Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

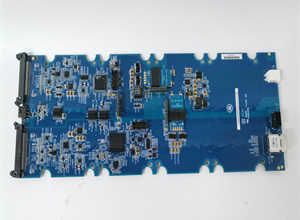

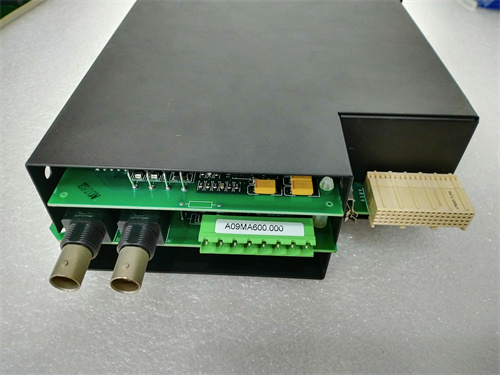

GE Fanuc DS200TCTGG1AFF Numerical Control System

Manufacturer:General Electric

Part Number:DS200TCTGG1AFF

Product Type:Numerical Control System

Series:GE Speedtronic Mark V

Stock:IN STOCK

Repair:3-7 Day

Rush Repair:24-48 Hrs.

Warranty:3 Years

Dimensions:812 x 516 x 825 mm

Weight:0.91kg

Product Description

The GE Fanuc DS200TCTGG1AFF is a high-performance numerical control (NC) system designed for advanced manufacturing. This system is part of GE Fanuc’s comprehensive automation solutions, known for reliability, precision, and flexibility. It meets the demanding requirements of industries such as automotive, aerospace, and machine tool manufacturing.

Advanced CNC Technology

The DS200TCTGG1AFF incorporates cutting-edge CNC technology. It enhances machining capabilities and boosts productivity.

High-Speed Processing

This NC system processes at high speed, reducing cycle times and manufacturing lead times.

Enhanced Accuracy

Advanced motion control algorithms ensure the DS200TCTGG1AFF delivers exceptional accuracy and repeatability in machining operations.

Flexible Programming

The system supports various programming languages and formats. This flexibility simplifies programming tasks.

Integration Capabilities

The DS200TCTGG1AFF integrates seamlessly with various peripherals and automation components. This integration helps create comprehensive manufacturing solutions.

Reliability and Durability

Built for harsh industrial environments, the DS200TCTGG1AFF offers long-term reliability and minimal downtime.

Applications

The GE Fanuc DS200TCTGG1AFF excels in various applications, including:

- Milling: Perform high-precision milling for complex parts.

- Turning: Efficiently turn cylindrical and contoured parts.

- Drilling: Execute accurate drilling and tapping operations.

- Grinding: Achieve precision grinding for surface finishing.

GE Fanuc DS200TCTGG1AFF Numerical Control System

Manufacturer:General Electric

Part Number:DS200TCTGG1AFF

Product Type:Numerical Control System

Series:GE Speedtronic Mark V

Stock:IN STOCK

Repair:3-7 Day

Rush Repair:24-48 Hrs.

Warranty:3 Years

Dimensions:812 x 516 x 825 mm

Weight:0.91kg

Product Description

The GE Fanuc DS200TCTGG1AFF is a high-performance numerical control (NC) system designed for advanced manufacturing. This system is part of GE Fanuc’s comprehensive automation solutions, known for reliability, precision, and flexibility. It meets the demanding requirements of industries such as automotive, aerospace, and machine tool manufacturing.

Advanced CNC Technology

The DS200TCTGG1AFF incorporates cutting-edge CNC technology. It enhances machining capabilities and boosts productivity.

High-Speed Processing

This NC system processes at high speed, reducing cycle times and manufacturing lead times.

Enhanced Accuracy

Advanced motion control algorithms ensure the DS200TCTGG1AFF delivers exceptional accuracy and repeatability in machining operations.

Flexible Programming

The system supports various programming languages and formats. This flexibility simplifies programming tasks.

Integration Capabilities

The DS200TCTGG1AFF integrates seamlessly with various peripherals and automation components. This integration helps create comprehensive manufacturing solutions.

Reliability and Durability

Built for harsh industrial environments, the DS200TCTGG1AFF offers long-term reliability and minimal downtime.

Applications

The GE Fanuc DS200TCTGG1AFF excels in various applications, including:

- Milling: Perform high-precision milling for complex parts.

- Turning: Efficiently turn cylindrical and contoured parts.

- Drilling: Execute accurate drilling and tapping operations.

- Grinding: Achieve precision grinding for surface finishing.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...