Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

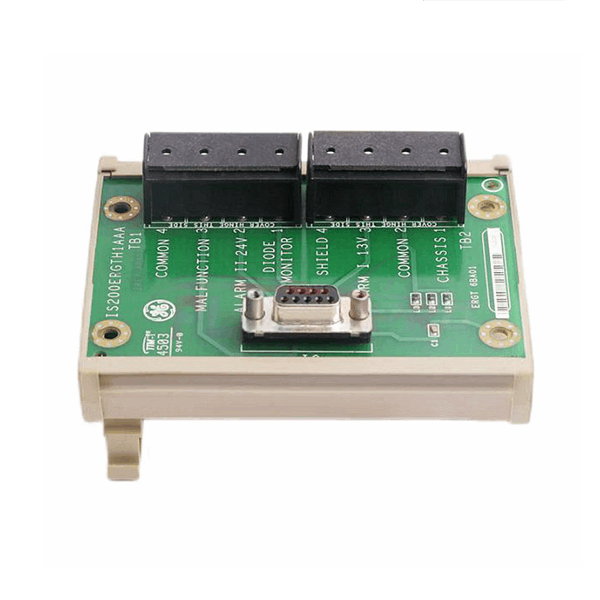

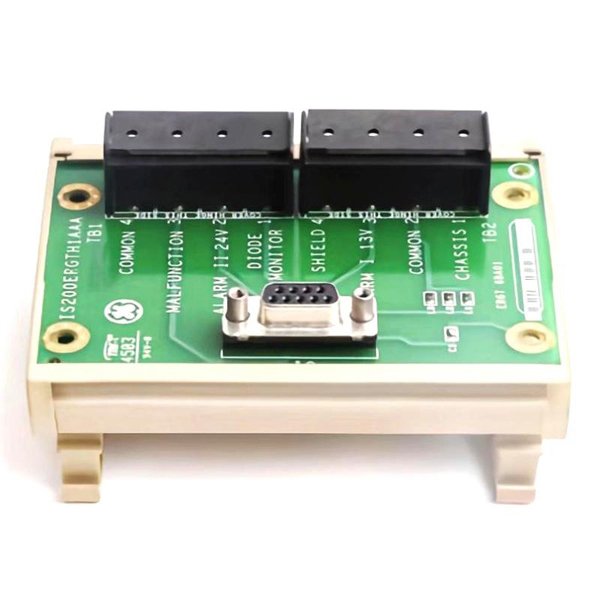

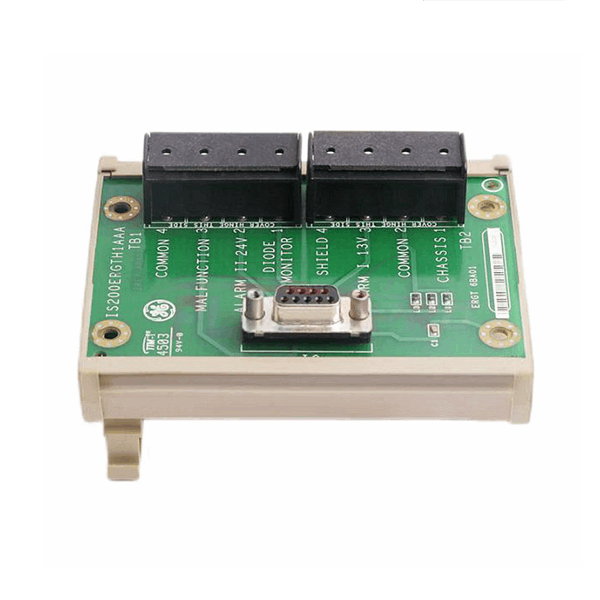

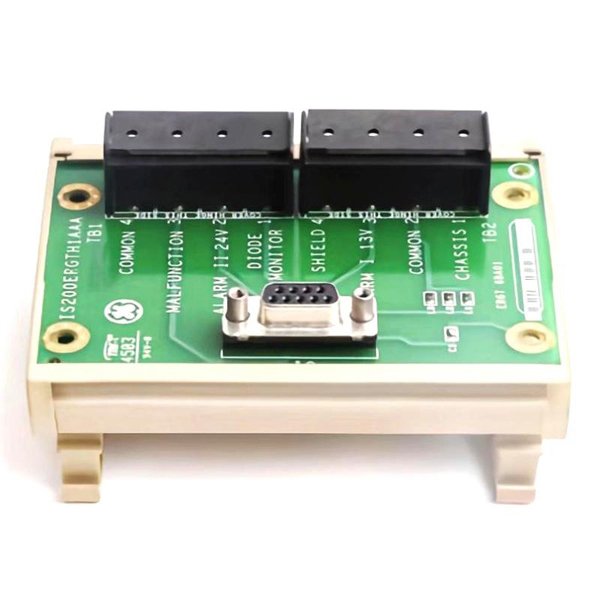

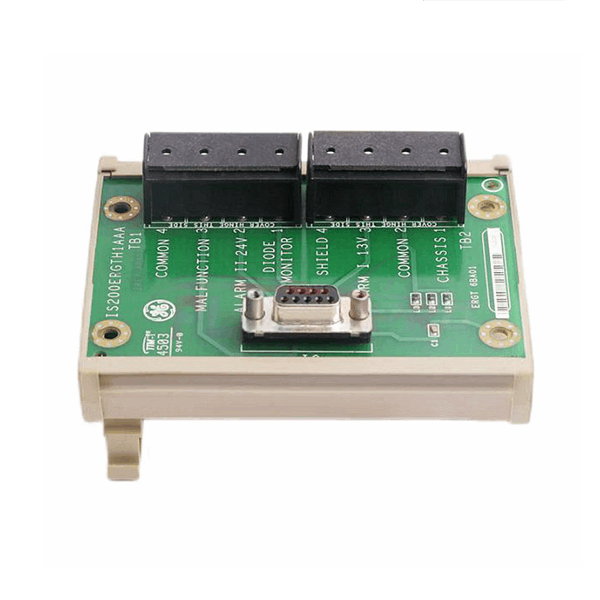

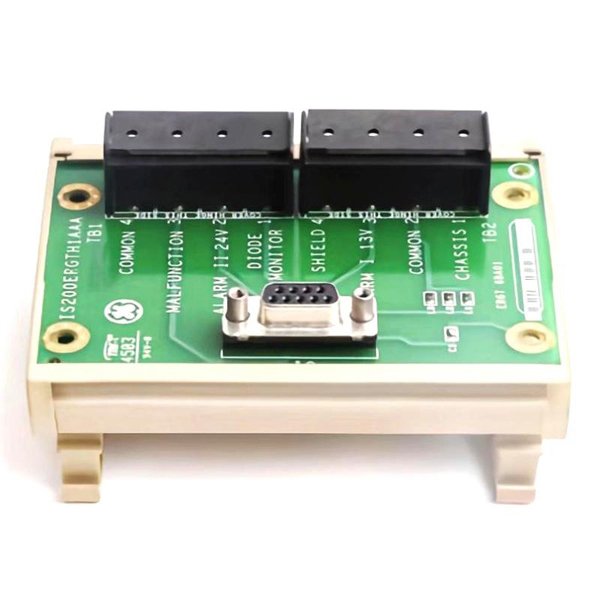

General Electric IS200ERGTH1A Ground detector terminal board

Manufacturer:GE

Product Number:IS200ERGTH1A

:

Origin:USA

Dimensions:GE

Views:29

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200ERGTH1A is a high-performance component designed for use in advanced industrial systems, particularly in control systems for power generation and process industries. Manufactured by General Electric, this product is a part of the Mark VIe series of control systems, offering state-of-the-art technology for reliable, efficient, and secure operations. It is known for its durability and its ability to handle complex control tasks with precision. The IS200ERGTH1A plays a pivotal role in maintaining operational safety and optimizing performance across various applications.

Technical Specifications

The following table outlines the key technical specifications of the GE IS200ERGTH1A:

| Specification | Details |

|---|---|

| Model | IS200ERGTH1A |

| Dimensions (LxWxH) | 120 x 80 x 40 mm |

| Weight | 0.8kg |

| Voltage | 24 V DC |

| Operating Temperature | -40°C to 85°C |

| Mounting Type | Rack-mounted |

| Input | 24 V DC |

| Output | 24 V DC |

| Bus Interface | Ethernet, Serial |

| Communication Protocols | TCP/IP, Modbus, Profibus |

| Status Indicators | LED Indicators |

Applications

The GE IS200ERGTH1A is widely used in applications that require high-performance control and monitoring systems. Key areas of application include:

-

Power Generation: Used in turbine and generator control systems to monitor and regulate performance.

-

Industrial Automation: Implements automation systems in manufacturing, processing, and assembly plants.

-

Oil & Gas: Plays a critical role in refining, extraction, and transportation processes by providing reliable control systems.

-

Water Treatment: Ensures smooth operations in water plants by controlling pumps, valves, and other critical infrastructure.

-

Transportation: Integral in controlling operations of electric grids, railway systems, and other vital infrastructure.

Product Advantages

The GE IS200ERGTH1A offers several advantages that make it a preferred choice in industrial control applications:

-

Reliability: Built to operate in harsh industrial environments with excellent temperature tolerance and resilience to wear.

-

Scalability: Suitable for both small and large scale systems, offering flexibility in integration and expansion.

-

Compatibility: Fully compatible with existing GE control systems and various communication protocols for easy integration.

-

High Performance: Provides real-time data processing and control, optimizing the performance of connected machinery.

-

Durability: Designed for long-term use with robust components that withstand environmental stress, making it a cost-effective solution for companies.

-

Ease of Maintenance: Modular design allows for easier maintenance and replacement, minimizing system downtime.

FAQ

Q1: What is the primary function of the GE IS200ERGTH1A?

A1: The GE IS200ERGTH1A is a control system module designed for use in industrial automation, power generation, and process control applications. It monitors and regulates system parameters to optimize performance.

Q2: Can the IS200ERGTH1A be used in extreme environmental conditions?

A2: Yes, the IS200ERGTH1A is designed to withstand harsh industrial environments, with an operational temperature range of -40°C to 85°C.

Q3: What communication protocols are supported by the IS200ERGTH1A?

A3: It supports TCP/IP, Modbus, and Profibus communication protocols, enabling seamless integration with existing systems.

Q4: How is the IS200ERGTH1A mounted?

A4: The IS200ERGTH1A is designed for rack-mount installation, which makes it suitable for various industrial setups.

Q5: What is the input voltage required for the GE IS200ERGTH1A?

A5: The IS200ERGTH1A operates with a 24 V DC input voltage.

Q6: Is the IS200ERGTH1A compatible with GE’s Mark VIe control systems?

A6: Yes, the IS200ERGTH1A is a part of the GE Mark VIe series and integrates seamlessly with other components in this system.

Q7: How much does the GE IS200ERGTH1A weigh?

A7: The weight of the GE IS200ERGTH1A is 0.8 kg.

Q8: What is the typical use case for the IS200ERGTH1A in the power generation industry?

A8: In power generation, it is used for controlling turbines and generators, ensuring efficient and safe operation by monitoring real-time performance data.

Q9: What are the key features of the IS200ERGTH1A’s status indicators?

A9: The IS200ERGTH1A features LED indicators that provide visual status updates on the system’s operational health, aiding in quick diagnostics.

Q10: Can the GE IS200ERGTH1A be used in water treatment plants?

A10: Yes, the IS200ERGTH1A is well-suited for use in water treatment plants, helping to control pumps, valves, and other critical systems.

General Electric IS200ERGTH1A Ground detector terminal board

Manufacturer:GE

Product Number:IS200ERGTH1A

:

Origin:USA

Dimensions:GE

Views:29

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200ERGTH1A is a high-performance component designed for use in advanced industrial systems, particularly in control systems for power generation and process industries. Manufactured by General Electric, this product is a part of the Mark VIe series of control systems, offering state-of-the-art technology for reliable, efficient, and secure operations. It is known for its durability and its ability to handle complex control tasks with precision. The IS200ERGTH1A plays a pivotal role in maintaining operational safety and optimizing performance across various applications.

Technical Specifications

The following table outlines the key technical specifications of the GE IS200ERGTH1A:

| Specification | Details |

|---|---|

| Model | IS200ERGTH1A |

| Dimensions (LxWxH) | 120 x 80 x 40 mm |

| Weight | 0.8kg |

| Voltage | 24 V DC |

| Operating Temperature | -40°C to 85°C |

| Mounting Type | Rack-mounted |

| Input | 24 V DC |

| Output | 24 V DC |

| Bus Interface | Ethernet, Serial |

| Communication Protocols | TCP/IP, Modbus, Profibus |

| Status Indicators | LED Indicators |

Applications

The GE IS200ERGTH1A is widely used in applications that require high-performance control and monitoring systems. Key areas of application include:

-

Power Generation: Used in turbine and generator control systems to monitor and regulate performance.

-

Industrial Automation: Implements automation systems in manufacturing, processing, and assembly plants.

-

Oil & Gas: Plays a critical role in refining, extraction, and transportation processes by providing reliable control systems.

-

Water Treatment: Ensures smooth operations in water plants by controlling pumps, valves, and other critical infrastructure.

-

Transportation: Integral in controlling operations of electric grids, railway systems, and other vital infrastructure.

Product Advantages

The GE IS200ERGTH1A offers several advantages that make it a preferred choice in industrial control applications:

-

Reliability: Built to operate in harsh industrial environments with excellent temperature tolerance and resilience to wear.

-

Scalability: Suitable for both small and large scale systems, offering flexibility in integration and expansion.

-

Compatibility: Fully compatible with existing GE control systems and various communication protocols for easy integration.

-

High Performance: Provides real-time data processing and control, optimizing the performance of connected machinery.

-

Durability: Designed for long-term use with robust components that withstand environmental stress, making it a cost-effective solution for companies.

-

Ease of Maintenance: Modular design allows for easier maintenance and replacement, minimizing system downtime.

FAQ

Q1: What is the primary function of the GE IS200ERGTH1A?

A1: The GE IS200ERGTH1A is a control system module designed for use in industrial automation, power generation, and process control applications. It monitors and regulates system parameters to optimize performance.

Q2: Can the IS200ERGTH1A be used in extreme environmental conditions?

A2: Yes, the IS200ERGTH1A is designed to withstand harsh industrial environments, with an operational temperature range of -40°C to 85°C.

Q3: What communication protocols are supported by the IS200ERGTH1A?

A3: It supports TCP/IP, Modbus, and Profibus communication protocols, enabling seamless integration with existing systems.

Q4: How is the IS200ERGTH1A mounted?

A4: The IS200ERGTH1A is designed for rack-mount installation, which makes it suitable for various industrial setups.

Q5: What is the input voltage required for the GE IS200ERGTH1A?

A5: The IS200ERGTH1A operates with a 24 V DC input voltage.

Q6: Is the IS200ERGTH1A compatible with GE’s Mark VIe control systems?

A6: Yes, the IS200ERGTH1A is a part of the GE Mark VIe series and integrates seamlessly with other components in this system.

Q7: How much does the GE IS200ERGTH1A weigh?

A7: The weight of the GE IS200ERGTH1A is 0.8 kg.

Q8: What is the typical use case for the IS200ERGTH1A in the power generation industry?

A8: In power generation, it is used for controlling turbines and generators, ensuring efficient and safe operation by monitoring real-time performance data.

Q9: What are the key features of the IS200ERGTH1A’s status indicators?

A9: The IS200ERGTH1A features LED indicators that provide visual status updates on the system’s operational health, aiding in quick diagnostics.

Q10: Can the GE IS200ERGTH1A be used in water treatment plants?

A10: Yes, the IS200ERGTH1A is well-suited for use in water treatment plants, helping to control pumps, valves, and other critical systems.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...