Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

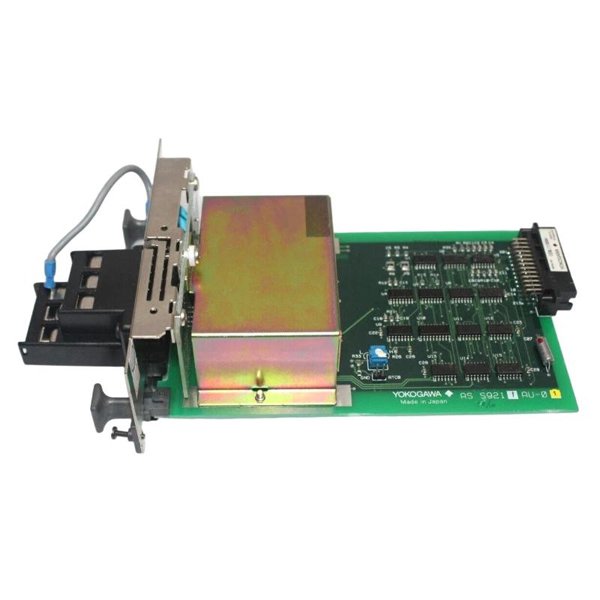

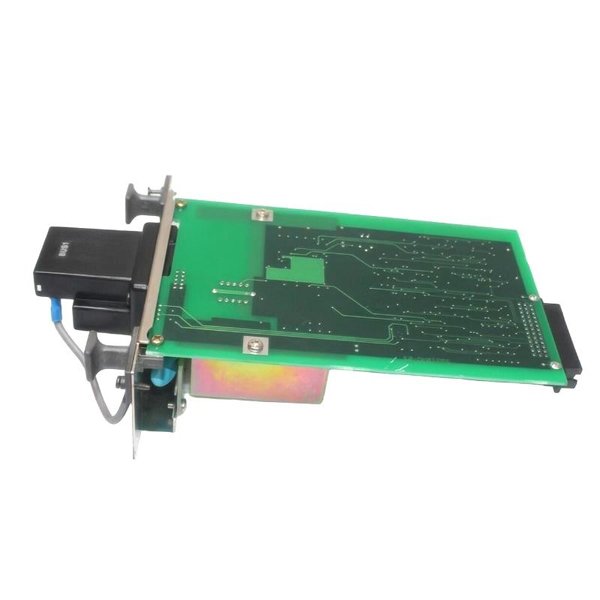

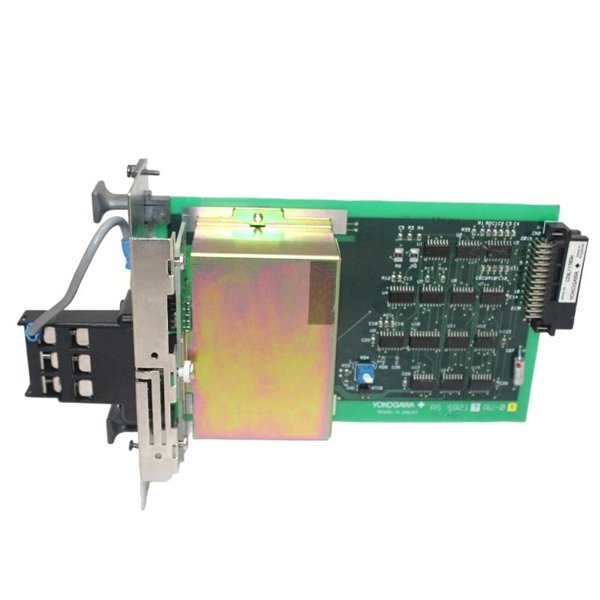

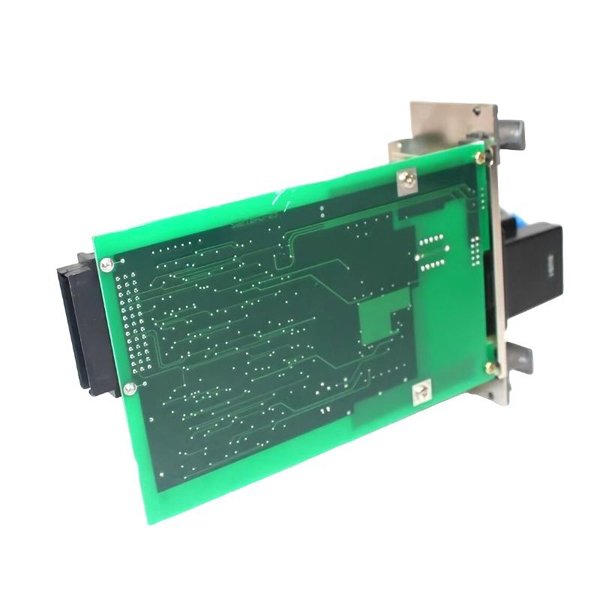

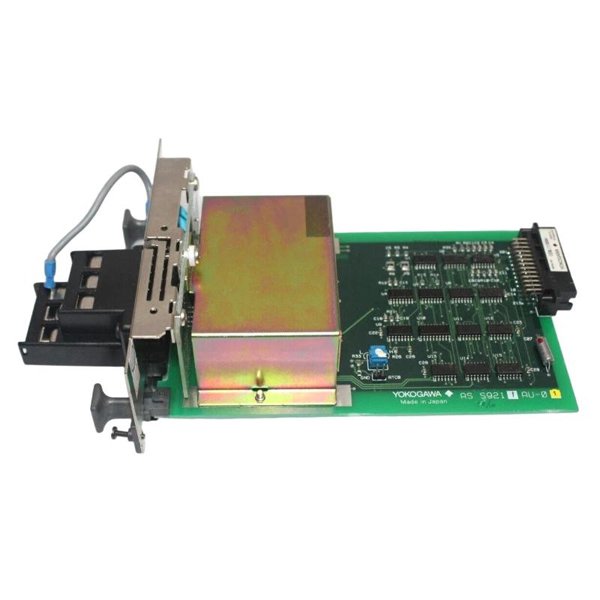

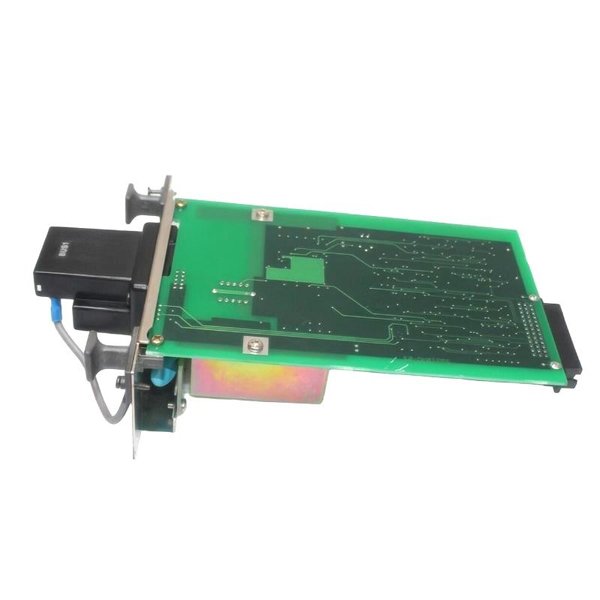

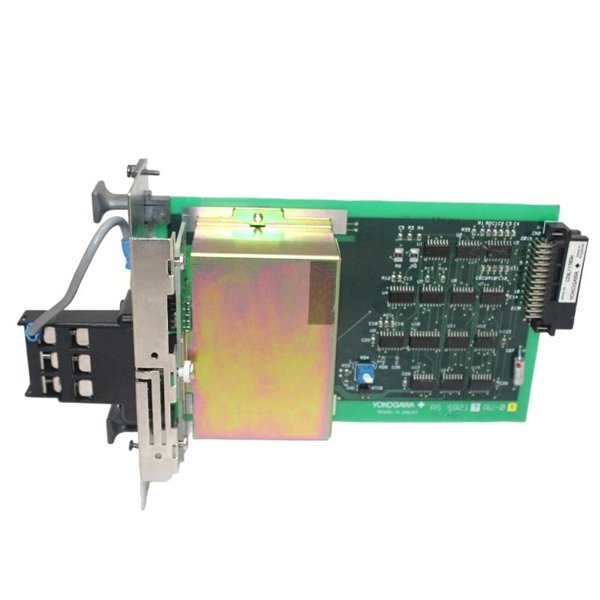

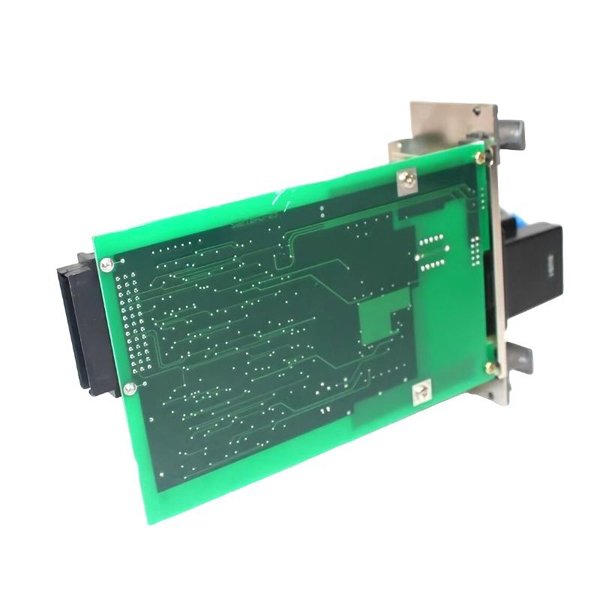

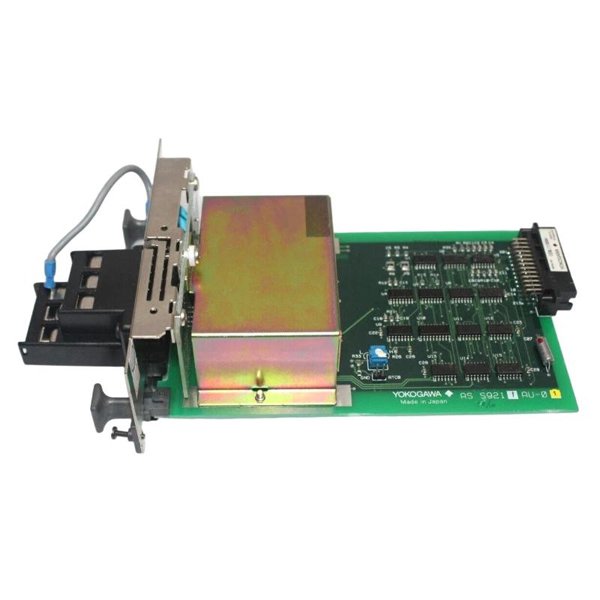

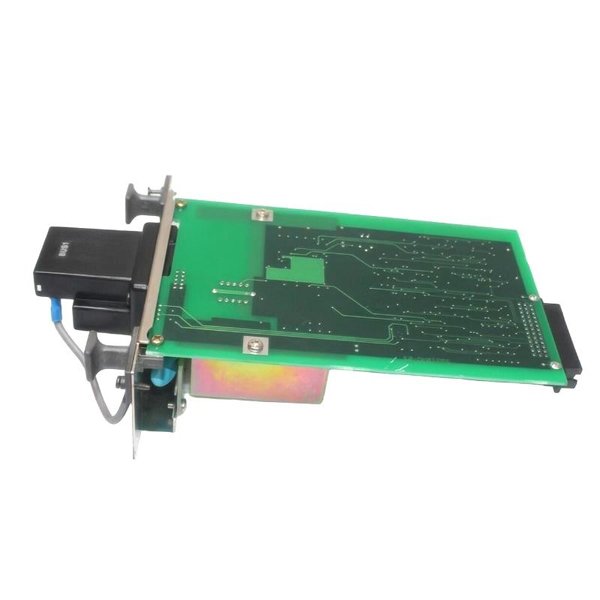

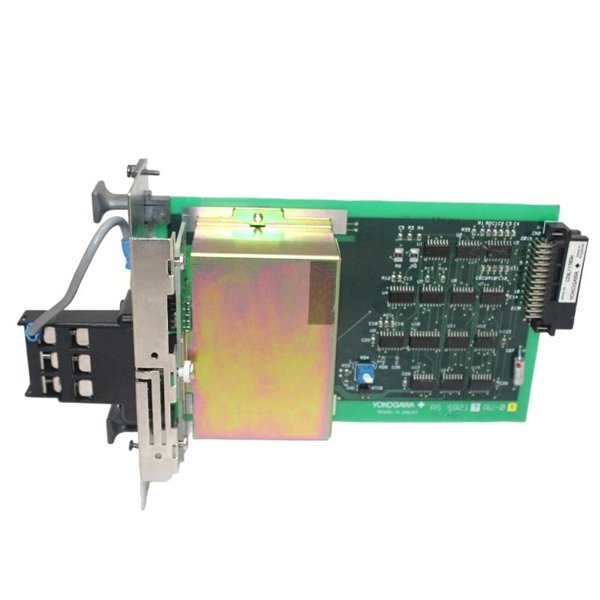

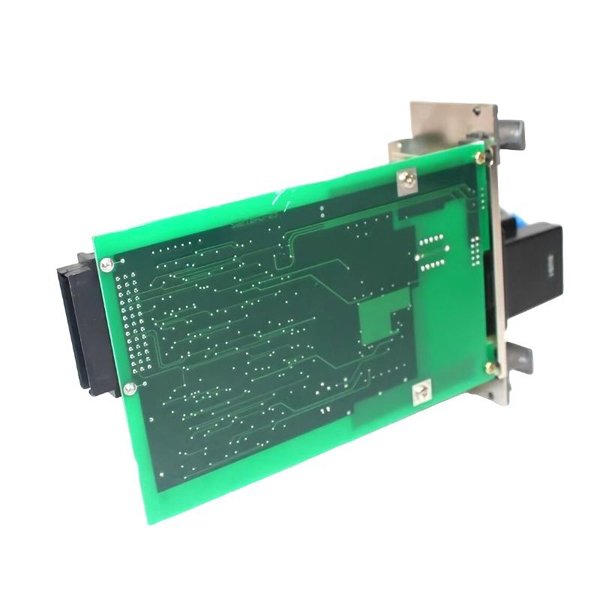

Yokogawa AIP581 Electrical Transceiver RIO I/O Module

Manufacturer:Yokogawa

Product Number:AIP581

Product Type:Electrical Transceiver RIO I/O Module

Origin:Japan

Dimensions:27 × 130 × 160 mm

Weight:0.45 kg

Views:107

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa AIP581 Electrical Transceiver RIO I/O Module is a high-performance component designed to provide reliable data communication and signal interfacing within distributed control systems (DCS). As part of the RIO (Remote Input/Output) architecture, this module facilitates efficient communication between field devices and the central control system, ensuring accurate signal conversion, transmission, and synchronization.

The AIP581 module is engineered for seamless integration with Yokogawa’s CENTUM VP and ProSafe-RS systems, offering superior interoperability, advanced error checking, and robust electrical isolation. It ensures high data integrity, low latency, and fault-tolerant operation, which are critical in mission-critical industries such as oil & gas, power generation, petrochemical, and advanced manufacturing.

Product Parameters

| Parameter | Description |

|---|---|

| Model | Yokogawa AIP581 Electrical Transceiver RIO I/O Module |

| Function | Electrical transceiver for RIO communication and I/O signal transmission |

| Supported Protocols | Proprietary RIO communication protocol (optimized for Yokogawa DCS/PLC) |

| Communication Medium | Electrical (copper wiring) |

| Data Transfer Rate | High-speed, deterministic transfer with error detection |

| Isolation | Electrical isolation between field and control system |

| Redundancy | Supports redundant configuration for high system availability |

| Power Supply | 24 V DC (nominal) |

| Power Consumption | Typically <10 W |

| Operating Temperature | 0 °C to +55 °C |

| Storage Temperature | -20 °C to +70 °C |

| Humidity | 5% to 95% RH (non-condensing) |

| Dimensions (W × H × D) | 27 × 130 × 160 mm |

| Weight | 0.45 kg |

Product Applications

The Yokogawa AIP581 module is widely applied in industries where reliable remote I/O communication and fast data exchange are crucial:

-

Oil & Gas: Used for upstream and downstream automation to ensure precise process monitoring and remote operation.

-

Power Generation: Ensures real-time control of turbine systems, boiler operations, and electrical networks.

-

Petrochemical & Refining: Provides reliable communication for distributed instrumentation and control in hazardous environments.

-

Pharmaceutical Manufacturing: Supports strict process control for compliance with regulatory requirements.

-

Water Treatment Plants: Manages distributed sensors and actuators to optimize water purification and distribution.

-

Heavy Manufacturing: Ensures seamless integration of field devices into supervisory control systems.

Product Advantages

-

High Reliability: Built with robust electrical isolation and redundancy support to guarantee system uptime.

-

Low Latency Communication: Ensures deterministic and real-time signal transfer between field devices and control units.

-

Scalability: Supports integration into large and complex distributed systems without performance degradation.

-

Error Detection & Correction: Advanced protocols minimize data loss and enhance communication integrity.

-

Easy Integration: Fully compatible with Yokogawa CENTUM VP and ProSafe-RS systems.

-

Long-Term Stability: Designed to withstand industrial environmental conditions, ensuring long service life.

FAQ

-

How does the AIP581 ensure communication integrity in noisy industrial environments?

The module employs error detection and correction protocols along with electrical isolation to maintain stable data transfer.

-

Can the AIP581 be configured in a redundant architecture?

Yes, it supports full redundancy to enhance system availability and fault tolerance.

-

Which Yokogawa systems are compatible with the AIP581?

It integrates seamlessly with CENTUM VP, ProSafe-RS, and other Yokogawa RIO-based architectures.

-

What type of communication medium does the AIP581 use?

It uses electrical (copper) wiring for RIO data transmission.

-

How is synchronization achieved between multiple I/O modules?

The module uses deterministic communication scheduling to ensure synchronized data exchange across the system.

-

Does the AIP581 support hot-swappable replacement?

Yes, it is designed for hot-swap capability, allowing maintenance without interrupting system operation.

-

What measures are in place to prevent data corruption during transfer?

The module applies CRC error checking and redundant transmission protocols.

-

How does the module handle communication failures?

It automatically switches to the redundant path and generates diagnostic alarms for operator awareness.

-

What is the maximum supported communication distance?

The distance depends on the RIO electrical interface specification, typically up to several hundred meters.

-

Can the AIP581 operate in hazardous area installations?

It can be used in hazardous zones when installed within certified enclosures or used with approved protection methods.

Yokogawa AIP581 Electrical Transceiver RIO I/O Module

Manufacturer:Yokogawa

Product Number:AIP581

Product Type:Electrical Transceiver RIO I/O Module

Origin:Japan

Dimensions:27 × 130 × 160 mm

Weight:0.45 kg

Views:107

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Yokogawa AIP581 Electrical Transceiver RIO I/O Module is a high-performance component designed to provide reliable data communication and signal interfacing within distributed control systems (DCS). As part of the RIO (Remote Input/Output) architecture, this module facilitates efficient communication between field devices and the central control system, ensuring accurate signal conversion, transmission, and synchronization.

The AIP581 module is engineered for seamless integration with Yokogawa’s CENTUM VP and ProSafe-RS systems, offering superior interoperability, advanced error checking, and robust electrical isolation. It ensures high data integrity, low latency, and fault-tolerant operation, which are critical in mission-critical industries such as oil & gas, power generation, petrochemical, and advanced manufacturing.

Product Parameters

| Parameter | Description |

|---|---|

| Model | Yokogawa AIP581 Electrical Transceiver RIO I/O Module |

| Function | Electrical transceiver for RIO communication and I/O signal transmission |

| Supported Protocols | Proprietary RIO communication protocol (optimized for Yokogawa DCS/PLC) |

| Communication Medium | Electrical (copper wiring) |

| Data Transfer Rate | High-speed, deterministic transfer with error detection |

| Isolation | Electrical isolation between field and control system |

| Redundancy | Supports redundant configuration for high system availability |

| Power Supply | 24 V DC (nominal) |

| Power Consumption | Typically <10 W |

| Operating Temperature | 0 °C to +55 °C |

| Storage Temperature | -20 °C to +70 °C |

| Humidity | 5% to 95% RH (non-condensing) |

| Dimensions (W × H × D) | 27 × 130 × 160 mm |

| Weight | 0.45 kg |

Product Applications

The Yokogawa AIP581 module is widely applied in industries where reliable remote I/O communication and fast data exchange are crucial:

-

Oil & Gas: Used for upstream and downstream automation to ensure precise process monitoring and remote operation.

-

Power Generation: Ensures real-time control of turbine systems, boiler operations, and electrical networks.

-

Petrochemical & Refining: Provides reliable communication for distributed instrumentation and control in hazardous environments.

-

Pharmaceutical Manufacturing: Supports strict process control for compliance with regulatory requirements.

-

Water Treatment Plants: Manages distributed sensors and actuators to optimize water purification and distribution.

-

Heavy Manufacturing: Ensures seamless integration of field devices into supervisory control systems.

Product Advantages

-

High Reliability: Built with robust electrical isolation and redundancy support to guarantee system uptime.

-

Low Latency Communication: Ensures deterministic and real-time signal transfer between field devices and control units.

-

Scalability: Supports integration into large and complex distributed systems without performance degradation.

-

Error Detection & Correction: Advanced protocols minimize data loss and enhance communication integrity.

-

Easy Integration: Fully compatible with Yokogawa CENTUM VP and ProSafe-RS systems.

-

Long-Term Stability: Designed to withstand industrial environmental conditions, ensuring long service life.

FAQ

-

How does the AIP581 ensure communication integrity in noisy industrial environments?

The module employs error detection and correction protocols along with electrical isolation to maintain stable data transfer.

-

Can the AIP581 be configured in a redundant architecture?

Yes, it supports full redundancy to enhance system availability and fault tolerance.

-

Which Yokogawa systems are compatible with the AIP581?

It integrates seamlessly with CENTUM VP, ProSafe-RS, and other Yokogawa RIO-based architectures.

-

What type of communication medium does the AIP581 use?

It uses electrical (copper) wiring for RIO data transmission.

-

How is synchronization achieved between multiple I/O modules?

The module uses deterministic communication scheduling to ensure synchronized data exchange across the system.

-

Does the AIP581 support hot-swappable replacement?

Yes, it is designed for hot-swap capability, allowing maintenance without interrupting system operation.

-

What measures are in place to prevent data corruption during transfer?

The module applies CRC error checking and redundant transmission protocols.

-

How does the module handle communication failures?

It automatically switches to the redundant path and generates diagnostic alarms for operator awareness.

-

What is the maximum supported communication distance?

The distance depends on the RIO electrical interface specification, typically up to several hundred meters.

-

Can the AIP581 operate in hazardous area installations?

It can be used in hazardous zones when installed within certified enclosures or used with approved protection methods.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...