Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

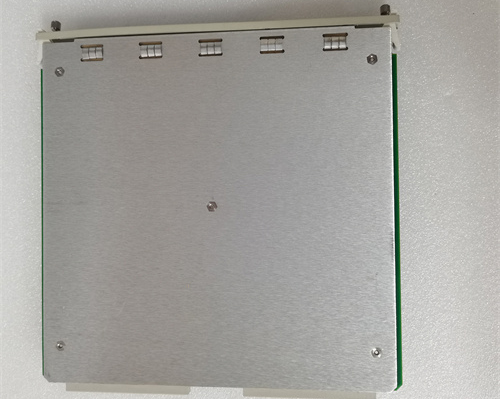

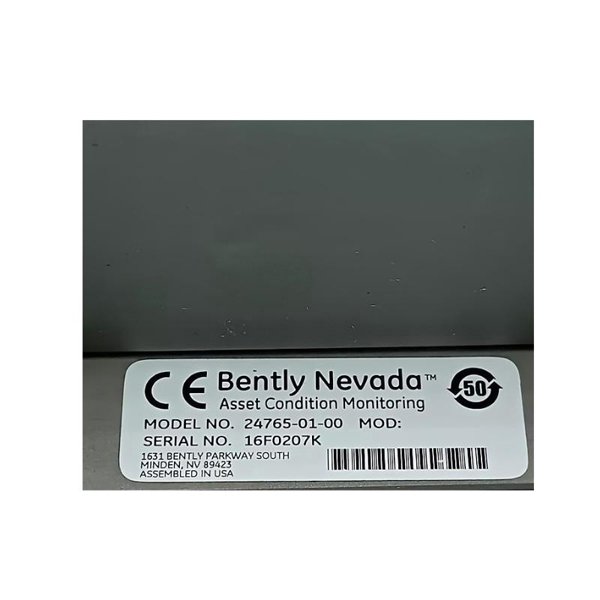

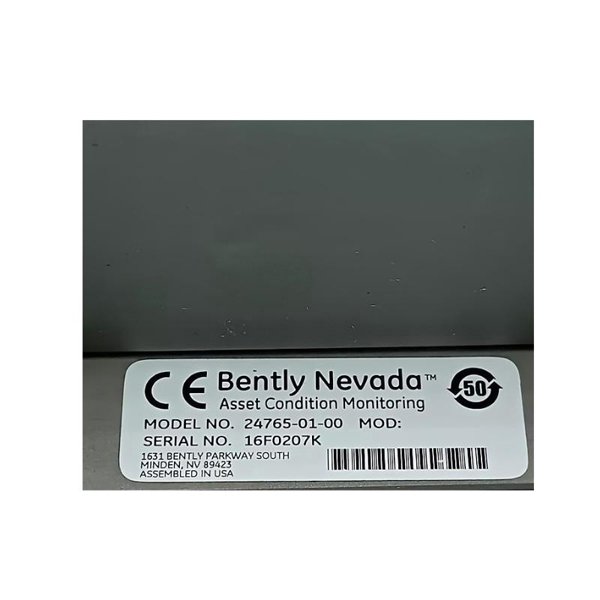

Bently Nevada 24765-01-00 Case Expansion Transducer Assembly

Manufacturer:Bently Nevada

Product Number:24765-01-00

Product Type:Case Expansion Transducer Assembly

Origin:USA

Dimensions:88.9 x 117 x 241 mm

Weight:2.3 kg

Views:70

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 24765-01-00 Case Expansion Transducer Assembly is a high-precision measurement device designed for monitoring machinery vibration and expansion in critical industrial applications. It is engineered to convert mechanical expansion of machine casings into electrical signals that can be read by monitoring systems, providing real-time data for equipment health and performance analysis. This transducer assembly is widely used in turbomachinery, compressors, pumps, and rotating equipment where accurate vibration and expansion monitoring is essential.

Constructed with robust materials and precision-engineered components, the 24765-01-00 ensures stable signal output, high reliability, and excellent repeatability under demanding conditions. Its design allows for integration into existing Bently Nevada monitoring systems, supporting predictive maintenance strategies and reducing the risk of unexpected machinery failure.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 24765-01-00 |

| Type | Case Expansion Transducer Assembly |

| Measurement Principle | Linear displacement via case expansion |

| Output Signal | 4–20 mA or voltage signal (depending on system) |

| Sensitivity | High sensitivity for low-amplitude expansion |

| Mounting Type | Flange or stud mounting |

| Operating Temperature | -40°C to +120°C |

| Input Voltage | 24 VDC nominal |

| Environmental Protection | IP65/IP66 (depending on installation) |

| Response Frequency | Up to 5 kHz |

| Dimensions (L x W x H) | 88.9 x 117 x 241 mm |

| Weight | 2.3 kg |

| Materials | Stainless steel housing, precision sensor elements |

| Certifications | CE, RoHS, UL |

Product Applications

-

Rotating machinery monitoring: turbines, compressors, and pumps.

-

Real-time case expansion and vibration measurement for predictive maintenance.

-

Integration into Bently Nevada 3500 or 3700 monitoring systems.

-

Industrial machinery where precise expansion detection can prevent mechanical failure.

-

Oil and gas, power generation, and petrochemical industries.

-

Condition monitoring for machinery health and performance optimization.

Product Advantages

-

High-precision measurement ensures accurate monitoring of machine expansion.

-

Robust design tolerates harsh industrial environments.

-

Compatible with Bently Nevada monitoring systems for seamless integration.

-

High sensitivity allows detection of minor expansion or vibration changes.

-

IP-rated housing provides protection against dust and moisture.

-

Supports predictive maintenance, reducing unplanned downtime and operational costs.

FAQ

-

What is the primary function of the 24765-01-00 transducer?

It converts mechanical case expansion into an electrical signal for monitoring systems.

-

Which types of equipment can it be installed on?

Turbomachinery, pumps, compressors, and other rotating equipment.

-

What type of output signal does the transducer provide?

It provides a 4–20 mA current signal or voltage signal compatible with Bently Nevada systems.

-

How sensitive is the transducer?

It is designed for high sensitivity, capable of detecting small expansions and low-amplitude vibrations.

-

Does it require calibration before installation?

Yes, factory calibration ensures accurate signal output, but field verification may be performed after installation.

-

What is the operating temperature range?

The device can operate between -40°C and +120°C.

-

Can it withstand industrial environmental conditions?

Yes, the IP65/IP66 rated housing protects against dust, moisture, and other harsh conditions.

-

How is it mounted?

Using a flange or stud mounting, depending on the machine interface.

-

Is it compatible with all Bently Nevada monitoring systems?

It is compatible with most Bently Nevada monitoring platforms, including 3500 and 3700 series.

-

What is the maximum response frequency?

The transducer can respond to frequencies up to 5 kHz, allowing real-time measurement of rapid expansion events.

Bently Nevada 24765-01-00 Case Expansion Transducer Assembly

Manufacturer:Bently Nevada

Product Number:24765-01-00

Product Type:Case Expansion Transducer Assembly

Origin:USA

Dimensions:88.9 x 117 x 241 mm

Weight:2.3 kg

Views:70

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 24765-01-00 Case Expansion Transducer Assembly is a high-precision measurement device designed for monitoring machinery vibration and expansion in critical industrial applications. It is engineered to convert mechanical expansion of machine casings into electrical signals that can be read by monitoring systems, providing real-time data for equipment health and performance analysis. This transducer assembly is widely used in turbomachinery, compressors, pumps, and rotating equipment where accurate vibration and expansion monitoring is essential.

Constructed with robust materials and precision-engineered components, the 24765-01-00 ensures stable signal output, high reliability, and excellent repeatability under demanding conditions. Its design allows for integration into existing Bently Nevada monitoring systems, supporting predictive maintenance strategies and reducing the risk of unexpected machinery failure.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 24765-01-00 |

| Type | Case Expansion Transducer Assembly |

| Measurement Principle | Linear displacement via case expansion |

| Output Signal | 4–20 mA or voltage signal (depending on system) |

| Sensitivity | High sensitivity for low-amplitude expansion |

| Mounting Type | Flange or stud mounting |

| Operating Temperature | -40°C to +120°C |

| Input Voltage | 24 VDC nominal |

| Environmental Protection | IP65/IP66 (depending on installation) |

| Response Frequency | Up to 5 kHz |

| Dimensions (L x W x H) | 88.9 x 117 x 241 mm |

| Weight | 2.3 kg |

| Materials | Stainless steel housing, precision sensor elements |

| Certifications | CE, RoHS, UL |

Product Applications

-

Rotating machinery monitoring: turbines, compressors, and pumps.

-

Real-time case expansion and vibration measurement for predictive maintenance.

-

Integration into Bently Nevada 3500 or 3700 monitoring systems.

-

Industrial machinery where precise expansion detection can prevent mechanical failure.

-

Oil and gas, power generation, and petrochemical industries.

-

Condition monitoring for machinery health and performance optimization.

Product Advantages

-

High-precision measurement ensures accurate monitoring of machine expansion.

-

Robust design tolerates harsh industrial environments.

-

Compatible with Bently Nevada monitoring systems for seamless integration.

-

High sensitivity allows detection of minor expansion or vibration changes.

-

IP-rated housing provides protection against dust and moisture.

-

Supports predictive maintenance, reducing unplanned downtime and operational costs.

FAQ

-

What is the primary function of the 24765-01-00 transducer?

It converts mechanical case expansion into an electrical signal for monitoring systems.

-

Which types of equipment can it be installed on?

Turbomachinery, pumps, compressors, and other rotating equipment.

-

What type of output signal does the transducer provide?

It provides a 4–20 mA current signal or voltage signal compatible with Bently Nevada systems.

-

How sensitive is the transducer?

It is designed for high sensitivity, capable of detecting small expansions and low-amplitude vibrations.

-

Does it require calibration before installation?

Yes, factory calibration ensures accurate signal output, but field verification may be performed after installation.

-

What is the operating temperature range?

The device can operate between -40°C and +120°C.

-

Can it withstand industrial environmental conditions?

Yes, the IP65/IP66 rated housing protects against dust, moisture, and other harsh conditions.

-

How is it mounted?

Using a flange or stud mounting, depending on the machine interface.

-

Is it compatible with all Bently Nevada monitoring systems?

It is compatible with most Bently Nevada monitoring platforms, including 3500 and 3700 series.

-

What is the maximum response frequency?

The transducer can respond to frequencies up to 5 kHz, allowing real-time measurement of rapid expansion events.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...