1 DCS MX Controller

Manufacturer:Emerson

Product Number:VE3007 KJ2005X1-BA1

Product Type:DCS MX Controller

Origin:USA

Dimensions:160 × 90 × 80 mm

Weight :0.65 kg

Views:169

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Emerson VE3007 KJ2005X1-BA1 DCS MX Controller is a high-performance control processor designed for use in DeltaV distributed control systems. This controller is responsible for managing process automation tasks such as regulatory control, advanced process strategies, batch operations, and continuous monitoring. It provides robust integration with I/O subsystems, networks, and operator interfaces, ensuring reliable performance in critical industrial environments.

Its design emphasizes fault tolerance, high availability, and scalability, making it suitable for large-scale process industries like oil & gas, petrochemicals, power generation, and pharmaceuticals.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | VE3007 KJ2005X1-BA1 |

| Product Type | DCS MX Controller (DeltaV System) |

| Processor | High-speed 32-bit processor optimized for control tasks |

| Memory | 256 MB RAM (expandable) |

| Communication Protocols | Ethernet, DeltaV control network, Modbus TCP/IP support |

| Control Capacity | Supports up to 750 control modules |

| Redundancy | Fully supports redundant pairing for hot standby operation |

| Operating Temperature | 0°C to +50°C |

| Storage Temperature | -40°C to +70°C |

| Power Supply | 24 VDC (typical), low power consumption |

| Dimensions | 160 × 90 × 80 mm |

| Weight | 0.65 kg |

| Mounting | Standard DIN rail or chassis slot |

| Certifications | CE, CSA, UL, ATEX compliant |

Product Applications

-

Oil & Gas – Real-time process control for refining, separation, and distribution.

-

Petrochemical Plants – Advanced control for continuous and batch processes.

-

Power Generation – Turbine, boiler, and generator control.

-

Pharmaceutical Manufacturing – Batch automation and recipe-based control.

-

Pulp & Paper – Continuous process regulation and quality control.

-

Water & Wastewater – Supervisory and distributed process automation.

Product Advantages

-

High Availability: Built-in redundancy ensures uninterrupted plant operation.

-

Scalability: Can handle large systems with hundreds of modules and thousands of I/O points.

-

Flexible Integration: Supports multiple communication protocols for seamless connectivity.

-

Fast Processing: High-speed execution of complex control strategies.

-

Robust Security: Designed with secure communication and system integrity in mind.

-

Easy Maintenance: Hot-swappable capability reduces downtime and maintenance costs.

FAQ

Q1: How many I/O channels can the VE3007 controller support?

A1: The controller supports up to 750 control modules with distributed I/O across the DeltaV network.

Q2: Does the VE3007 support redundant operation?

A2: Yes, it can be paired with another controller for full redundancy and hot standby.

Q3: What communication protocols are supported by this controller?

A3: It supports Ethernet, DeltaV Control Network, and Modbus TCP/IP for integration.

Q4: Can this controller be used in safety-critical applications?

A4: Yes, it complies with industrial safety standards and can integrate with SIS (Safety Instrumented Systems).

Q5: What is the typical scan time of the VE3007 controller?

A5: The scan cycle is optimized for sub-100 ms loop execution depending on configuration.

Q6: Does the controller support batch automation?

A6: Yes, it is fully capable of batch processing control with DeltaV batch software.

Q7: How is firmware upgraded in the VE3007?

A7: Firmware can be upgraded online using DeltaV engineering tools without interrupting control.

Q8: What type of mounting does it require?

A8: It supports standard DIN rail mounting or can be installed in a DeltaV system chassis slot.

Q9: Can it integrate third-party devices?

A9: Yes, through Modbus TCP/IP and other supported protocols, it can communicate with third-party systems.

Q10: Is the controller hot-swappable?

A10: Yes, it can be replaced online in redundant configurations to minimize downtime.

Emerson VE3007 KJ2005X1-BA1 DCS MX Controller

Manufacturer:Emerson

Product Number:VE3007 KJ2005X1-BA1

Product Type:DCS MX Controller

Origin:USA

Dimensions:160 × 90 × 80 mm

Weight :0.65 kg

Views:169

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Emerson VE3007 KJ2005X1-BA1 DCS MX Controller is a high-performance control processor designed for use in DeltaV distributed control systems. This controller is responsible for managing process automation tasks such as regulatory control, advanced process strategies, batch operations, and continuous monitoring. It provides robust integration with I/O subsystems, networks, and operator interfaces, ensuring reliable performance in critical industrial environments.

Its design emphasizes fault tolerance, high availability, and scalability, making it suitable for large-scale process industries like oil & gas, petrochemicals, power generation, and pharmaceuticals.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | VE3007 KJ2005X1-BA1 |

| Product Type | DCS MX Controller (DeltaV System) |

| Processor | High-speed 32-bit processor optimized for control tasks |

| Memory | 256 MB RAM (expandable) |

| Communication Protocols | Ethernet, DeltaV control network, Modbus TCP/IP support |

| Control Capacity | Supports up to 750 control modules |

| Redundancy | Fully supports redundant pairing for hot standby operation |

| Operating Temperature | 0°C to +50°C |

| Storage Temperature | -40°C to +70°C |

| Power Supply | 24 VDC (typical), low power consumption |

| Dimensions | 160 × 90 × 80 mm |

| Weight | 0.65 kg |

| Mounting | Standard DIN rail or chassis slot |

| Certifications | CE, CSA, UL, ATEX compliant |

Product Applications

-

Oil & Gas – Real-time process control for refining, separation, and distribution.

-

Petrochemical Plants – Advanced control for continuous and batch processes.

-

Power Generation – Turbine, boiler, and generator control.

-

Pharmaceutical Manufacturing – Batch automation and recipe-based control.

-

Pulp & Paper – Continuous process regulation and quality control.

-

Water & Wastewater – Supervisory and distributed process automation.

Product Advantages

-

High Availability: Built-in redundancy ensures uninterrupted plant operation.

-

Scalability: Can handle large systems with hundreds of modules and thousands of I/O points.

-

Flexible Integration: Supports multiple communication protocols for seamless connectivity.

-

Fast Processing: High-speed execution of complex control strategies.

-

Robust Security: Designed with secure communication and system integrity in mind.

-

Easy Maintenance: Hot-swappable capability reduces downtime and maintenance costs.

FAQ

Q1: How many I/O channels can the VE3007 controller support?

A1: The controller supports up to 750 control modules with distributed I/O across the DeltaV network.

Q2: Does the VE3007 support redundant operation?

A2: Yes, it can be paired with another controller for full redundancy and hot standby.

Q3: What communication protocols are supported by this controller?

A3: It supports Ethernet, DeltaV Control Network, and Modbus TCP/IP for integration.

Q4: Can this controller be used in safety-critical applications?

A4: Yes, it complies with industrial safety standards and can integrate with SIS (Safety Instrumented Systems).

Q5: What is the typical scan time of the VE3007 controller?

A5: The scan cycle is optimized for sub-100 ms loop execution depending on configuration.

Q6: Does the controller support batch automation?

A6: Yes, it is fully capable of batch processing control with DeltaV batch software.

Q7: How is firmware upgraded in the VE3007?

A7: Firmware can be upgraded online using DeltaV engineering tools without interrupting control.

Q8: What type of mounting does it require?

A8: It supports standard DIN rail mounting or can be installed in a DeltaV system chassis slot.

Q9: Can it integrate third-party devices?

A9: Yes, through Modbus TCP/IP and other supported protocols, it can communicate with third-party systems.

Q10: Is the controller hot-swappable?

A10: Yes, it can be replaced online in redundant configurations to minimize downtime.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...