Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

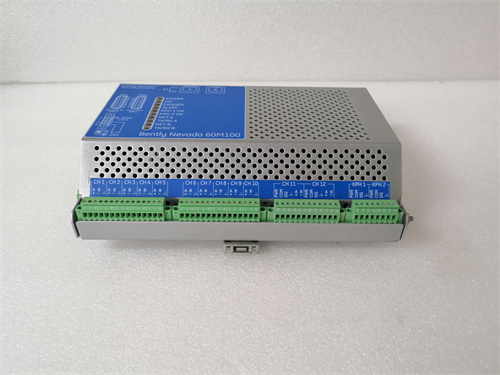

Bently Nevada 3500/42 125672-02 Proximity Seismic Monitor

Brand: Bently Nevada

Model Number:3500/42 125672-02

Type:Proximity Seismic Monitor

Product Origin: USA

Payment: T/T, Western Union, Credit Card

Dimensions: 10cm x 10cm x 4cm

Shipping Weight:0.5 Kg

Price: USD500

Certificate: CE

Warranty: 1 years

Product Description

The Bently Nevada 3500/42 125672-02 is a robust four-channel proximity/seismic monitor designed for industrial applications, particularly in monitoring machinery vibration and position. It is part of the Bently Nevada 3500 Monitoring System, known for its reliability in harsh environments.

Specifications

- Number of Channels: 4

- Input Types: Proximity or seismic transducers

- Signal Conditioning: Displacement, velocity, acceleration, phase, proximity, and bearing wear

- Alarms: User-programmable alarms

- Outputs: Analog and digital outputs

- Communication: Ethernet, RS-485

- Environmental Rating: NEMA 4/IP66, -40 to 80°C (-40 to 176°F), 0 to 95% RH (non-condensing)

Applications

- Pump Monitoring: Detecting bearing wear, cavitation, and other issues.

- Compressor Monitoring: Monitoring vibration to detect bearing wear, valve problems, etc.

- Turbine Monitoring: Detecting bearing wear, blade wear, and other turbine issues.

- Gearbox Monitoring: Monitoring vibration for bearing wear, gear wear, etc.

- Motor Monitoring: Detecting bearing wear, stator faults, and other motor issues.

Benefits

- Improved Machinery Reliability: Early detection of problems prevents unplanned downtime and extends machinery life.

- Reduced Maintenance Costs: Provides condition data for efficient maintenance scheduling.

- Enhanced Safety: Early detection of dangerous conditions helps prevent accidents.

- Increased Productivity: Reduced downtime and improved reliability contribute to higher productivity.

Bently Nevada 3500/42 125672-02 Proximity Seismic Monitor

Brand: Bently Nevada

Model Number:3500/42 125672-02

Type:Proximity Seismic Monitor

Product Origin: USA

Payment: T/T, Western Union, Credit Card

Dimensions: 10cm x 10cm x 4cm

Shipping Weight:0.5 Kg

Price: USD500

Certificate: CE

Warranty: 1 years

Product Description

The Bently Nevada 3500/42 125672-02 is a robust four-channel proximity/seismic monitor designed for industrial applications, particularly in monitoring machinery vibration and position. It is part of the Bently Nevada 3500 Monitoring System, known for its reliability in harsh environments.

Specifications

- Number of Channels: 4

- Input Types: Proximity or seismic transducers

- Signal Conditioning: Displacement, velocity, acceleration, phase, proximity, and bearing wear

- Alarms: User-programmable alarms

- Outputs: Analog and digital outputs

- Communication: Ethernet, RS-485

- Environmental Rating: NEMA 4/IP66, -40 to 80°C (-40 to 176°F), 0 to 95% RH (non-condensing)

Applications

- Pump Monitoring: Detecting bearing wear, cavitation, and other issues.

- Compressor Monitoring: Monitoring vibration to detect bearing wear, valve problems, etc.

- Turbine Monitoring: Detecting bearing wear, blade wear, and other turbine issues.

- Gearbox Monitoring: Monitoring vibration for bearing wear, gear wear, etc.

- Motor Monitoring: Detecting bearing wear, stator faults, and other motor issues.

Benefits

- Improved Machinery Reliability: Early detection of problems prevents unplanned downtime and extends machinery life.

- Reduced Maintenance Costs: Provides condition data for efficient maintenance scheduling.

- Enhanced Safety: Early detection of dangerous conditions helps prevent accidents.

- Increased Productivity: Reduced downtime and improved reliability contribute to higher productivity.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...