Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

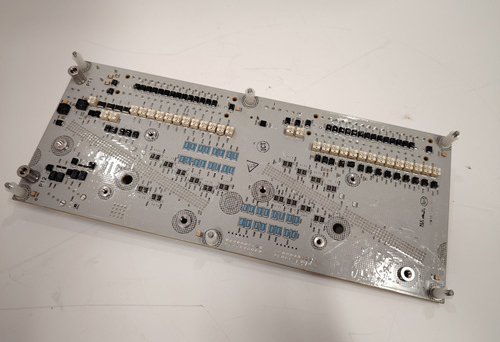

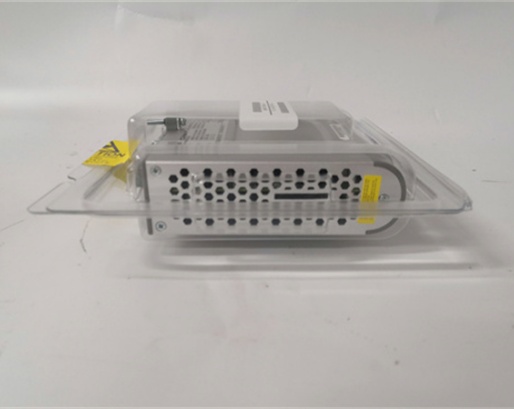

Honeywell 900R04-0200 4 Slot I/O Slot Rack

Manufacturer:Honeywell

Product Number:900R04-0200

Product Type:4 Slot I/O Slot Rack

Origin:USA

Dimensions:137 x 266.7 x 151.7 mm

Weight:2.104 kg

Views:57

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900R04-0200 4 Slot I/O Slot Rack is a modular I/O chassis designed for the HC900 Hybrid Controller and other Honeywell process automation systems. It provides a robust and flexible platform for housing digital and analog input/output modules, enabling streamlined integration of process control devices into centralized control architectures.

Designed for industrial environments, the 4-slot I/O rack ensures reliable electrical connections, secure mounting of modules, and effective communication between the I/O modules and the HC900 controller. This rack is widely used in industries requiring high system availability, real-time monitoring, and centralized control of multiple field devices.

Product Parameters

| Parameter | Specification |

|---|---|

| Product Model | Honeywell 900R04-0200 |

| Series | HC900 I/O Rack |

| Slot Count | 4 Slots for I/O modules |

| Supported Modules | Digital Input, Digital Output, Analog Input, Analog Output modules |

| Backplane Communication | High-speed communication bus to HC900 CPU |

| Power Supply | 24 VDC nominal via system backplane |

| Maximum Current per Slot | 2 A |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -20°C to +70°C |

| Relative Humidity | 5% – 95% non-condensing |

| Mounting Type | DIN-rail or panel mount |

| Dimensions | 137 x 266.7 x 151.7 mm |

| Weight | 2.104 kg |

| Certifications | CE, UL, RoHS compliant |

Product Applications

-

Process Automation – Centralizes digital and analog I/O modules for coordinated control of process equipment.

-

Water and Wastewater Treatment – Interfaces with pumps, valves, and chemical dosing systems.

-

Oil & Gas Facilities – Connects field sensors and actuators to the HC900 control system for safe and efficient operations.

-

Chemical and Pharmaceutical Production – Houses I/O modules for precise process measurement and control.

-

Power Generation – Enables distributed monitoring and control of auxiliary equipment.

-

Manufacturing Automation – Provides modular expansion capability for machine and line automation.

Product Advantages

-

Modular Design – Supports flexible installation and easy future expansion with additional I/O modules.

-

High Reliability – Industrial-grade design ensures consistent performance in harsh environments.

-

Seamless Integration – Fully compatible with HC900 controllers and communication protocols.

-

Efficient Space Usage – Four slots in a compact rack allow efficient utilization of cabinet space.

-

Rapid Maintenance – Hot-swappable modules reduce downtime during maintenance.

-

Real-Time Performance – High-speed backplane ensures low-latency communication with the controller.

-

Versatile Mounting – DIN-rail or panel mounting options simplify installation in diverse setups.

-

Safe and Secure Connections – Locking connectors prevent module disconnections and signal errors.

FAQ

-

What types of I/O modules can be installed in the 900R04-0200?

It supports digital input, digital output, analog input, and analog output modules compatible with HC900.

-

Is the rack hot-swappable?

Yes, I/O modules can be replaced without powering down the system when used with appropriate HC900 CPU configurations.

-

How does the rack communicate with the HC900 controller?

Communication occurs via a high-speed backplane that ensures real-time data transfer between modules and CPU.

-

Can multiple racks be connected in one system?

Yes, multiple 4-slot racks can be connected to expand total I/O capacity.

-

What is the maximum current per slot?

Each slot supports up to 2 A of current for connected I/O modules.

-

Does the rack require a separate power supply?

No, power is supplied via the system backplane from the HC900 controller.

-

Can the rack be mounted in standard industrial cabinets?

Yes, it supports both DIN-rail and panel mounting options.

-

Does it support analog signal modules?

Yes, the rack is fully compatible with analog input/output modules for voltage and current signals.

-

Are there any diagnostic features for the rack itself?

Yes, module status LEDs and backplane fault indicators assist in troubleshooting.

-

Can the rack be used in environments with high humidity or dust?

Yes, it operates reliably in 5%–95% non-condensing humidity environments typical in industrial settings.

Honeywell 900R04-0200 4 Slot I/O Slot Rack

Manufacturer:Honeywell

Product Number:900R04-0200

Product Type:4 Slot I/O Slot Rack

Origin:USA

Dimensions:137 x 266.7 x 151.7 mm

Weight:2.104 kg

Views:57

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900R04-0200 4 Slot I/O Slot Rack is a modular I/O chassis designed for the HC900 Hybrid Controller and other Honeywell process automation systems. It provides a robust and flexible platform for housing digital and analog input/output modules, enabling streamlined integration of process control devices into centralized control architectures.

Designed for industrial environments, the 4-slot I/O rack ensures reliable electrical connections, secure mounting of modules, and effective communication between the I/O modules and the HC900 controller. This rack is widely used in industries requiring high system availability, real-time monitoring, and centralized control of multiple field devices.

Product Parameters

| Parameter | Specification |

|---|---|

| Product Model | Honeywell 900R04-0200 |

| Series | HC900 I/O Rack |

| Slot Count | 4 Slots for I/O modules |

| Supported Modules | Digital Input, Digital Output, Analog Input, Analog Output modules |

| Backplane Communication | High-speed communication bus to HC900 CPU |

| Power Supply | 24 VDC nominal via system backplane |

| Maximum Current per Slot | 2 A |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -20°C to +70°C |

| Relative Humidity | 5% – 95% non-condensing |

| Mounting Type | DIN-rail or panel mount |

| Dimensions | 137 x 266.7 x 151.7 mm |

| Weight | 2.104 kg |

| Certifications | CE, UL, RoHS compliant |

Product Applications

-

Process Automation – Centralizes digital and analog I/O modules for coordinated control of process equipment.

-

Water and Wastewater Treatment – Interfaces with pumps, valves, and chemical dosing systems.

-

Oil & Gas Facilities – Connects field sensors and actuators to the HC900 control system for safe and efficient operations.

-

Chemical and Pharmaceutical Production – Houses I/O modules for precise process measurement and control.

-

Power Generation – Enables distributed monitoring and control of auxiliary equipment.

-

Manufacturing Automation – Provides modular expansion capability for machine and line automation.

Product Advantages

-

Modular Design – Supports flexible installation and easy future expansion with additional I/O modules.

-

High Reliability – Industrial-grade design ensures consistent performance in harsh environments.

-

Seamless Integration – Fully compatible with HC900 controllers and communication protocols.

-

Efficient Space Usage – Four slots in a compact rack allow efficient utilization of cabinet space.

-

Rapid Maintenance – Hot-swappable modules reduce downtime during maintenance.

-

Real-Time Performance – High-speed backplane ensures low-latency communication with the controller.

-

Versatile Mounting – DIN-rail or panel mounting options simplify installation in diverse setups.

-

Safe and Secure Connections – Locking connectors prevent module disconnections and signal errors.

FAQ

-

What types of I/O modules can be installed in the 900R04-0200?

It supports digital input, digital output, analog input, and analog output modules compatible with HC900.

-

Is the rack hot-swappable?

Yes, I/O modules can be replaced without powering down the system when used with appropriate HC900 CPU configurations.

-

How does the rack communicate with the HC900 controller?

Communication occurs via a high-speed backplane that ensures real-time data transfer between modules and CPU.

-

Can multiple racks be connected in one system?

Yes, multiple 4-slot racks can be connected to expand total I/O capacity.

-

What is the maximum current per slot?

Each slot supports up to 2 A of current for connected I/O modules.

-

Does the rack require a separate power supply?

No, power is supplied via the system backplane from the HC900 controller.

-

Can the rack be mounted in standard industrial cabinets?

Yes, it supports both DIN-rail and panel mounting options.

-

Does it support analog signal modules?

Yes, the rack is fully compatible with analog input/output modules for voltage and current signals.

-

Are there any diagnostic features for the rack itself?

Yes, module status LEDs and backplane fault indicators assist in troubleshooting.

-

Can the rack be used in environments with high humidity or dust?

Yes, it operates reliably in 5%–95% non-condensing humidity environments typical in industrial settings.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...