Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

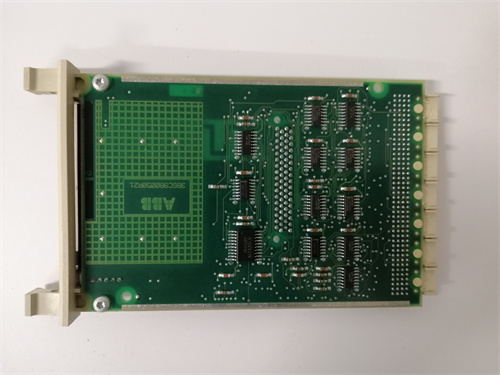

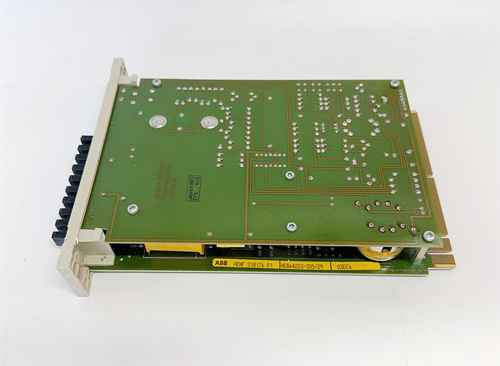

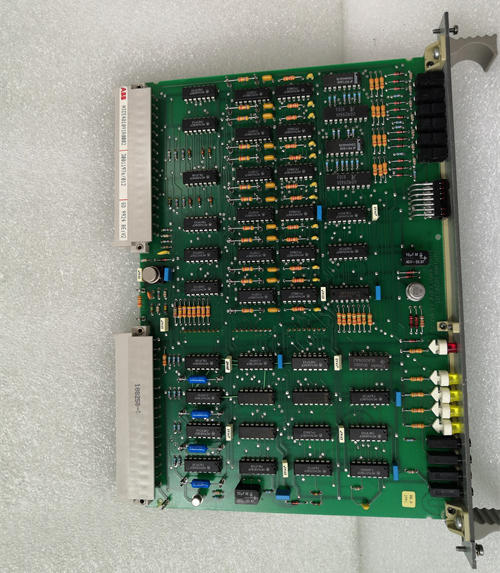

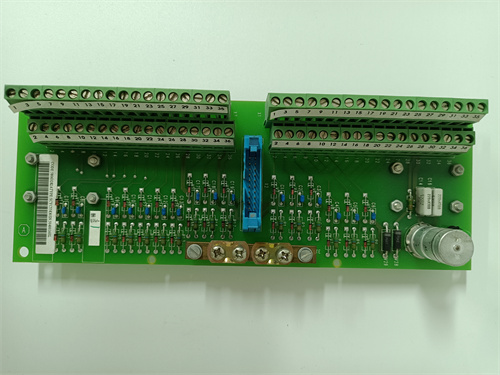

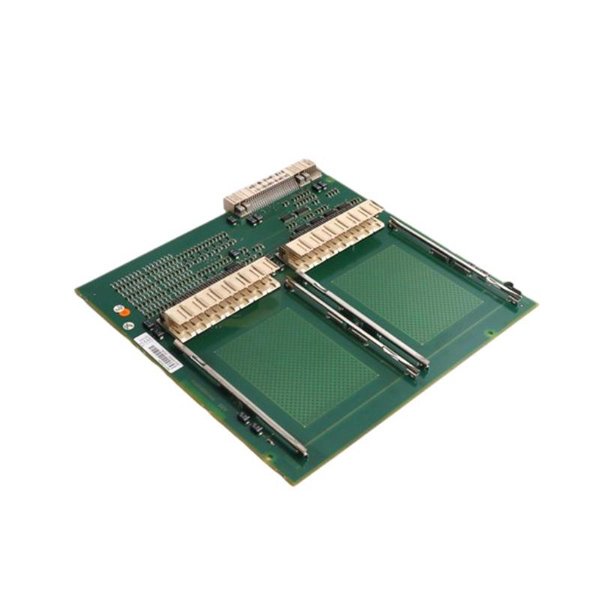

ABB PM154 3BSE003645R1 CPU Board Card

Manufacturer:ABB

Product Number:PM154 3BSE003645R1

Product Type:CPU Board Card

Origin:Sweden

Dimensions:24 × 125 × 120 mm

Weight:0.35 kg

Views:29

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

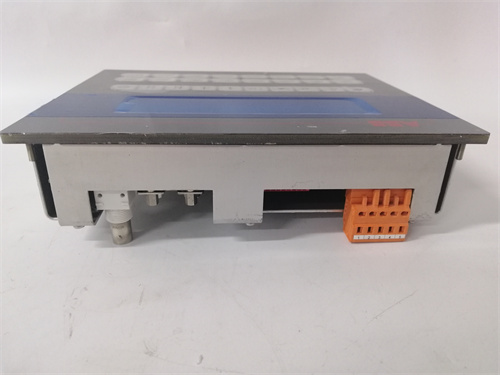

The ABB PM154 3BSE003645R1 is an advanced CPU board card used in the Advant Controller 31 series, serving as the processing core of a distributed control system (DCS). This module is designed for handling complex control logic, supporting a wide range of industrial automation functions across different sectors. As an upgraded version within the PM15x series, the PM154 offers improved processing power, memory capacity, and communication capabilities, ensuring optimal performance in both legacy and modern control environments.

This CPU module is engineered for high-speed real-time execution of automation tasks, interfacing with various I/O modules, and facilitating reliable system communication over fieldbuses like Advant Fieldbus 100. It supports configuration, diagnostics, and control with minimal downtime, making it a preferred choice in mission-critical operations.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | PM154 |

| Part Number | 3BSE003645R1 |

| Product Type | CPU Board / Central Processing Module |

| System Compatibility | Advant Controller 31 Series |

| Processor | High-speed 32-bit embedded processor |

| RAM Memory | 2 MB |

| Flash Memory | 1 MB |

| Supported Protocols | Advant Fieldbus 100, RS232, MODBUS |

| Execution Time | ≤ 1 ms per 1K instructions |

| Communication Ports | RS232, RS485, Advant Fieldbus |

| I/O Integration | Through S800 I/O or compatible modules |

| Mounting Method | DIN Rail or Rack Mounting |

| Operating Voltage | 5 VDC (supplied through base unit) |

| Power Consumption | Approx. 3.5 W |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5%–95% non-condensing |

| Protection Rating | IP20 |

| Dimensions (L × W × H) | 24 × 125 × 120 mm |

| Weight | 0.35 kg |

Applications

The ABB PM154 3BSE003645R1 is used across various industrial sectors due to its high reliability and performance capabilities:

-

Oil & Gas Industry – Used for pipeline control, compressor stations, and process safety systems.

-

Power Generation – Governs turbine control, boiler management, and auxiliary systems.

-

Metallurgy and Steel – Controls process furnaces, rolling mills, and automation lines.

-

Food & Beverage Processing – Handles batch processing, packaging, and conveyor control.

-

Pharmaceutical Manufacturing – Ensures GMP-compliant automation and data logging.

-

Water and Wastewater Treatment – Regulates valves, pumps, and chemical dosing systems.

Product Advantages

-

Enhanced Processing Capabilities – Delivers fast execution times for complex control logic.

-

High Memory Capacity – Offers larger RAM and flash than previous PM15x models, enabling robust program handling.

-

Multi-Protocol Communication – Built-in support for fieldbus communication ensures interoperability with various subsystems.

-

Compact Modular Design – Space-saving construction suitable for control cabinets and tight enclosures.

-

Advanced Diagnostics – Status LEDs and software-based tools provide real-time health and performance data.

-

Long-Term Availability – Part of ABB’s sustained product line, with long service life and ongoing support.

-

Scalable Architecture – Easily integrates with additional modules, supporting future expansion.

-

Secure and Stable Operation – Designed for continuous industrial operation with high EMI/RFI immunity.

-

Easy Integration – Compatible with standard ABB engineering tools for development and deployment.

-

Backward Compatibility – Designed to replace older PM15x modules without major system reconfiguration.

Frequently Asked Questions (FAQ)

-

What distinguishes the PM154 from the PM152 or PM151 modules?

The PM154 has a faster processor, increased memory, and improved communication interfaces, making it more suitable for demanding applications.

-

Which tools are used to configure and monitor the PM154?

ABB Control Builder and Composer tools are used for programming, diagnostics, and firmware updates.

-

Does PM154 support hot-swapping or online configuration?

While the CPU module itself is not hot-swappable, configuration changes can often be made without shutting down the entire system, depending on setup.

-

Is the PM154 suitable for high-speed data acquisition?

Yes, its enhanced processing and memory make it capable of managing high-frequency I/O operations and real-time data handling.

-

Can this CPU communicate with third-party devices?

Yes, using standard protocols like MODBUS or serial communication, it can interface with non-ABB equipment.

-

How is firmware managed for the PM154?

Firmware updates are managed through ABB’s software suite, typically via RS232 or fieldbus connections.

-

What’s the average lifespan of this module in industrial use?

Under normal operating conditions, it can function reliably for over 10 years with periodic maintenance.

-

Are there any specific grounding or shielding requirements?

Yes, for optimal performance, proper electrical grounding and shielding should be implemented as per ABB guidelines.

-

What happens during a CPU fault or failure?

The system transitions to a safe state, and diagnostics indicators or software logs help identify and correct the issue.

-

Is the PM154 certified for use in hazardous or safety-critical areas?

It is not inherently SIL-rated, but it can be part of a certified control system when integrated with appropriate safety components.

ABB PM154 3BSE003645R1 CPU Board Card

Manufacturer:ABB

Product Number:PM154 3BSE003645R1

Product Type:CPU Board Card

Origin:Sweden

Dimensions:24 × 125 × 120 mm

Weight:0.35 kg

Views:29

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PM154 3BSE003645R1 is an advanced CPU board card used in the Advant Controller 31 series, serving as the processing core of a distributed control system (DCS). This module is designed for handling complex control logic, supporting a wide range of industrial automation functions across different sectors. As an upgraded version within the PM15x series, the PM154 offers improved processing power, memory capacity, and communication capabilities, ensuring optimal performance in both legacy and modern control environments.

This CPU module is engineered for high-speed real-time execution of automation tasks, interfacing with various I/O modules, and facilitating reliable system communication over fieldbuses like Advant Fieldbus 100. It supports configuration, diagnostics, and control with minimal downtime, making it a preferred choice in mission-critical operations.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | PM154 |

| Part Number | 3BSE003645R1 |

| Product Type | CPU Board / Central Processing Module |

| System Compatibility | Advant Controller 31 Series |

| Processor | High-speed 32-bit embedded processor |

| RAM Memory | 2 MB |

| Flash Memory | 1 MB |

| Supported Protocols | Advant Fieldbus 100, RS232, MODBUS |

| Execution Time | ≤ 1 ms per 1K instructions |

| Communication Ports | RS232, RS485, Advant Fieldbus |

| I/O Integration | Through S800 I/O or compatible modules |

| Mounting Method | DIN Rail or Rack Mounting |

| Operating Voltage | 5 VDC (supplied through base unit) |

| Power Consumption | Approx. 3.5 W |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5%–95% non-condensing |

| Protection Rating | IP20 |

| Dimensions (L × W × H) | 24 × 125 × 120 mm |

| Weight | 0.35 kg |

Applications

The ABB PM154 3BSE003645R1 is used across various industrial sectors due to its high reliability and performance capabilities:

-

Oil & Gas Industry – Used for pipeline control, compressor stations, and process safety systems.

-

Power Generation – Governs turbine control, boiler management, and auxiliary systems.

-

Metallurgy and Steel – Controls process furnaces, rolling mills, and automation lines.

-

Food & Beverage Processing – Handles batch processing, packaging, and conveyor control.

-

Pharmaceutical Manufacturing – Ensures GMP-compliant automation and data logging.

-

Water and Wastewater Treatment – Regulates valves, pumps, and chemical dosing systems.

Product Advantages

-

Enhanced Processing Capabilities – Delivers fast execution times for complex control logic.

-

High Memory Capacity – Offers larger RAM and flash than previous PM15x models, enabling robust program handling.

-

Multi-Protocol Communication – Built-in support for fieldbus communication ensures interoperability with various subsystems.

-

Compact Modular Design – Space-saving construction suitable for control cabinets and tight enclosures.

-

Advanced Diagnostics – Status LEDs and software-based tools provide real-time health and performance data.

-

Long-Term Availability – Part of ABB’s sustained product line, with long service life and ongoing support.

-

Scalable Architecture – Easily integrates with additional modules, supporting future expansion.

-

Secure and Stable Operation – Designed for continuous industrial operation with high EMI/RFI immunity.

-

Easy Integration – Compatible with standard ABB engineering tools for development and deployment.

-

Backward Compatibility – Designed to replace older PM15x modules without major system reconfiguration.

Frequently Asked Questions (FAQ)

-

What distinguishes the PM154 from the PM152 or PM151 modules?

The PM154 has a faster processor, increased memory, and improved communication interfaces, making it more suitable for demanding applications.

-

Which tools are used to configure and monitor the PM154?

ABB Control Builder and Composer tools are used for programming, diagnostics, and firmware updates.

-

Does PM154 support hot-swapping or online configuration?

While the CPU module itself is not hot-swappable, configuration changes can often be made without shutting down the entire system, depending on setup.

-

Is the PM154 suitable for high-speed data acquisition?

Yes, its enhanced processing and memory make it capable of managing high-frequency I/O operations and real-time data handling.

-

Can this CPU communicate with third-party devices?

Yes, using standard protocols like MODBUS or serial communication, it can interface with non-ABB equipment.

-

How is firmware managed for the PM154?

Firmware updates are managed through ABB’s software suite, typically via RS232 or fieldbus connections.

-

What’s the average lifespan of this module in industrial use?

Under normal operating conditions, it can function reliably for over 10 years with periodic maintenance.

-

Are there any specific grounding or shielding requirements?

Yes, for optimal performance, proper electrical grounding and shielding should be implemented as per ABB guidelines.

-

What happens during a CPU fault or failure?

The system transitions to a safe state, and diagnostics indicators or software logs help identify and correct the issue.

-

Is the PM154 certified for use in hazardous or safety-critical areas?

It is not inherently SIL-rated, but it can be part of a certified control system when integrated with appropriate safety components.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...