Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

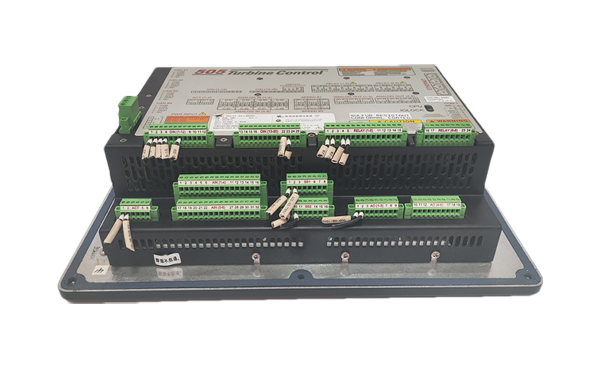

Woodward 9905-463 Digital Speed Control Module

Manufacturer:Woodward

Product Number:9905-463

Product Type:Digital Speed Control Module

Origin:USA

Dimensions:315 x 211 x 49 mm

Weight:1.59 kg

Views:33

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 9905-463 Digital Speed Control Module is a precision-engineered digital governor designed to manage the speed of prime movers such as diesel engines, gas engines, and industrial turbines. As part of Woodward’s respected 2301D-ST (Speed/Temperature) product family, this module offers advanced speed control capabilities along with temperature-based logic for optimized machinery operation.

The 9905-463 provides proportional-integral-derivative (PID) speed control, multiple configurable input/output channels, and easy communication with supervisory systems. Its digital architecture enables precise tuning, real-time diagnostics, and smooth response to varying load conditions. It is suitable for both single-engine applications and complex engine-generator systems operating in parallel or islanded modes.

Built to function in the most demanding environments, the 9905-463 maintains exceptional reliability and accuracy, making it a favored solution in power generation, oil and gas, marine, and industrial automation settings.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 9905-463 |

| Product Type | Digital Speed Control Module |

| Voltage Supply Range | 18–32 VDC |

| Power Consumption | < 15 W |

| Control Algorithm | Digital PID (Proportional, Integral, Derivative) |

| Speed Sensor Input | Magnetic Pickup (MPU), 1–32 Vrms, 2–10 kHz |

| Analog Inputs | 3 configurable inputs (0–5 V, 4–20 mA) |

| Digital Inputs | 4 configurable discrete inputs |

| Outputs | 2 actuator control outputs (PWM/0–200 mA) |

| Communication | RS-232/RS-485 (Modbus), optional CANopen |

| Operating Temperature | –40 °C to +70 °C |

| Storage Temperature | –55 °C to +85 °C |

| Humidity Tolerance | 95% RH non-condensing |

| Mounting | Panel-mounted enclosure |

| Dimensions (H × W × D) | 315 x 211 x 49 mm |

| Weight | 1.59 kg |

| Certifications | CE, UL, CSA (as applicable) |

Applications

-

Power Generation: Used for digital speed control of gensets in both islanded and grid-parallel configurations.

-

Marine Propulsion and Auxiliary Engines: Provides precision control of propulsion engines and onboard power systems.

-

Oil and Gas Operations: Controls compressors and pumps driven by engines or turbines in upstream and midstream operations.

-

Steam and Gas Turbines: Ensures stable and responsive turbine control for process industries.

-

Industrial Engines: Governs speed in critical rotating equipment such as chillers, blowers, and conveyors.

-

Backup Power Systems: Maintains speed and frequency stability in emergency generator systems.

Advantages

-

High-Precision Speed Control: PID-based digital logic enables accurate and stable engine performance.

-

Fully Programmable: Inputs and outputs are configurable to suit various application requirements.

-

Robust Communication Options: Equipped with RS-232/RS-485 Modbus communication and optional CANopen.

-

Environmental Resilience: Operates reliably in extreme temperatures and humid conditions.

-

Real-Time Diagnostics: Monitors inputs, outputs, speed, and actuator position for improved serviceability.

-

Versatile I/O: Analog and digital inputs and outputs allow integration with sensors, actuators, and safety systems.

-

Compact and Durable Design: Saves panel space while ensuring long operational life in harsh environments.

-

Enhanced Safety: Supports fault detection and shutdown procedures to protect engine and equipment.

-

Easy Integration: Compatible with a wide range of engines, actuators, and monitoring systems.

-

Global Certification: Complies with key industrial standards for safety and reliability.

Frequently Asked Questions (FAQ)

-

Q: What is the primary function of the 9905-463 module?

A: It provides digital PID-based speed control for engines and turbines in industrial and power generation applications.

-

Q: Can the 9905-463 be used in marine engine applications?

A: Yes, it is well-suited for both propulsion and auxiliary marine engine control.

-

Q: What type of sensors does it support?

A: It accepts signals from magnetic pickup (MPU) speed sensors and analog input signals.

-

Q: Does this controller support communication protocols?

A: Yes, it supports Modbus via RS-232/RS-485 and optionally CANopen for networked control.

-

Q: How many analog inputs are available?

A: It offers three configurable analog inputs for use with sensors and external signals.

-

Q: What is the size and weight of the module?

A: It measures 315 x 211 x 49 mm and weighs 1.59 kg.

-

Q: Is the control loop customizable?

A: Yes, the PID parameters are fully adjustable using configuration software.

-

Q: Does the unit include any built-in diagnostics?

A: Yes, it offers real-time monitoring of input/output status, actuator behavior, and fault conditions.

-

Q: What actuators can it drive?

A: It is compatible with Woodward actuators using PWM or current-based drive signals.

-

Q: What is the operating voltage?

A: The unit operates on a DC supply range of 18 to 32 VDC.

Woodward 9905-463 Digital Speed Control Module

Manufacturer:Woodward

Product Number:9905-463

Product Type:Digital Speed Control Module

Origin:USA

Dimensions:315 x 211 x 49 mm

Weight:1.59 kg

Views:33

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 9905-463 Digital Speed Control Module is a precision-engineered digital governor designed to manage the speed of prime movers such as diesel engines, gas engines, and industrial turbines. As part of Woodward’s respected 2301D-ST (Speed/Temperature) product family, this module offers advanced speed control capabilities along with temperature-based logic for optimized machinery operation.

The 9905-463 provides proportional-integral-derivative (PID) speed control, multiple configurable input/output channels, and easy communication with supervisory systems. Its digital architecture enables precise tuning, real-time diagnostics, and smooth response to varying load conditions. It is suitable for both single-engine applications and complex engine-generator systems operating in parallel or islanded modes.

Built to function in the most demanding environments, the 9905-463 maintains exceptional reliability and accuracy, making it a favored solution in power generation, oil and gas, marine, and industrial automation settings.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 9905-463 |

| Product Type | Digital Speed Control Module |

| Voltage Supply Range | 18–32 VDC |

| Power Consumption | < 15 W |

| Control Algorithm | Digital PID (Proportional, Integral, Derivative) |

| Speed Sensor Input | Magnetic Pickup (MPU), 1–32 Vrms, 2–10 kHz |

| Analog Inputs | 3 configurable inputs (0–5 V, 4–20 mA) |

| Digital Inputs | 4 configurable discrete inputs |

| Outputs | 2 actuator control outputs (PWM/0–200 mA) |

| Communication | RS-232/RS-485 (Modbus), optional CANopen |

| Operating Temperature | –40 °C to +70 °C |

| Storage Temperature | –55 °C to +85 °C |

| Humidity Tolerance | 95% RH non-condensing |

| Mounting | Panel-mounted enclosure |

| Dimensions (H × W × D) | 315 x 211 x 49 mm |

| Weight | 1.59 kg |

| Certifications | CE, UL, CSA (as applicable) |

Applications

-

Power Generation: Used for digital speed control of gensets in both islanded and grid-parallel configurations.

-

Marine Propulsion and Auxiliary Engines: Provides precision control of propulsion engines and onboard power systems.

-

Oil and Gas Operations: Controls compressors and pumps driven by engines or turbines in upstream and midstream operations.

-

Steam and Gas Turbines: Ensures stable and responsive turbine control for process industries.

-

Industrial Engines: Governs speed in critical rotating equipment such as chillers, blowers, and conveyors.

-

Backup Power Systems: Maintains speed and frequency stability in emergency generator systems.

Advantages

-

High-Precision Speed Control: PID-based digital logic enables accurate and stable engine performance.

-

Fully Programmable: Inputs and outputs are configurable to suit various application requirements.

-

Robust Communication Options: Equipped with RS-232/RS-485 Modbus communication and optional CANopen.

-

Environmental Resilience: Operates reliably in extreme temperatures and humid conditions.

-

Real-Time Diagnostics: Monitors inputs, outputs, speed, and actuator position for improved serviceability.

-

Versatile I/O: Analog and digital inputs and outputs allow integration with sensors, actuators, and safety systems.

-

Compact and Durable Design: Saves panel space while ensuring long operational life in harsh environments.

-

Enhanced Safety: Supports fault detection and shutdown procedures to protect engine and equipment.

-

Easy Integration: Compatible with a wide range of engines, actuators, and monitoring systems.

-

Global Certification: Complies with key industrial standards for safety and reliability.

Frequently Asked Questions (FAQ)

-

Q: What is the primary function of the 9905-463 module?

A: It provides digital PID-based speed control for engines and turbines in industrial and power generation applications.

-

Q: Can the 9905-463 be used in marine engine applications?

A: Yes, it is well-suited for both propulsion and auxiliary marine engine control.

-

Q: What type of sensors does it support?

A: It accepts signals from magnetic pickup (MPU) speed sensors and analog input signals.

-

Q: Does this controller support communication protocols?

A: Yes, it supports Modbus via RS-232/RS-485 and optionally CANopen for networked control.

-

Q: How many analog inputs are available?

A: It offers three configurable analog inputs for use with sensors and external signals.

-

Q: What is the size and weight of the module?

A: It measures 315 x 211 x 49 mm and weighs 1.59 kg.

-

Q: Is the control loop customizable?

A: Yes, the PID parameters are fully adjustable using configuration software.

-

Q: Does the unit include any built-in diagnostics?

A: Yes, it offers real-time monitoring of input/output status, actuator behavior, and fault conditions.

-

Q: What actuators can it drive?

A: It is compatible with Woodward actuators using PWM or current-based drive signals.

-

Q: What is the operating voltage?

A: The unit operates on a DC supply range of 18 to 32 VDC.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...