Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

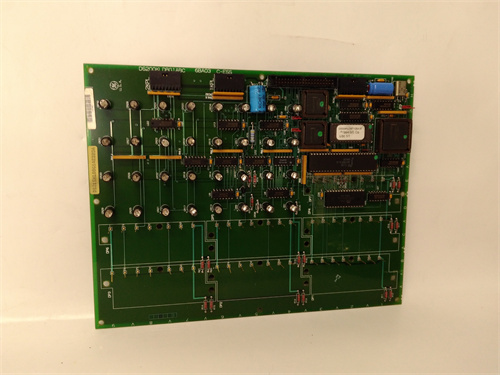

General Electric Fanuc IS230TCISH6C Controller Module

Manufacturer:GE Fanu

Product Number:IS230TCISH6C

Product Type:Controller Module

Origin:USA

Dimensions:250 × 200 × 100 mm

Weight:2.5kg

Views:162

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE Fanuc IS230TCISH6C Controller Module is a high-performance control module designed for GE Mark VIe turbine control systems. It provides real-time processing, secure communication, and advanced fault detection to ensure efficient and reliable turbine operations.

Key Features

-

High-speed real-time processing for turbine and process control

-

Supports redundant operation for maximum system reliability

-

Advanced self-diagnostics and fault-tolerant design

-

Ethernet and proprietary GE turbine communication interfaces

-

Compact, rugged design suitable for rack-mounted installations

-

Seamless integration with GE Mark VIe I/O and communication modules

-

Optimized for harsh industrial and power generation environments

Technical Specifications

| Item | Specification |

|---|---|

| Model Number | IS230TCISH6C |

| Type | Controller Module |

| System Compatibility | GE Mark VIe Turbine Control System |

| Function | Centralized control and communication for turbine systems |

| Processing | High-speed real-time processor |

| Communication | Ethernet, proprietary GE turbine control protocols |

| Input Voltage | 28 VDC nominal |

| Power Consumption | Optimized for low power usage |

| Reliability | Redundant operation support |

| Operating Temperature | -40 °C to +70 °C |

| Storage Temperature | -50 °C to +85 °C |

| Humidity | 5–95% non-condensing |

| Dimensions | 250 × 200 × 100 mm |

| Weight | 2.5 kg |

| Mounting | Rack-mounted in Mark VIe control panel |

| Cooling | Passive convection |

| Compliance | CE, RoHS, UL certified |

Industry Applications

-

Steam turbine automation

-

Power generation distributed control systems (DCS)

-

Oil & gas process automation and turbine control

-

Industrial manufacturing requiring high-availability control systems

-

Safety-critical turbine monitoring systems

Advantages

-

Provides robust real-time control for critical turbine applications

-

Supports redundant operation to minimize downtime

-

Built-in self-diagnostics and fault detection enhance system reliability

-

Compact and rack-mounted for easy installation and maintenance

-

Compatible with GE Mark VIe system modules for seamless integration

-

Rugged design ensures long-term operation in industrial environments

Frequently Asked Questions (FAQ)

Q1: What is the main function of the IS230TCISH6C?

It serves as the primary controller, managing turbine operations and communication in the Mark VIe system.

Q2: Can this module operate in redundant mode?

Yes, it is designed to support redundant configurations.

Q3: What communication interfaces does it support?

Ethernet and GE proprietary turbine control protocols.

Q4: What is the operating temperature range?

-40 °C to +70 °C.

Q5: Is the module hot-swappable?

Yes, in redundant configurations hot-swapping may be supported.

Q6: What industries commonly use this module?

Power generation, oil & gas, petrochemical, and heavy industrial processes.

Q7: How is the module installed?

It is rack-mounted within the Mark VIe control panel.

Q8: What diagnostics are included?

Self-diagnostics, fault detection, and error reporting are included.

Q9: What are the module’s dimensions and weight?

Dimensions are 250 × 200 × 100 mm; weight are 2.5 kg.

Q10: Why is this module reliable for turbine control?

Its high-speed processing, fault-tolerant design, and robust architecture ensure reliable and secure turbine operations.

General Electric Fanuc IS230TCISH6C Controller Module

Manufacturer:GE Fanu

Product Number:IS230TCISH6C

Product Type:Controller Module

Origin:USA

Dimensions:250 × 200 × 100 mm

Weight:2.5kg

Views:162

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE Fanuc IS230TCISH6C Controller Module is a high-performance control module designed for GE Mark VIe turbine control systems. It provides real-time processing, secure communication, and advanced fault detection to ensure efficient and reliable turbine operations.

Key Features

-

High-speed real-time processing for turbine and process control

-

Supports redundant operation for maximum system reliability

-

Advanced self-diagnostics and fault-tolerant design

-

Ethernet and proprietary GE turbine communication interfaces

-

Compact, rugged design suitable for rack-mounted installations

-

Seamless integration with GE Mark VIe I/O and communication modules

-

Optimized for harsh industrial and power generation environments

Technical Specifications

| Item | Specification |

|---|---|

| Model Number | IS230TCISH6C |

| Type | Controller Module |

| System Compatibility | GE Mark VIe Turbine Control System |

| Function | Centralized control and communication for turbine systems |

| Processing | High-speed real-time processor |

| Communication | Ethernet, proprietary GE turbine control protocols |

| Input Voltage | 28 VDC nominal |

| Power Consumption | Optimized for low power usage |

| Reliability | Redundant operation support |

| Operating Temperature | -40 °C to +70 °C |

| Storage Temperature | -50 °C to +85 °C |

| Humidity | 5–95% non-condensing |

| Dimensions | 250 × 200 × 100 mm |

| Weight | 2.5 kg |

| Mounting | Rack-mounted in Mark VIe control panel |

| Cooling | Passive convection |

| Compliance | CE, RoHS, UL certified |

Industry Applications

-

Steam turbine automation

-

Power generation distributed control systems (DCS)

-

Oil & gas process automation and turbine control

-

Industrial manufacturing requiring high-availability control systems

-

Safety-critical turbine monitoring systems

Advantages

-

Provides robust real-time control for critical turbine applications

-

Supports redundant operation to minimize downtime

-

Built-in self-diagnostics and fault detection enhance system reliability

-

Compact and rack-mounted for easy installation and maintenance

-

Compatible with GE Mark VIe system modules for seamless integration

-

Rugged design ensures long-term operation in industrial environments

Frequently Asked Questions (FAQ)

Q1: What is the main function of the IS230TCISH6C?

It serves as the primary controller, managing turbine operations and communication in the Mark VIe system.

Q2: Can this module operate in redundant mode?

Yes, it is designed to support redundant configurations.

Q3: What communication interfaces does it support?

Ethernet and GE proprietary turbine control protocols.

Q4: What is the operating temperature range?

-40 °C to +70 °C.

Q5: Is the module hot-swappable?

Yes, in redundant configurations hot-swapping may be supported.

Q6: What industries commonly use this module?

Power generation, oil & gas, petrochemical, and heavy industrial processes.

Q7: How is the module installed?

It is rack-mounted within the Mark VIe control panel.

Q8: What diagnostics are included?

Self-diagnostics, fault detection, and error reporting are included.

Q9: What are the module’s dimensions and weight?

Dimensions are 250 × 200 × 100 mm; weight are 2.5 kg.

Q10: Why is this module reliable for turbine control?

Its high-speed processing, fault-tolerant design, and robust architecture ensure reliable and secure turbine operations.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...