Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

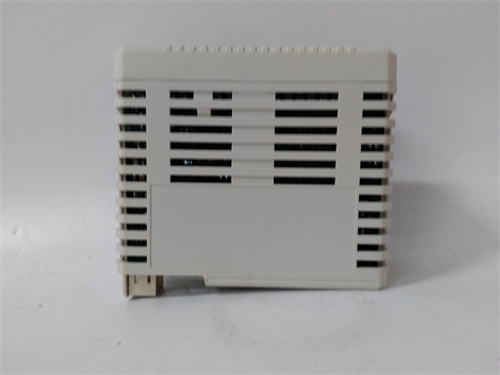

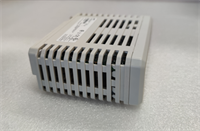

ABB PM571-ETH 1SAP130100R0170 Programmable Logic Controller

Manufacturer:ABB

Product Number:PM571-ETH 1SAP130100R0170

Product Type:Programmable Logic Controller

Origin:Sweden

Dimensions:62 × 76 × 67.5 mm

Weight:0.152 kg

Views:25

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PM571-ETH (1SAP130100R0170) is a high-performance Programmable Logic Controller (PLC) designed for advanced industrial automation applications. This controller offers robust processing power combined with versatile communication capabilities, making it suitable for complex control systems requiring precise, reliable operation.

Built with ABB’s hallmark engineering excellence, the PM571-ETH integrates seamlessly into various industrial environments. It supports Ethernet communication, enabling smooth network integration and fast data transfer. Its modular design facilitates easy scalability and maintenance, ensuring long-term operational efficiency.

This PLC is particularly favored in manufacturing lines, process automation, and infrastructure projects where high availability and precise control are critical.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | PM571-ETH 1SAP130100R0170 |

| Processor Type | ARM Cortex-M7 based, high-speed CPU |

| Memory | Program memory: 1 MB; Data memory: 512 KB |

| Communication Interfaces | Ethernet (2 ports, 10/100 Mbps) |

| Input Voltage | 24 V DC nominal |

| Digital Inputs | Up to 24 inputs (configurable via I/O modules) |

| Digital Outputs | Up to 16 outputs (configurable via I/O modules) |

| Analog Inputs | Supported via expansion modules |

| Operating Temperature Range | -20°C to +60°C |

| Dimensions (HxWxD) | 62 × 76 × 67.5 mm |

| Weight | 0.152 kg |

| Protection Class | IP20 |

| Programming Software | ABB Automation Builder / IEC 61131-3 compatible |

| Standards Compliance | CE, UL, cUL, RoHS |

Product Applications

The ABB PM571-ETH PLC is engineered for a broad range of industrial automation applications, including but not limited to:

-

Manufacturing Automation: Control of assembly lines, robotic systems, and automated machinery for enhanced production efficiency.

-

Process Control: Monitoring and managing continuous processes in industries such as chemical, food and beverage, and pharmaceuticals.

-

Infrastructure Management: Automation of HVAC systems, water treatment plants, and building management systems.

-

Energy Sector: Control systems for power generation and distribution networks.

-

Material Handling: Automation of conveyors, sorting systems, and packaging machinery.

-

Machine Control: Integration in CNC machines, presses, and other industrial equipment requiring precise control logic.

Product Advantages

-

High Performance: The ARM Cortex-M7 CPU delivers fast execution of complex control algorithms, improving system responsiveness.

-

Robust Connectivity: Dual Ethernet ports support daisy-chaining and redundancy, ensuring reliable network communication.

-

Modular Flexibility: Supports a variety of I/O expansion modules to tailor the system to specific application needs.

-

Ease of Programming: Compatible with ABB Automation Builder software and standard IEC 61131-3 programming languages, facilitating user-friendly programming and maintenance.

-

Compact Design: Small footprint allows installation in limited-space control cabinets.

-

Reliability: Designed to operate under harsh industrial conditions, including wide temperature ranges and electrical noise environments.

-

Scalability: Easily expandable as system complexity grows, protecting investment over time.

-

Energy Efficient: Low power consumption reduces operational costs.

-

Compliance and Safety: Meets international standards for industrial automation safety and interoperability.

Frequently Asked Questions (FAQ)

-

Q: What programming languages are supported by the PM571-ETH?

A: The controller supports IEC 61131-3 standard languages, including Ladder Diagram (LD), Structured Text (ST), Function Block Diagram (FBD), Instruction List (IL), and Sequential Function Chart (SFC).

-

Q: Can the PM571-ETH operate in hazardous environments?

A: While the PM571-ETH is robust, it is designed primarily for standard industrial environments. For hazardous locations, additional protective enclosures or specific certifications may be necessary.

-

Q: What kind of network protocols does the PM571-ETH support?

A: The device supports Ethernet/IP and Modbus TCP/IP protocols, facilitating integration with a wide range of industrial networks.

-

Q: How is the PM571-ETH powered?

A: It requires a 24 V DC power supply, which is typical for industrial control devices.

-

Q: Is remote programming and monitoring supported?

A: Yes, via Ethernet communication, users can program and monitor the PLC remotely using ABB’s software tools.

-

Q: What is the typical lifespan of the PM571-ETH?

A: With proper maintenance, the PM571-ETH is expected to operate reliably for 10+ years in industrial conditions.

-

Q: Are expansion modules available for additional I/O?

A: Yes, ABB offers a wide range of compatible I/O modules that can be connected to the PM571-ETH for tailored system configuration.

-

Q: How does the controller handle power failures?

A: The PM571-ETH includes non-volatile memory to retain programs and data during power outages. For critical applications, external UPS solutions are recommended.

-

Q: What is the maximum program size the PM571-ETH can handle?

A: The controller has 1 MB of program memory, which is sufficient for most mid-scale industrial automation projects.

-

Q: Is there built-in diagnostics for troubleshooting?

A: Yes, the controller provides diagnostic functions accessible via the programming software to aid in troubleshooting and maintenance.

ABB PM571-ETH 1SAP130100R0170 Programmable Logic Controller

Manufacturer:ABB

Product Number:PM571-ETH 1SAP130100R0170

Product Type:Programmable Logic Controller

Origin:Sweden

Dimensions:62 × 76 × 67.5 mm

Weight:0.152 kg

Views:25

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PM571-ETH (1SAP130100R0170) is a high-performance Programmable Logic Controller (PLC) designed for advanced industrial automation applications. This controller offers robust processing power combined with versatile communication capabilities, making it suitable for complex control systems requiring precise, reliable operation.

Built with ABB’s hallmark engineering excellence, the PM571-ETH integrates seamlessly into various industrial environments. It supports Ethernet communication, enabling smooth network integration and fast data transfer. Its modular design facilitates easy scalability and maintenance, ensuring long-term operational efficiency.

This PLC is particularly favored in manufacturing lines, process automation, and infrastructure projects where high availability and precise control are critical.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | PM571-ETH 1SAP130100R0170 |

| Processor Type | ARM Cortex-M7 based, high-speed CPU |

| Memory | Program memory: 1 MB; Data memory: 512 KB |

| Communication Interfaces | Ethernet (2 ports, 10/100 Mbps) |

| Input Voltage | 24 V DC nominal |

| Digital Inputs | Up to 24 inputs (configurable via I/O modules) |

| Digital Outputs | Up to 16 outputs (configurable via I/O modules) |

| Analog Inputs | Supported via expansion modules |

| Operating Temperature Range | -20°C to +60°C |

| Dimensions (HxWxD) | 62 × 76 × 67.5 mm |

| Weight | 0.152 kg |

| Protection Class | IP20 |

| Programming Software | ABB Automation Builder / IEC 61131-3 compatible |

| Standards Compliance | CE, UL, cUL, RoHS |

Product Applications

The ABB PM571-ETH PLC is engineered for a broad range of industrial automation applications, including but not limited to:

-

Manufacturing Automation: Control of assembly lines, robotic systems, and automated machinery for enhanced production efficiency.

-

Process Control: Monitoring and managing continuous processes in industries such as chemical, food and beverage, and pharmaceuticals.

-

Infrastructure Management: Automation of HVAC systems, water treatment plants, and building management systems.

-

Energy Sector: Control systems for power generation and distribution networks.

-

Material Handling: Automation of conveyors, sorting systems, and packaging machinery.

-

Machine Control: Integration in CNC machines, presses, and other industrial equipment requiring precise control logic.

Product Advantages

-

High Performance: The ARM Cortex-M7 CPU delivers fast execution of complex control algorithms, improving system responsiveness.

-

Robust Connectivity: Dual Ethernet ports support daisy-chaining and redundancy, ensuring reliable network communication.

-

Modular Flexibility: Supports a variety of I/O expansion modules to tailor the system to specific application needs.

-

Ease of Programming: Compatible with ABB Automation Builder software and standard IEC 61131-3 programming languages, facilitating user-friendly programming and maintenance.

-

Compact Design: Small footprint allows installation in limited-space control cabinets.

-

Reliability: Designed to operate under harsh industrial conditions, including wide temperature ranges and electrical noise environments.

-

Scalability: Easily expandable as system complexity grows, protecting investment over time.

-

Energy Efficient: Low power consumption reduces operational costs.

-

Compliance and Safety: Meets international standards for industrial automation safety and interoperability.

Frequently Asked Questions (FAQ)

-

Q: What programming languages are supported by the PM571-ETH?

A: The controller supports IEC 61131-3 standard languages, including Ladder Diagram (LD), Structured Text (ST), Function Block Diagram (FBD), Instruction List (IL), and Sequential Function Chart (SFC).

-

Q: Can the PM571-ETH operate in hazardous environments?

A: While the PM571-ETH is robust, it is designed primarily for standard industrial environments. For hazardous locations, additional protective enclosures or specific certifications may be necessary.

-

Q: What kind of network protocols does the PM571-ETH support?

A: The device supports Ethernet/IP and Modbus TCP/IP protocols, facilitating integration with a wide range of industrial networks.

-

Q: How is the PM571-ETH powered?

A: It requires a 24 V DC power supply, which is typical for industrial control devices.

-

Q: Is remote programming and monitoring supported?

A: Yes, via Ethernet communication, users can program and monitor the PLC remotely using ABB’s software tools.

-

Q: What is the typical lifespan of the PM571-ETH?

A: With proper maintenance, the PM571-ETH is expected to operate reliably for 10+ years in industrial conditions.

-

Q: Are expansion modules available for additional I/O?

A: Yes, ABB offers a wide range of compatible I/O modules that can be connected to the PM571-ETH for tailored system configuration.

-

Q: How does the controller handle power failures?

A: The PM571-ETH includes non-volatile memory to retain programs and data during power outages. For critical applications, external UPS solutions are recommended.

-

Q: What is the maximum program size the PM571-ETH can handle?

A: The controller has 1 MB of program memory, which is sufficient for most mid-scale industrial automation projects.

-

Q: Is there built-in diagnostics for troubleshooting?

A: Yes, the controller provides diagnostic functions accessible via the programming software to aid in troubleshooting and maintenance.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...