Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

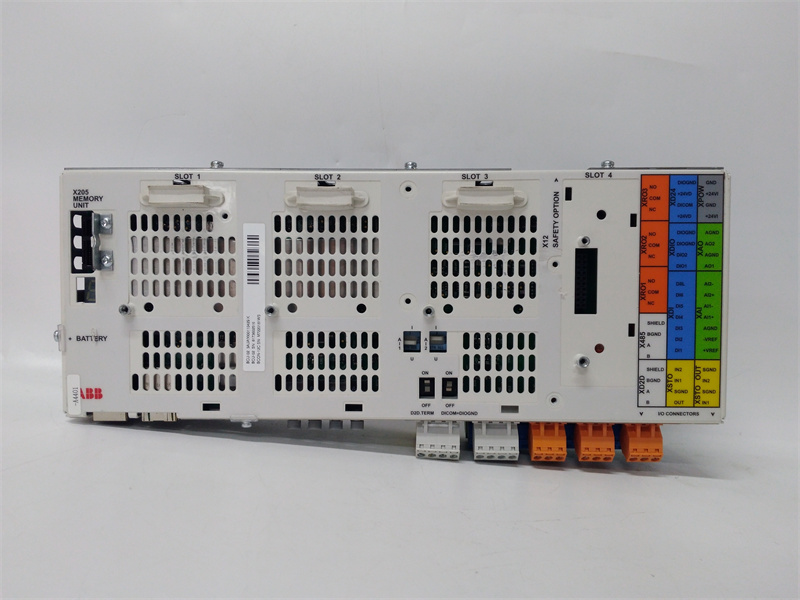

ABB 3HAC14139-1 Manipulator Harness ax 5

Manufacturer:ABB

Product Number:3HAC14139-1

Product Type:Manipulator Harness ax 5

Origin:Sweden

Dimensions:207.01 × 70 × 207.01 mm

Weight:0.54 kg

Views:27

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB 3HAC14139-1 Manipulator Harness ax 5 is a critical electrical interface component used in ABB industrial robots, specifically engineered for signal and power transmission within the Axis 5 (ax 5) of the robotic manipulator arm. This harness ensures high-reliability data and power connectivity between the robot controller and the actuator/motor components.

Designed for high-flex, repetitive-motion environments, this wiring harness plays a pivotal role in maintaining real-time responsiveness, torque control, and synchronized movement. It is purpose-built for ABB’s articulated robots—primarily those in the IRB 6000 and 6600 series—supporting factory automation tasks such as welding, material handling, and assembly.

Its robust outer sheathing, high-temperature tolerance, and secure connector integration make it ideal for harsh industrial environments, including automotive production, electronics, and metalworking industries.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | Manipulator Harness Axis 5 |

| Part Number | 3HAC14139-1 |

| Manufacturer | ABB |

| Application | Internal robot arm harness for Axis 5 |

| Compatible Robot Models | IRB 6400, IRB 6600, IRB 6700 series |

| Cable Type | Shielded high-flex control and power cable |

| Connector Type | Factory-molded industrial-grade connectors |

| Voltage Rating | Up to 600 V AC |

| Current Capacity | 10 A (typical per signal pair) |

| Outer Jacket Material | Abrasion-resistant thermoplastic elastomer (TPE) |

| Shielding | Braided copper + aluminum mylar |

| Color Coding | ABB standard axis signal color map |

| Operating Temperature | -20°C to +80°C |

| Flex Cycles (minimum) | >10 million cycles in robotic drag chain operation |

| Dimensions | 207.01 × 70 × 207.01 mm |

| Weight | 0.54 kg |

| Compliance | CE, RoHS, UL recognized |

Applications

The 3HAC14139-1 harness is used as an internal cable assembly between the robot base and Axis 5 motor/sensors. Its use spans several industries, including:

-

Automotive Industry

In spot welding and parts transfer robots within production lines.

-

Metal Fabrication

Used in plasma cutting, laser welding, and grinding robots requiring precise movement.

-

In tasks requiring accurate motion, such as soldering or PCB handling.

-

Food & Beverage Automation

Deployed in secondary packaging and high-speed sorting applications.

-

General Industrial Automation

Used in palletizing, machine tending, and pick-and-place systems with 6-axis robots.

Product Advantages

-

Precision Fit

Designed specifically for ABB’s Axis 5 wiring route, ensuring compatibility and ease of installation.

-

High-Flexibility Design

Supports continuous multi-axis movement with a high number of flex cycles.

-

Reliable Signal Transmission

Shielded cables reduce noise and interference for accurate motor and encoder control.

-

Industrial-Grade Durability

Outer sheath resists abrasion, oils, and harsh environments, extending service life.

-

Time-Saving Maintenance

Pre-terminated and labeled for plug-and-play replacement, minimizing robot downtime.

-

OEM Certified

Manufactured to ABB’s original specifications, ensuring performance and warranty integrity.

Frequently Asked Questions (FAQ)

1. What is the function of the 3HAC14139-1 harness?

It transmits power and signal between the robot controller and the motor/sensors on Axis 5 of ABB robots.

2. Which robots is it compatible with?

It is primarily used in ABB IRB 6400, IRB 6600, and IRB 6700 series industrial robots.

3. Can I use a third-party cable instead?

While technically possible, non-OEM cables may not meet ABB’s mechanical or electrical tolerances, risking failure or warranty issues.

4. How long does the harness typically last?

It is designed for over 10 million flex cycles, depending on environmental conditions and robot usage.

5. Is installation complicated?

Installation is straightforward for trained service technicians. It involves routing the harness through the arm channels and connecting the plugs.

6. Is the harness shielded?

Yes, it uses a combination of braided copper and mylar shielding for EMI protection.

7. Can it be used in cleanroom environments?

Standard versions are not rated for cleanrooms. ABB offers special cleanroom variants on request.

8. Is this a high-voltage cable?

It supports up to 600 V AC, which is standard for most industrial motors and servo systems.

9. What happens if the cable fails?

Failure may lead to Axis 5 movement errors or loss of communication with the drive.

10. How flexible is the cable under continuous robotic motion?

It is engineered for millions of flex cycles, making it suitable for continuous multi-axis robotic movement.

ABB 3HAC14139-1 Manipulator Harness ax 5

Manufacturer:ABB

Product Number:3HAC14139-1

Product Type:Manipulator Harness ax 5

Origin:Sweden

Dimensions:207.01 × 70 × 207.01 mm

Weight:0.54 kg

Views:27

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB 3HAC14139-1 Manipulator Harness ax 5 is a critical electrical interface component used in ABB industrial robots, specifically engineered for signal and power transmission within the Axis 5 (ax 5) of the robotic manipulator arm. This harness ensures high-reliability data and power connectivity between the robot controller and the actuator/motor components.

Designed for high-flex, repetitive-motion environments, this wiring harness plays a pivotal role in maintaining real-time responsiveness, torque control, and synchronized movement. It is purpose-built for ABB’s articulated robots—primarily those in the IRB 6000 and 6600 series—supporting factory automation tasks such as welding, material handling, and assembly.

Its robust outer sheathing, high-temperature tolerance, and secure connector integration make it ideal for harsh industrial environments, including automotive production, electronics, and metalworking industries.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | Manipulator Harness Axis 5 |

| Part Number | 3HAC14139-1 |

| Manufacturer | ABB |

| Application | Internal robot arm harness for Axis 5 |

| Compatible Robot Models | IRB 6400, IRB 6600, IRB 6700 series |

| Cable Type | Shielded high-flex control and power cable |

| Connector Type | Factory-molded industrial-grade connectors |

| Voltage Rating | Up to 600 V AC |

| Current Capacity | 10 A (typical per signal pair) |

| Outer Jacket Material | Abrasion-resistant thermoplastic elastomer (TPE) |

| Shielding | Braided copper + aluminum mylar |

| Color Coding | ABB standard axis signal color map |

| Operating Temperature | -20°C to +80°C |

| Flex Cycles (minimum) | >10 million cycles in robotic drag chain operation |

| Dimensions | 207.01 × 70 × 207.01 mm |

| Weight | 0.54 kg |

| Compliance | CE, RoHS, UL recognized |

Applications

The 3HAC14139-1 harness is used as an internal cable assembly between the robot base and Axis 5 motor/sensors. Its use spans several industries, including:

-

Automotive Industry

In spot welding and parts transfer robots within production lines.

-

Metal Fabrication

Used in plasma cutting, laser welding, and grinding robots requiring precise movement.

-

In tasks requiring accurate motion, such as soldering or PCB handling.

-

Food & Beverage Automation

Deployed in secondary packaging and high-speed sorting applications.

-

General Industrial Automation

Used in palletizing, machine tending, and pick-and-place systems with 6-axis robots.

Product Advantages

-

Precision Fit

Designed specifically for ABB’s Axis 5 wiring route, ensuring compatibility and ease of installation.

-

High-Flexibility Design

Supports continuous multi-axis movement with a high number of flex cycles.

-

Reliable Signal Transmission

Shielded cables reduce noise and interference for accurate motor and encoder control.

-

Industrial-Grade Durability

Outer sheath resists abrasion, oils, and harsh environments, extending service life.

-

Time-Saving Maintenance

Pre-terminated and labeled for plug-and-play replacement, minimizing robot downtime.

-

OEM Certified

Manufactured to ABB’s original specifications, ensuring performance and warranty integrity.

Frequently Asked Questions (FAQ)

1. What is the function of the 3HAC14139-1 harness?

It transmits power and signal between the robot controller and the motor/sensors on Axis 5 of ABB robots.

2. Which robots is it compatible with?

It is primarily used in ABB IRB 6400, IRB 6600, and IRB 6700 series industrial robots.

3. Can I use a third-party cable instead?

While technically possible, non-OEM cables may not meet ABB’s mechanical or electrical tolerances, risking failure or warranty issues.

4. How long does the harness typically last?

It is designed for over 10 million flex cycles, depending on environmental conditions and robot usage.

5. Is installation complicated?

Installation is straightforward for trained service technicians. It involves routing the harness through the arm channels and connecting the plugs.

6. Is the harness shielded?

Yes, it uses a combination of braided copper and mylar shielding for EMI protection.

7. Can it be used in cleanroom environments?

Standard versions are not rated for cleanrooms. ABB offers special cleanroom variants on request.

8. Is this a high-voltage cable?

It supports up to 600 V AC, which is standard for most industrial motors and servo systems.

9. What happens if the cable fails?

Failure may lead to Axis 5 movement errors or loss of communication with the drive.

10. How flexible is the cable under continuous robotic motion?

It is engineered for millions of flex cycles, making it suitable for continuous multi-axis robotic movement.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...