Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

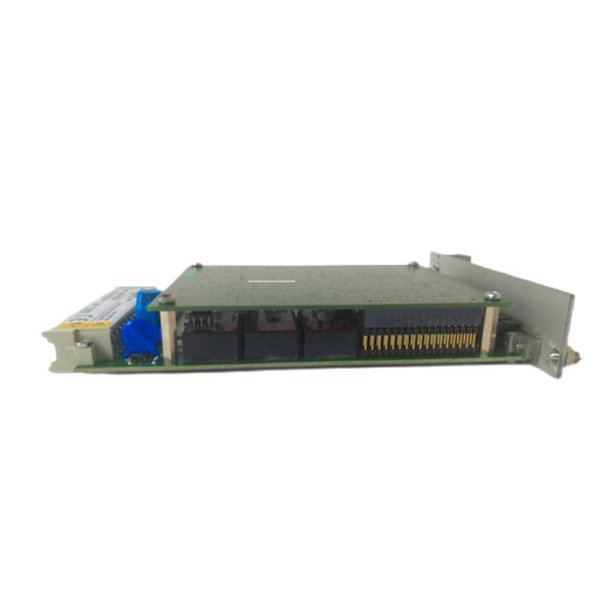

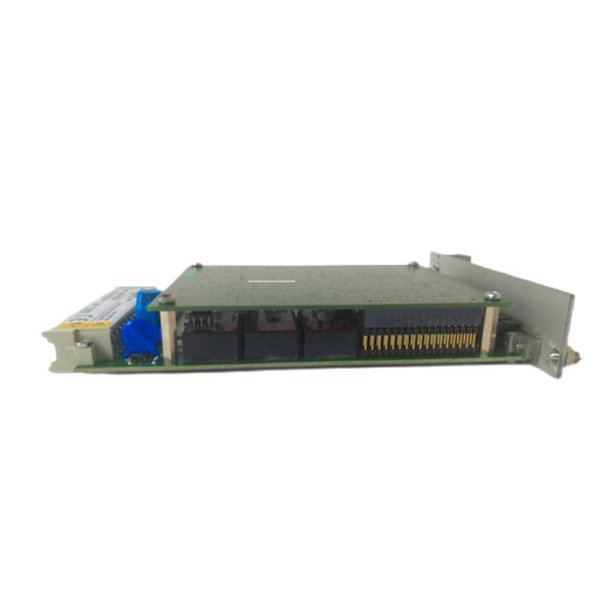

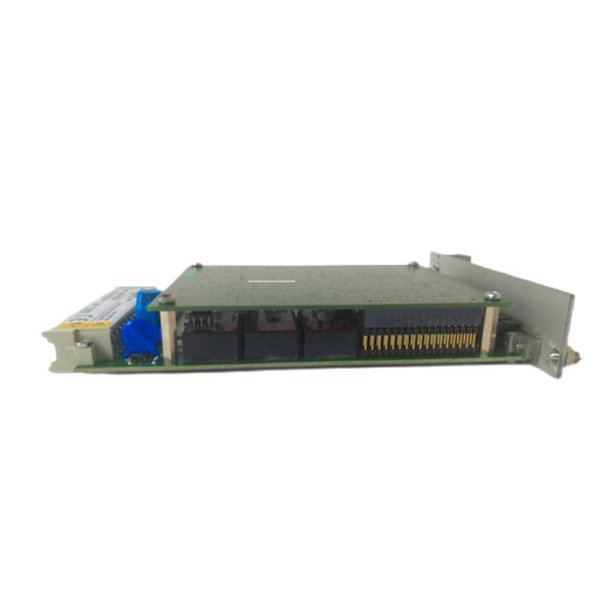

Epro MMS6220 9100-00009n Dual Channel Shaft Eccentricity Monitor

Manufacturer:Epro

Product Number:MMS6220 9100-00009n

Product Type:Dual Channel Shaft Eccentricity Monitor

Origin:Germany

Dimensions:30 x 128.4 x 160 mm

Weight:0.32 kg

Views:69

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Epro MMS6220 9100-00009N is a dual-channel shaft eccentricity monitor designed for the precise measurement of shaft eccentricity in rotating machinery. The monitor detects the deviation of the shaft’s rotational axis from the centerline of the bearing, which is crucial for preventing excessive wear, vibration, or failure in rotating equipment. This device is especially important for critical machinery such as turbines, motors, pumps, and compressors, where the alignment of rotating shafts is vital for optimal performance and longevity.

With its robust design and advanced capabilities, the Epro MMS6220 helps operators ensure the continuous monitoring of shaft health, preventing potential catastrophic failures and reducing downtime. Its dual-channel monitoring allows for the detection of eccentricity on two shafts simultaneously, making it an efficient solution for complex machinery setups.

Product Specifications

The following table outlines the key specifications for the Epro MMS6220 9100-00009N Dual Channel Shaft Eccentricity Monitor:

| Parameter | Specification |

|---|---|

| Input Channels | 2 Channels (Dual Channel Monitoring) |

| Shaft Eccentricity Range | 0.1 to 5 mm (measuring shaft deviation from centerline) |

| Output Signal | 4-20 mA (current output for each channel) |

| Power Supply | 24 V DC ± 20% |

| Operating Temperature | -20°C to +60°C (-4°F to +140°F) |

| Humidity | 5% to 95% RH (non-condensing) |

| Dimensions | 30 x 128.4 x 160 mm |

| Weight | 0.32 kg |

| Mounting | Wall or panel mountable |

| Environmental Protection | IP65 (dust-tight and water-resistant) |

| Communication Interface | Modbus RTU (RS485) for remote integration and monitoring |

| Alarm Outputs | 2 relay outputs for alarm and warning |

| Measurement Resolution | 0.01 mm |

| Certifications | CE, UL, RoHS |

Product Applications

The Epro MMS6220 9100-00009N is ideal for use in environments where precise alignment of rotating shafts is critical to the operation of machinery. Some common applications include:

- Power Generation: Monitoring turbine shafts for eccentricity and imbalance.

- Oil & Gas: Ensuring the alignment of shafts in pumps, motors, and compressors.

- Manufacturing: Detecting misalignment in production equipment such as conveyors, motors, and mills.

- Mining: Preventing shaft wear and failure in crushers, mills, and other heavy-duty machinery.

- Water Treatment: Ensuring proper alignment in pumps and fans.

- Cement and Steel Industries: Monitoring and controlling shaft eccentricity in rotary kilns, mills, and other equipment.

Product Advantages

The Epro MMS6220 9100-00009N offers several key advantages that enhance its appeal in industrial applications:

- Dual Channel Monitoring: Ability to monitor two shafts simultaneously, making it ideal for complex machinery setups.

- Precise Eccentricity Measurement: Capable of detecting even slight shaft misalignments with a resolution of 0.01 mm.

- Early Fault Detection: Identifies issues before they result in costly repairs or downtime, ensuring operational continuity.

- Real-time Monitoring: Provides continuous feedback, enabling proactive maintenance and system adjustments.

- Modbus RTU Communication: Offers easy integration with existing industrial control systems for remote monitoring and diagnostics.

- Robust Design: The IP65 rating ensures the monitor is dust-tight and water-resistant, perfect for use in harsh industrial environments.

- Cost-effective Maintenance: By preventing shaft failure and wear, the device helps reduce maintenance costs and extends machinery lifespan.

- Flexible Mounting Options: Can be mounted on walls or panels, offering installation flexibility in various locations.

Epro MMS6220 9100-00009n Dual Channel Shaft Eccentricity Monitor

Manufacturer:Epro

Product Number:MMS6220 9100-00009n

Product Type:Dual Channel Shaft Eccentricity Monitor

Origin:Germany

Dimensions:30 x 128.4 x 160 mm

Weight:0.32 kg

Views:69

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Epro MMS6220 9100-00009N is a dual-channel shaft eccentricity monitor designed for the precise measurement of shaft eccentricity in rotating machinery. The monitor detects the deviation of the shaft’s rotational axis from the centerline of the bearing, which is crucial for preventing excessive wear, vibration, or failure in rotating equipment. This device is especially important for critical machinery such as turbines, motors, pumps, and compressors, where the alignment of rotating shafts is vital for optimal performance and longevity.

With its robust design and advanced capabilities, the Epro MMS6220 helps operators ensure the continuous monitoring of shaft health, preventing potential catastrophic failures and reducing downtime. Its dual-channel monitoring allows for the detection of eccentricity on two shafts simultaneously, making it an efficient solution for complex machinery setups.

Product Specifications

The following table outlines the key specifications for the Epro MMS6220 9100-00009N Dual Channel Shaft Eccentricity Monitor:

| Parameter | Specification |

|---|---|

| Input Channels | 2 Channels (Dual Channel Monitoring) |

| Shaft Eccentricity Range | 0.1 to 5 mm (measuring shaft deviation from centerline) |

| Output Signal | 4-20 mA (current output for each channel) |

| Power Supply | 24 V DC ± 20% |

| Operating Temperature | -20°C to +60°C (-4°F to +140°F) |

| Humidity | 5% to 95% RH (non-condensing) |

| Dimensions | 30 x 128.4 x 160 mm |

| Weight | 0.32 kg |

| Mounting | Wall or panel mountable |

| Environmental Protection | IP65 (dust-tight and water-resistant) |

| Communication Interface | Modbus RTU (RS485) for remote integration and monitoring |

| Alarm Outputs | 2 relay outputs for alarm and warning |

| Measurement Resolution | 0.01 mm |

| Certifications | CE, UL, RoHS |

Product Applications

The Epro MMS6220 9100-00009N is ideal for use in environments where precise alignment of rotating shafts is critical to the operation of machinery. Some common applications include:

- Power Generation: Monitoring turbine shafts for eccentricity and imbalance.

- Oil & Gas: Ensuring the alignment of shafts in pumps, motors, and compressors.

- Manufacturing: Detecting misalignment in production equipment such as conveyors, motors, and mills.

- Mining: Preventing shaft wear and failure in crushers, mills, and other heavy-duty machinery.

- Water Treatment: Ensuring proper alignment in pumps and fans.

- Cement and Steel Industries: Monitoring and controlling shaft eccentricity in rotary kilns, mills, and other equipment.

Product Advantages

The Epro MMS6220 9100-00009N offers several key advantages that enhance its appeal in industrial applications:

- Dual Channel Monitoring: Ability to monitor two shafts simultaneously, making it ideal for complex machinery setups.

- Precise Eccentricity Measurement: Capable of detecting even slight shaft misalignments with a resolution of 0.01 mm.

- Early Fault Detection: Identifies issues before they result in costly repairs or downtime, ensuring operational continuity.

- Real-time Monitoring: Provides continuous feedback, enabling proactive maintenance and system adjustments.

- Modbus RTU Communication: Offers easy integration with existing industrial control systems for remote monitoring and diagnostics.

- Robust Design: The IP65 rating ensures the monitor is dust-tight and water-resistant, perfect for use in harsh industrial environments.

- Cost-effective Maintenance: By preventing shaft failure and wear, the device helps reduce maintenance costs and extends machinery lifespan.

- Flexible Mounting Options: Can be mounted on walls or panels, offering installation flexibility in various locations.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...