Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

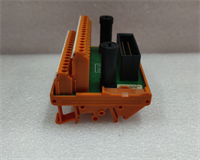

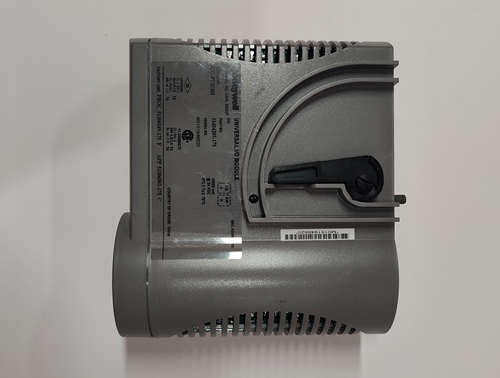

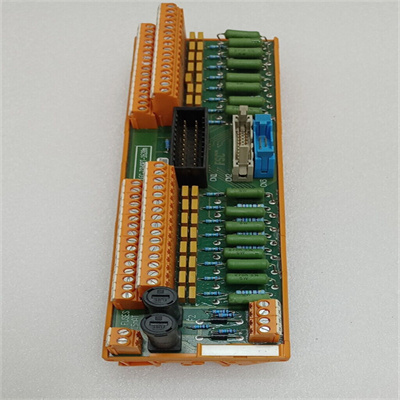

Honeywell FS-SCSBP212 Distribution Cable

Manufacturer:Honeywell

Product Number: FS-SCSBP212

Condition:Distribution Cable

Origin:USA

Cable length:1 m

Weight:0.5 kg

Views:52

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

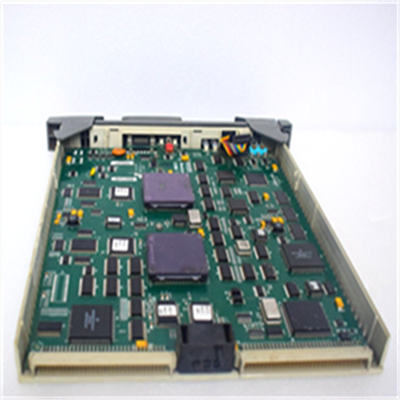

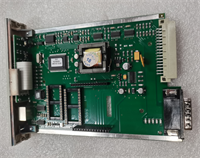

The Honeywell FS-SCSBP212 is a critical system backplane module designed for the Safety Manager Series within Honeywell’s renowned Fail Safe Controller (FSC) platform. It serves as a core component in safety-related control systems, offering high reliability and seamless integration within redundant or high-integrity architectures.

This backplane enables the interconnection of various I/O modules and processors, facilitating efficient communication and power distribution in a compact, structured format. With robust design standards, the FS-SCSBP212 is tailored for mission-critical applications, such as emergency shutdown (ESD), fire and gas (F&G), burner management systems (BMS), and more.

Its durability and industrial-grade construction allow it to withstand harsh operating environments, meeting stringent safety integrity level (SIL) requirements as part of a TÜV-certified safety solution.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | FS-SCSBP212 |

| Product Type | System Backplane for Safety Manager |

| Function | Signal and power distribution for I/O modules |

| Compatible Modules | FSC I/O cards, CPU cards, Power Supplies |

| Slot Configuration | 12 module slots |

| Mounting Type | Panel mounting (Horizontal or Vertical) |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Shock Resistance | 30G, 11ms |

| Vibration Resistance | 1.0G, 10–500Hz |

| Cable length | 1 m |

| Weight | 0.5 kg |

| Voltage Rating | Supports module power requirements (24 VDC) |

| Compliance | SIL3 (IEC 61508), CE, UL, TÜV |

| Material | High-grade industrial polymer and metal alloy |

Product Applications

The Honeywell FS-SCSBP212 is deployed across various safety and critical process environments. Its applications include:

-

Emergency Shutdown Systems (ESD) – Ensures immediate process halt during hazardous conditions.

-

Fire and Gas Detection (F&G) – Enables safe system response to fire or gas leaks.

-

Burner Management Systems (BMS) – Supports safe start-up, operation, and shutdown of burner units.

-

High-Integrity Pressure Protection Systems (HIPPS) – Provides rapid isolation in overpressure situations.

-

Refineries and Petrochemical Plants – For process safety layers in high-risk installations.

-

Power Generation Facilities – In turbine safety and boiler protection systems.

Product Advantages

-

Modular Expandability: Supports up to 12 modules, allowing customized I/O configurations based on project demands.

-

Industrial Durability: Built to withstand mechanical vibration, electrical noise, and thermal extremes.

-

Certified Safety: Fully compliant with SIL3 certification, ensuring it meets international safety standards.

-

Efficient Wiring and Maintenance: Structured layout and accessible slots improve ease of installation and reduce downtime.

-

High Reliability: Optimized for continuous operation in mission-critical settings with minimal failure risk.

-

Seamless Integration: Compatible with a wide range of Honeywell FSC modules, making system upgrades or replacements easy.

Frequently Asked Questions (FAQ)

Q1: What is the FS-SCSBP212 used for?

A1: It serves as the primary backplane in Honeywell Safety Manager systems, connecting power and signal lines between control modules.

Q2: How many modules can the FS-SCSBP212 support?

A2: It supports up to 12 modules in a single backplane configuration.

Q3: Is this backplane compatible with non-Honeywell modules?

A3: No, it is specifically designed for Honeywell FSC modules and may not function properly with third-party equipment.

Q4: What power voltage does the FS-SCSBP212 require?

A4: It typically operates with modules that require 24 VDC supplied via integrated or external power supplies.

Q5: What safety standards does this model meet?

A5: It meets IEC 61508 standards and is certified for SIL3 applications by TÜV.

Q6: Is it suitable for outdoor installation?

A6: Not directly. It must be installed within protective enclosures suitable for environmental conditions.

Q7: Can I use multiple FS-SCSBP212 backplanes in one system?

A7: Yes, systems requiring more I/O can use multiple interconnected backplanes.

Q8: How is the FS-SCSBP212 mounted?

A8: It is typically panel-mounted in a horizontal or vertical orientation inside control cabinets.

Q9: What happens if one module fails on the backplane?

A9: The design allows individual module replacement without affecting the rest of the system, supporting hot-swap in some cases.

Q10: Is there a standard maintenance schedule for this component?

A10: Regular inspections for dust accumulation, connector integrity, and thermal condition are advised, typically on a quarterly basis.

Honeywell FS-SCSBP212 Distribution Cable

Manufacturer:Honeywell

Product Number: FS-SCSBP212

Condition:Distribution Cable

Origin:USA

Cable length:1 m

Weight:0.5 kg

Views:52

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell FS-SCSBP212 is a critical system backplane module designed for the Safety Manager Series within Honeywell’s renowned Fail Safe Controller (FSC) platform. It serves as a core component in safety-related control systems, offering high reliability and seamless integration within redundant or high-integrity architectures.

This backplane enables the interconnection of various I/O modules and processors, facilitating efficient communication and power distribution in a compact, structured format. With robust design standards, the FS-SCSBP212 is tailored for mission-critical applications, such as emergency shutdown (ESD), fire and gas (F&G), burner management systems (BMS), and more.

Its durability and industrial-grade construction allow it to withstand harsh operating environments, meeting stringent safety integrity level (SIL) requirements as part of a TÜV-certified safety solution.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | FS-SCSBP212 |

| Product Type | System Backplane for Safety Manager |

| Function | Signal and power distribution for I/O modules |

| Compatible Modules | FSC I/O cards, CPU cards, Power Supplies |

| Slot Configuration | 12 module slots |

| Mounting Type | Panel mounting (Horizontal or Vertical) |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Shock Resistance | 30G, 11ms |

| Vibration Resistance | 1.0G, 10–500Hz |

| Cable length | 1 m |

| Weight | 0.5 kg |

| Voltage Rating | Supports module power requirements (24 VDC) |

| Compliance | SIL3 (IEC 61508), CE, UL, TÜV |

| Material | High-grade industrial polymer and metal alloy |

Product Applications

The Honeywell FS-SCSBP212 is deployed across various safety and critical process environments. Its applications include:

-

Emergency Shutdown Systems (ESD) – Ensures immediate process halt during hazardous conditions.

-

Fire and Gas Detection (F&G) – Enables safe system response to fire or gas leaks.

-

Burner Management Systems (BMS) – Supports safe start-up, operation, and shutdown of burner units.

-

High-Integrity Pressure Protection Systems (HIPPS) – Provides rapid isolation in overpressure situations.

-

Refineries and Petrochemical Plants – For process safety layers in high-risk installations.

-

Power Generation Facilities – In turbine safety and boiler protection systems.

Product Advantages

-

Modular Expandability: Supports up to 12 modules, allowing customized I/O configurations based on project demands.

-

Industrial Durability: Built to withstand mechanical vibration, electrical noise, and thermal extremes.

-

Certified Safety: Fully compliant with SIL3 certification, ensuring it meets international safety standards.

-

Efficient Wiring and Maintenance: Structured layout and accessible slots improve ease of installation and reduce downtime.

-

High Reliability: Optimized for continuous operation in mission-critical settings with minimal failure risk.

-

Seamless Integration: Compatible with a wide range of Honeywell FSC modules, making system upgrades or replacements easy.

Frequently Asked Questions (FAQ)

Q1: What is the FS-SCSBP212 used for?

A1: It serves as the primary backplane in Honeywell Safety Manager systems, connecting power and signal lines between control modules.

Q2: How many modules can the FS-SCSBP212 support?

A2: It supports up to 12 modules in a single backplane configuration.

Q3: Is this backplane compatible with non-Honeywell modules?

A3: No, it is specifically designed for Honeywell FSC modules and may not function properly with third-party equipment.

Q4: What power voltage does the FS-SCSBP212 require?

A4: It typically operates with modules that require 24 VDC supplied via integrated or external power supplies.

Q5: What safety standards does this model meet?

A5: It meets IEC 61508 standards and is certified for SIL3 applications by TÜV.

Q6: Is it suitable for outdoor installation?

A6: Not directly. It must be installed within protective enclosures suitable for environmental conditions.

Q7: Can I use multiple FS-SCSBP212 backplanes in one system?

A7: Yes, systems requiring more I/O can use multiple interconnected backplanes.

Q8: How is the FS-SCSBP212 mounted?

A8: It is typically panel-mounted in a horizontal or vertical orientation inside control cabinets.

Q9: What happens if one module fails on the backplane?

A9: The design allows individual module replacement without affecting the rest of the system, supporting hot-swap in some cases.

Q10: Is there a standard maintenance schedule for this component?

A10: Regular inspections for dust accumulation, connector integrity, and thermal condition are advised, typically on a quarterly basis.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...