Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

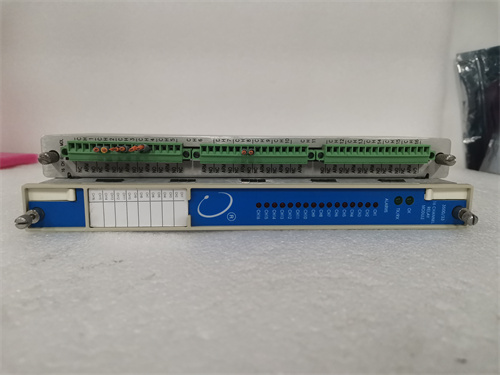

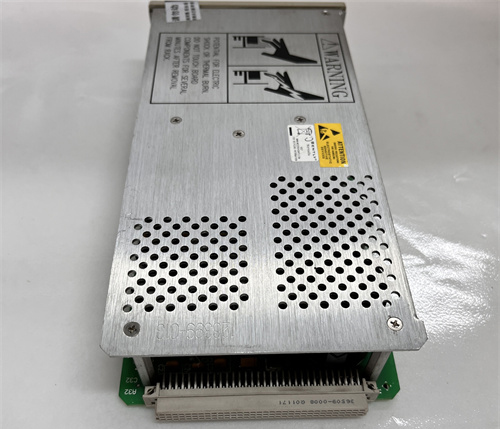

Bently Nevada 177230-01-02-05 Seismic Transmitter

Manufacturer:Bently Nevada

Product Number:177230-01-02-05

Product Type:Seismic Transmitter

Origin:USA

Sensor Head Diameter:25.4 mm

Weight:0.131 kg

Views:79

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 177230-01-02-05 is a high-performance vibration monitoring system designed for critical machinery in industrial settings. It is part of the Bently Nevada product family, renowned for delivering advanced predictive maintenance solutions and ensuring the smooth operation of rotating equipment. This product is specifically engineered to monitor machinery conditions, providing real-time insights that help prevent unexpected downtime and costly repairs.

This monitoring system integrates with Bently Nevada’s sophisticated machinery protection and condition monitoring products to help industries manage their assets effectively. Its capabilities include continuous vibration monitoring, data collection, and the ability to provide alerts based on predefined thresholds, all of which enable operators to perform predictive maintenance.

Product Specifications

| Specification | Details |

|---|---|

| Model | Bently Nevada 177230-01-02-05 |

| Type | Seismic Transmitter |

| Input Voltage | 24 VDC |

| Frequency Range | 10 Hz to 10 kHz |

| Accuracy | ±0.5% of full scale |

| Temperature Range | -20°C to +60°C |

| Sensor Head Diameter | 25.4 mm |

| Weight | 0.131 kg |

| Mounting Type | Panel or DIN rail mounting |

| Communication Interface | Modbus RTU, Ethernet (optional) |

| Input Channels | 4 Analog input channels |

| Output Channels | 2 Relay outputs |

| Power Consumption | 6W (maximum) |

Applications

The Bently Nevada 177230-01-02-05 is used in a variety of industrial applications, including but not limited to:

- Power Generation Plants: To monitor critical components such as turbines, compressors, and generators.

- Oil and Gas: Monitoring of pumping stations, compressors, and other critical equipment.

- Chemical and Petrochemical Plants: Ensuring the reliability of high-speed machinery such as pumps, motors, and compressors.

- Mining: Monitoring crushers, mills, and other machinery involved in the extraction process.

- Paper and Pulp Industry: Vibration monitoring of large machinery like paper mills, pumps, and conveyor belts.

Advantages

- Predictive Maintenance: The system provides real-time vibration data, enabling users to predict when a machine may fail, allowing for scheduled maintenance and minimizing downtime.

- Early Fault Detection: By identifying issues at early stages, it helps in taking corrective actions before they escalate into major problems, reducing costly repairs.

- Customization: The system allows for flexible threshold settings to tailor the monitoring system according to the specific machinery needs.

- Ease of Integration: Can easily integrate with existing machinery protection systems and automation networks.

- Data Logging: Offers robust data logging features, allowing operators to track vibration trends over time.

- Alarm and Notification Features: Equipped with alarms and notifications that alert operators when thresholds are exceeded, ensuring timely intervention.

- Enhanced Reliability: The Bently Nevada 177230-01-02-05 ensures continuous operation of critical equipment, increasing overall plant reliability.

- Advanced Diagnostics: Provides advanced diagnostics that help in detailed root-cause analysis of any performance issues.

Bently Nevada 177230-01-02-05 Seismic Transmitter

Manufacturer:Bently Nevada

Product Number:177230-01-02-05

Product Type:Seismic Transmitter

Origin:USA

Sensor Head Diameter:25.4 mm

Weight:0.131 kg

Views:79

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 177230-01-02-05 is a high-performance vibration monitoring system designed for critical machinery in industrial settings. It is part of the Bently Nevada product family, renowned for delivering advanced predictive maintenance solutions and ensuring the smooth operation of rotating equipment. This product is specifically engineered to monitor machinery conditions, providing real-time insights that help prevent unexpected downtime and costly repairs.

This monitoring system integrates with Bently Nevada’s sophisticated machinery protection and condition monitoring products to help industries manage their assets effectively. Its capabilities include continuous vibration monitoring, data collection, and the ability to provide alerts based on predefined thresholds, all of which enable operators to perform predictive maintenance.

Product Specifications

| Specification | Details |

|---|---|

| Model | Bently Nevada 177230-01-02-05 |

| Type | Seismic Transmitter |

| Input Voltage | 24 VDC |

| Frequency Range | 10 Hz to 10 kHz |

| Accuracy | ±0.5% of full scale |

| Temperature Range | -20°C to +60°C |

| Sensor Head Diameter | 25.4 mm |

| Weight | 0.131 kg |

| Mounting Type | Panel or DIN rail mounting |

| Communication Interface | Modbus RTU, Ethernet (optional) |

| Input Channels | 4 Analog input channels |

| Output Channels | 2 Relay outputs |

| Power Consumption | 6W (maximum) |

Applications

The Bently Nevada 177230-01-02-05 is used in a variety of industrial applications, including but not limited to:

- Power Generation Plants: To monitor critical components such as turbines, compressors, and generators.

- Oil and Gas: Monitoring of pumping stations, compressors, and other critical equipment.

- Chemical and Petrochemical Plants: Ensuring the reliability of high-speed machinery such as pumps, motors, and compressors.

- Mining: Monitoring crushers, mills, and other machinery involved in the extraction process.

- Paper and Pulp Industry: Vibration monitoring of large machinery like paper mills, pumps, and conveyor belts.

Advantages

- Predictive Maintenance: The system provides real-time vibration data, enabling users to predict when a machine may fail, allowing for scheduled maintenance and minimizing downtime.

- Early Fault Detection: By identifying issues at early stages, it helps in taking corrective actions before they escalate into major problems, reducing costly repairs.

- Customization: The system allows for flexible threshold settings to tailor the monitoring system according to the specific machinery needs.

- Ease of Integration: Can easily integrate with existing machinery protection systems and automation networks.

- Data Logging: Offers robust data logging features, allowing operators to track vibration trends over time.

- Alarm and Notification Features: Equipped with alarms and notifications that alert operators when thresholds are exceeded, ensuring timely intervention.

- Enhanced Reliability: The Bently Nevada 177230-01-02-05 ensures continuous operation of critical equipment, increasing overall plant reliability.

- Advanced Diagnostics: Provides advanced diagnostics that help in detailed root-cause analysis of any performance issues.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...