Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

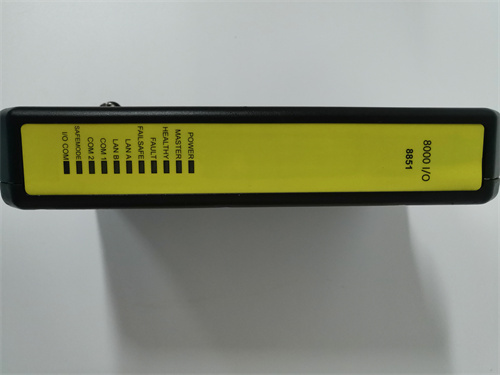

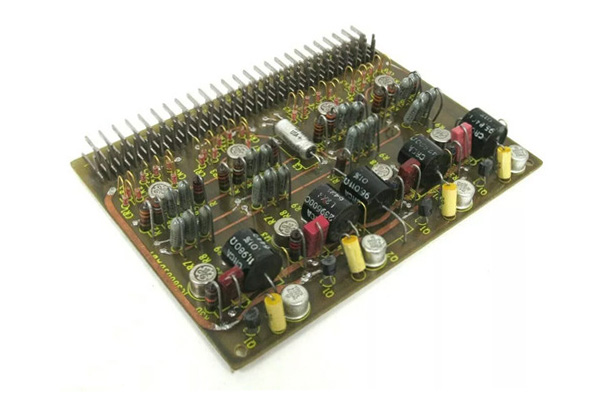

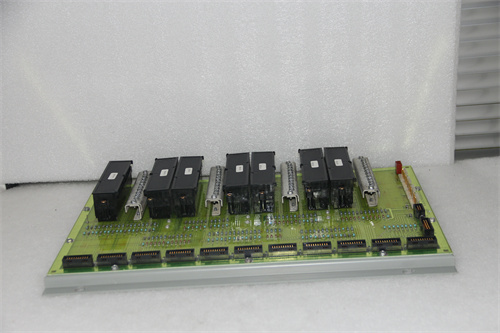

General Electric IS200AEPAH1B Printed Circuit Board

Manufacturer:GE

Product Number:IS200AEPAH1B

Product Type:Printed Circuit Board

Origin:USA

Dimensions:330 × 240 × 35 mm

Weight:1.7 kg

Views:58

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200AEPAH1B is a high-performance Exciter Power Amplifier board designed specifically for General Electric’s Mark VI and Mark VIe control systems. As a key component in generator excitation systems, this printed circuit board is responsible for providing regulated excitation current to synchronous generators. With precision amplification and signal conditioning capabilities, the AEPA board ensures that the excitation system operates smoothly, maintaining stability and efficiency across varying loads and operating conditions.

This board is built to withstand the demanding requirements of industrial environments, such as high temperatures, vibrations, and electrical noise. It comes equipped with high-quality industrial-grade components, making it suitable for long-term deployment in power generation facilities. The IS200AEPAH1B is an upgrade over its predecessors, offering refined layout optimizations and improved thermal performance.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | IS200AEPAH1B Printed Circuit Board |

| Manufacturer | General Electric (GE) |

| Function | Exciter Power Amplifier for synchronous machines |

| System Compatibility | GE Mark VI and Mark VIe Control Systems |

| Voltage Input Range | 18–36 VDC |

| Output Power | Up to 500 W (load-dependent) |

| Operating Temperature | -30°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Mounting Type | Rack-mounted, Backplane integration |

| Coating Type | Conformal-coated PCB |

| Signal Type | Analog/Digital |

| Cooling Method | Passive air convection or forced air |

| Dimensions | 330 × 240 × 35 mm |

| Weight | 1.7 kg |

| Compliance Standards | CE, RoHS, UL Recognized, ISO 9001 |

| Board Type | 6-layer industrial PCB |

| Status LEDs | Yes (for operation and fault diagnostics) |

Product Applications

The IS200AEPAH1B board serves in critical control environments where generator excitation plays a central role. Some major application areas include:

-

Power Generation Plants – Used in steam, gas, and hydro turbine excitation systems.

-

Industrial Motors – Supports excitation control for large synchronous motors.

-

Energy Backup Systems – Ensures stable operation of generator excitation during grid outages.

-

Heavy Manufacturing Plants – Integrated into control panels for large machinery requiring regulated power.

-

Oil and Gas Refineries – Installed in turbine systems to control generator output reliably.

-

Utility Companies – Applied in substations and power delivery systems for continuous excitation control.

Product Advantages

-

Seamless System Integration: Fully compatible with GE’s Mark VI and Mark VIe series, ensuring plug-and-play performance.

-

High Reliability in Harsh Conditions: Designed to perform consistently in extreme temperatures, high humidity, and industrial electrical environments.

-

Stable Excitation Output: Provides precise amplification, minimizing power fluctuation and enhancing system efficiency.

-

Diagnostic LED Indicators: Built-in visual status indicators allow for quick fault identification and reduced troubleshooting time.

-

Durable Build Quality: PCB is conformal-coated and made with high-temperature resistant materials, ideal for long operational life.

-

Field Proven: Trusted across hundreds of global installations with excellent operational feedback.

Frequently Asked Questions (FAQ)

1. What does the IS200AEPAH1B specifically control in a power plant system?

It amplifies excitation signals and regulates field current in synchronous generators, ensuring voltage stability and reliable generator performance.

2. Is this board interchangeable with IS200AEPAH1A?

While they share similar functions, revisions such as “B” and “A” may have layout or firmware differences. Consult GE documentation or an engineer before substituting.

3. Can the AEPAH1B be hot-swapped in a running system?

No, the system should be completely powered down before installing or removing this board to prevent electrical damage and personal injury.

4. What are the cooling requirements for this board?

It primarily relies on passive convection but can be installed in forced-air cooled enclosures for better performance in high-heat environments.

5. How do I detect a fault in the board?

Check the onboard LED indicators and system controller logs. Faults may include loss of output, communication errors, or voltage irregularities.

6. Can this board operate in environments with high electrical noise?

Yes, the board is engineered for industrial settings and includes shielding, conformal coating, and noise-resistant architecture to maintain performance in high-EMI conditions.

7. What maintenance does this board require?

Minimal maintenance is needed. Routine inspections for dust buildup or connector corrosion are advisable during scheduled shutdowns.

8. Does this board come with built-in protection features?

Yes, it includes current limiting, thermal protection, and built-in fault diagnostics to protect itself and connected systems.

9. Can the AEPAH1B be used outside of GE systems?

It is designed exclusively for GE Mark VI/VIe environments. Use outside these systems is not recommended or supported.

10. What maintenance procedures are recommended?

Routine visual inspections for dust, oxidation on connectors, and verification of secure mounting are sufficient. Functional diagnostics can be run through the host controller during scheduled maintenance cycles.

General Electric IS200AEPAH1B Printed Circuit Board

Manufacturer:GE

Product Number:IS200AEPAH1B

Product Type:Printed Circuit Board

Origin:USA

Dimensions:330 × 240 × 35 mm

Weight:1.7 kg

Views:58

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200AEPAH1B is a high-performance Exciter Power Amplifier board designed specifically for General Electric’s Mark VI and Mark VIe control systems. As a key component in generator excitation systems, this printed circuit board is responsible for providing regulated excitation current to synchronous generators. With precision amplification and signal conditioning capabilities, the AEPA board ensures that the excitation system operates smoothly, maintaining stability and efficiency across varying loads and operating conditions.

This board is built to withstand the demanding requirements of industrial environments, such as high temperatures, vibrations, and electrical noise. It comes equipped with high-quality industrial-grade components, making it suitable for long-term deployment in power generation facilities. The IS200AEPAH1B is an upgrade over its predecessors, offering refined layout optimizations and improved thermal performance.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | IS200AEPAH1B Printed Circuit Board |

| Manufacturer | General Electric (GE) |

| Function | Exciter Power Amplifier for synchronous machines |

| System Compatibility | GE Mark VI and Mark VIe Control Systems |

| Voltage Input Range | 18–36 VDC |

| Output Power | Up to 500 W (load-dependent) |

| Operating Temperature | -30°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Mounting Type | Rack-mounted, Backplane integration |

| Coating Type | Conformal-coated PCB |

| Signal Type | Analog/Digital |

| Cooling Method | Passive air convection or forced air |

| Dimensions | 330 × 240 × 35 mm |

| Weight | 1.7 kg |

| Compliance Standards | CE, RoHS, UL Recognized, ISO 9001 |

| Board Type | 6-layer industrial PCB |

| Status LEDs | Yes (for operation and fault diagnostics) |

Product Applications

The IS200AEPAH1B board serves in critical control environments where generator excitation plays a central role. Some major application areas include:

-

Power Generation Plants – Used in steam, gas, and hydro turbine excitation systems.

-

Industrial Motors – Supports excitation control for large synchronous motors.

-

Energy Backup Systems – Ensures stable operation of generator excitation during grid outages.

-

Heavy Manufacturing Plants – Integrated into control panels for large machinery requiring regulated power.

-

Oil and Gas Refineries – Installed in turbine systems to control generator output reliably.

-

Utility Companies – Applied in substations and power delivery systems for continuous excitation control.

Product Advantages

-

Seamless System Integration: Fully compatible with GE’s Mark VI and Mark VIe series, ensuring plug-and-play performance.

-

High Reliability in Harsh Conditions: Designed to perform consistently in extreme temperatures, high humidity, and industrial electrical environments.

-

Stable Excitation Output: Provides precise amplification, minimizing power fluctuation and enhancing system efficiency.

-

Diagnostic LED Indicators: Built-in visual status indicators allow for quick fault identification and reduced troubleshooting time.

-

Durable Build Quality: PCB is conformal-coated and made with high-temperature resistant materials, ideal for long operational life.

-

Field Proven: Trusted across hundreds of global installations with excellent operational feedback.

Frequently Asked Questions (FAQ)

1. What does the IS200AEPAH1B specifically control in a power plant system?

It amplifies excitation signals and regulates field current in synchronous generators, ensuring voltage stability and reliable generator performance.

2. Is this board interchangeable with IS200AEPAH1A?

While they share similar functions, revisions such as “B” and “A” may have layout or firmware differences. Consult GE documentation or an engineer before substituting.

3. Can the AEPAH1B be hot-swapped in a running system?

No, the system should be completely powered down before installing or removing this board to prevent electrical damage and personal injury.

4. What are the cooling requirements for this board?

It primarily relies on passive convection but can be installed in forced-air cooled enclosures for better performance in high-heat environments.

5. How do I detect a fault in the board?

Check the onboard LED indicators and system controller logs. Faults may include loss of output, communication errors, or voltage irregularities.

6. Can this board operate in environments with high electrical noise?

Yes, the board is engineered for industrial settings and includes shielding, conformal coating, and noise-resistant architecture to maintain performance in high-EMI conditions.

7. What maintenance does this board require?

Minimal maintenance is needed. Routine inspections for dust buildup or connector corrosion are advisable during scheduled shutdowns.

8. Does this board come with built-in protection features?

Yes, it includes current limiting, thermal protection, and built-in fault diagnostics to protect itself and connected systems.

9. Can the AEPAH1B be used outside of GE systems?

It is designed exclusively for GE Mark VI/VIe environments. Use outside these systems is not recommended or supported.

10. What maintenance procedures are recommended?

Routine visual inspections for dust, oxidation on connectors, and verification of secure mounting are sufficient. Functional diagnostics can be run through the host controller during scheduled maintenance cycles.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...