Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

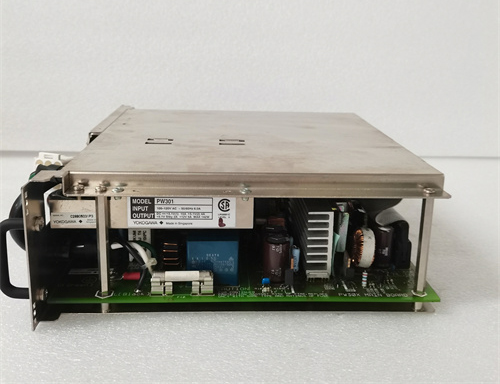

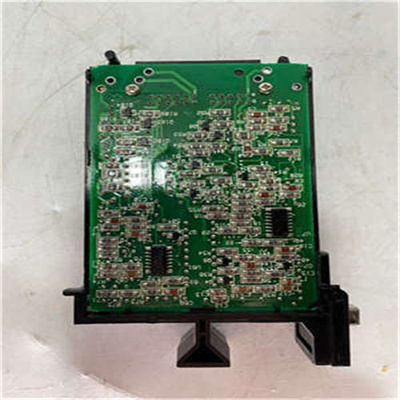

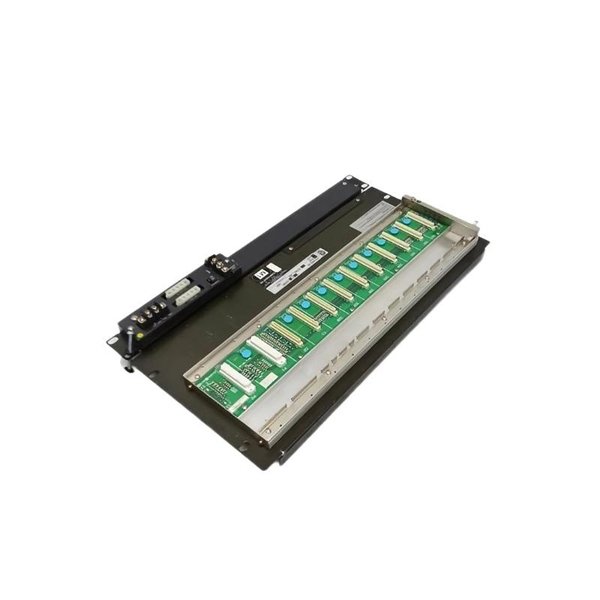

Yokogawa AFV10D-S41101 Duplexed Field Control Unit

Manufacturer:Yokogawa

Product Number:AFV10D-S41101

Product Type:Duplexed Field Control Unit

Origin:Japan

Dimensions:207 × 265.9 x 482.6 mm

Weight:8 kg

Views:69

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

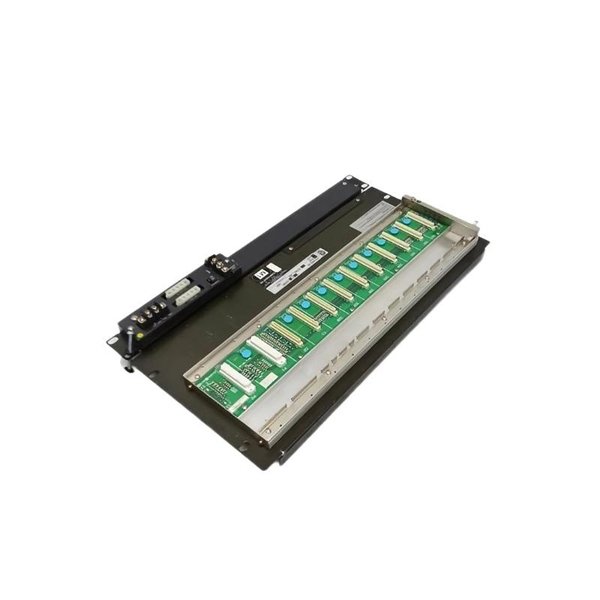

The Yokogawa AFV10D-S41101 Duplexed Field Control Unit is a robust, high-reliability control device designed to meet the rigorous demands of modern industrial automation systems. Featuring a duplexed architecture, this unit contains two independent control channels operating in parallel, providing continuous, fault-tolerant operation critical for process safety and reliability.

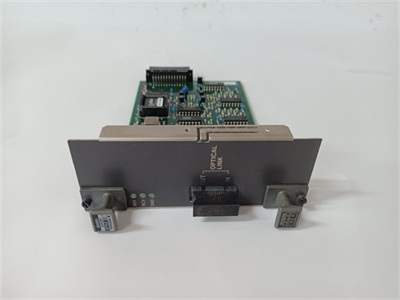

Designed as part of Yokogawa’s advanced control solutions, the AFV10D-S41101 offers seamless integration with the ProSafe-RS safety instrumented system and the CENTUM VP distributed control system, supporting complex and safety-critical process automation. The unit efficiently manages input/output from field devices, processes operational data, and communicates with higher-level control and monitoring systems via industry-standard protocols.

Its rugged construction ensures long-term stability and performance even in harsh industrial environments, making it an ideal choice for sectors where uptime and safety are paramount, such as oil & gas, petrochemical, power generation, and nuclear facilities.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | AFV10D-S41101 |

| Control Architecture | Duplexed (Dual independent processors) |

| Processor Type | Industrial-grade high-performance CPUs |

| Communication Interfaces | Ethernet (TCP/IP), Modbus, Fieldbus, Serial ports |

| Supported I/O Modules | Digital and analog inputs/outputs |

| Power Supply | Dual redundant 24 V DC inputs |

| Operating Temperature Range | 0°C to 55°C |

| Storage Temperature Range | -20°C to 70°C |

| Relative Humidity | 10% to 90%, non-condensing |

| Dimensions (W × H × D) | 207 × 265.9 x 482.6 mm |

| Weight | 8 kg |

| Mounting | Panel or rack mountable |

| Safety Certifications | IEC 61508 SIL3, CE, UL |

| Redundancy | Full duplex control with automatic channel switchover |

Applications

The AFV10D-S41101 Duplexed Field Control Unit serves as a critical component in a wide range of industrial automation and safety systems, including:

-

Safety Instrumented Systems (SIS): Ensures continuous operation of emergency shutdown and safety monitoring in oil & gas, chemical, and refining plants.

-

Power Generation: Controls turbine operations, boiler management, and other vital processes requiring fault-tolerant control.

-

Nuclear Power Facilities: Meets strict regulatory requirements with reliable fail-safe architecture.

-

Petrochemical and Chemical Processing: Supports complex process control and safety interlocking.

-

Water Treatment and Distribution: Controls and monitors treatment processes ensuring uninterrupted service.

-

Offshore and Marine: Designed to withstand harsh environmental conditions typical of offshore platforms.

-

Manufacturing: Provides high availability control for production lines requiring zero downtime.

-

Critical Infrastructure: Applied in facilities where safety and continuous operation are essential, such as airports and transportation hubs.

Advantages

-

True duplex architecture: Two completely independent control channels ensure no single point of failure.

-

High reliability and availability: Automatic fault detection and seamless failover prevent process interruptions.

-

Compliance with IEC 61508 SIL3: Certified for the highest safety integrity levels required in critical applications.

-

Robust environmental tolerance: Operates reliably across a broad temperature and humidity range.

-

Flexible communications: Supports multiple industrial communication protocols for easy integration.

-

Compact design: Space-saving panel or rack mount allows efficient use of control room real estate.

-

Redundant power supply inputs: Enhances system security by protecting against power interruptions.

-

Advanced diagnostics: Built-in monitoring tools enable early fault detection and predictive maintenance.

-

Seamless integration with Yokogawa systems: Compatible with ProSafe-RS and CENTUM VP for unified control and safety management.

-

Proven performance record: Backed by Yokogawa’s decades of experience in automation technology.

Frequently Asked Questions (FAQ)

-

What is the key benefit of the duplexed design in the AFV10D-S41101?

It ensures continuous operation by having two independent control processors that back each other up.

-

Is the AFV10D-S41101 compatible with Yokogawa’s ProSafe-RS system?

Yes, it is specifically designed to work within the ProSafe-RS safety instrumented system.

-

What safety standards does this unit comply with?

It meets IEC 61508 SIL3, CE, and UL certifications.

-

Can this unit manage both analog and digital inputs/outputs?

Yes, it supports a broad range of both digital and analog I/O modules.

-

What are the mounting options for this control unit?

It supports panel or rack mounting depending on installation needs.

-

What is the temperature operating range of the AFV10D-S41101?

The unit reliably operates between 0°C and 55°C.

-

Does the unit feature redundant power supplies?

Yes, it includes dual 24 V DC redundant power inputs.

-

How does the system handle failure of one control channel?

Control automatically switches to the other channel without any loss of control.

-

Can this unit be monitored or controlled remotely?

Yes, Ethernet communication interfaces support remote diagnostics and control.

-

What routine maintenance is required?

Regular system health checks and software/firmware updates are recommended for optimal operation.

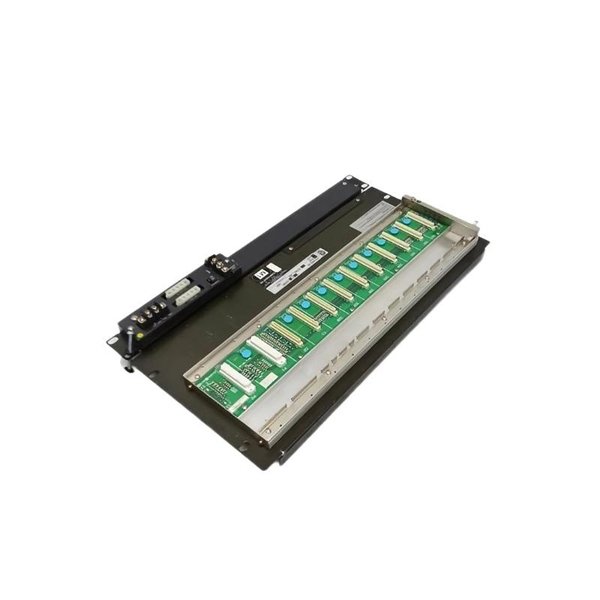

Yokogawa AFV10D-S41101 Duplexed Field Control Unit

Manufacturer:Yokogawa

Product Number:AFV10D-S41101

Product Type:Duplexed Field Control Unit

Origin:Japan

Dimensions:207 × 265.9 x 482.6 mm

Weight:8 kg

Views:69

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa AFV10D-S41101 Duplexed Field Control Unit is a robust, high-reliability control device designed to meet the rigorous demands of modern industrial automation systems. Featuring a duplexed architecture, this unit contains two independent control channels operating in parallel, providing continuous, fault-tolerant operation critical for process safety and reliability.

Designed as part of Yokogawa’s advanced control solutions, the AFV10D-S41101 offers seamless integration with the ProSafe-RS safety instrumented system and the CENTUM VP distributed control system, supporting complex and safety-critical process automation. The unit efficiently manages input/output from field devices, processes operational data, and communicates with higher-level control and monitoring systems via industry-standard protocols.

Its rugged construction ensures long-term stability and performance even in harsh industrial environments, making it an ideal choice for sectors where uptime and safety are paramount, such as oil & gas, petrochemical, power generation, and nuclear facilities.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | AFV10D-S41101 |

| Control Architecture | Duplexed (Dual independent processors) |

| Processor Type | Industrial-grade high-performance CPUs |

| Communication Interfaces | Ethernet (TCP/IP), Modbus, Fieldbus, Serial ports |

| Supported I/O Modules | Digital and analog inputs/outputs |

| Power Supply | Dual redundant 24 V DC inputs |

| Operating Temperature Range | 0°C to 55°C |

| Storage Temperature Range | -20°C to 70°C |

| Relative Humidity | 10% to 90%, non-condensing |

| Dimensions (W × H × D) | 207 × 265.9 x 482.6 mm |

| Weight | 8 kg |

| Mounting | Panel or rack mountable |

| Safety Certifications | IEC 61508 SIL3, CE, UL |

| Redundancy | Full duplex control with automatic channel switchover |

Applications

The AFV10D-S41101 Duplexed Field Control Unit serves as a critical component in a wide range of industrial automation and safety systems, including:

-

Safety Instrumented Systems (SIS): Ensures continuous operation of emergency shutdown and safety monitoring in oil & gas, chemical, and refining plants.

-

Power Generation: Controls turbine operations, boiler management, and other vital processes requiring fault-tolerant control.

-

Nuclear Power Facilities: Meets strict regulatory requirements with reliable fail-safe architecture.

-

Petrochemical and Chemical Processing: Supports complex process control and safety interlocking.

-

Water Treatment and Distribution: Controls and monitors treatment processes ensuring uninterrupted service.

-

Offshore and Marine: Designed to withstand harsh environmental conditions typical of offshore platforms.

-

Manufacturing: Provides high availability control for production lines requiring zero downtime.

-

Critical Infrastructure: Applied in facilities where safety and continuous operation are essential, such as airports and transportation hubs.

Advantages

-

True duplex architecture: Two completely independent control channels ensure no single point of failure.

-

High reliability and availability: Automatic fault detection and seamless failover prevent process interruptions.

-

Compliance with IEC 61508 SIL3: Certified for the highest safety integrity levels required in critical applications.

-

Robust environmental tolerance: Operates reliably across a broad temperature and humidity range.

-

Flexible communications: Supports multiple industrial communication protocols for easy integration.

-

Compact design: Space-saving panel or rack mount allows efficient use of control room real estate.

-

Redundant power supply inputs: Enhances system security by protecting against power interruptions.

-

Advanced diagnostics: Built-in monitoring tools enable early fault detection and predictive maintenance.

-

Seamless integration with Yokogawa systems: Compatible with ProSafe-RS and CENTUM VP for unified control and safety management.

-

Proven performance record: Backed by Yokogawa’s decades of experience in automation technology.

Frequently Asked Questions (FAQ)

-

What is the key benefit of the duplexed design in the AFV10D-S41101?

It ensures continuous operation by having two independent control processors that back each other up.

-

Is the AFV10D-S41101 compatible with Yokogawa’s ProSafe-RS system?

Yes, it is specifically designed to work within the ProSafe-RS safety instrumented system.

-

What safety standards does this unit comply with?

It meets IEC 61508 SIL3, CE, and UL certifications.

-

Can this unit manage both analog and digital inputs/outputs?

Yes, it supports a broad range of both digital and analog I/O modules.

-

What are the mounting options for this control unit?

It supports panel or rack mounting depending on installation needs.

-

What is the temperature operating range of the AFV10D-S41101?

The unit reliably operates between 0°C and 55°C.

-

Does the unit feature redundant power supplies?

Yes, it includes dual 24 V DC redundant power inputs.

-

How does the system handle failure of one control channel?

Control automatically switches to the other channel without any loss of control.

-

Can this unit be monitored or controlled remotely?

Yes, Ethernet communication interfaces support remote diagnostics and control.

-

What routine maintenance is required?

Regular system health checks and software/firmware updates are recommended for optimal operation.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...