Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

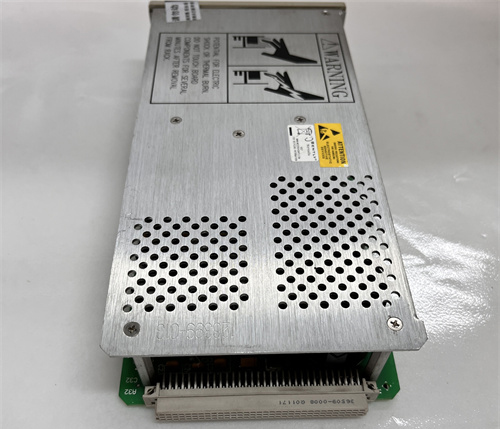

Bently Nevada 3500/05-02-04-00-00 Framework Vibration Monitor

Module Number:3500/05-02-04-00-00

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

The BENTLY 3500/05-02-04-00-00 framework is a highly modular instrument framework produced by Bently Nevada in the United States. This product is typically used as part of a vibration monitoring system and is widely used in vibration monitoring and mechanical integrity assessment of industrial equipment and machinery. The following is a detailed analysis of the framework.

Product Overview

Brand and Manufacturer: BENTLY, also known as Bently Nevada, is a brand under Schneider Electric, specializing in the field of mechanical integrity monitoring and control.

Model: 3500/05-02-04-00-00

Usage: Mainly used to monitor the vibration, temperature, speed, and other key parameters of rotating machinery, in order to detect faults in advance and prevent equipment shutdown.

Product features

This framework has a highly modular design, including various modules such as instrument framework, power supply, framework interface module, keyphasor module, monitor module, etc.

This design makes the product easy to install, configure, and maintain.

Monitoring function:

Equipped with vibration monitoring module, temperature monitoring module, and speed monitoring module, it can monitor the operating status of the equipment in real time.

Capable of detecting abnormal vibration patterns, temperature anomalies, and abnormal speed conditions to identify potential mechanical faults.

Data processing and transmission:

Equipped with data acquisition and transmission functions, it can transmit vibration, temperature, speed and other data to the central data acquisition system.

Support multiple protocols to synchronize vibration and process information, improving the efficiency and accuracy of data transmission.

Alarm and notification:

When an abnormality is detected, an alarm function will be triggered and a notification will be sent to the operation and maintenance personnel.

This helps operation and maintenance personnel to promptly detect and take measures to avoid equipment failures and shutdowns.

Cost savings:

Provide various cost saving features, such as reducing wiring costs, improving space utilization, facilitating configuration, reducing spare parts, and improving serviceability.

Sensitivity and frequency response:

Has high sensitivity and frequency response range, and can accurately monitor the operating status of equipment.

For example, at 100 Hz (6000 cpm), its sensitivity is 20mV/mm/s (500 mV/in/s) ± 5%, and the frequency response range is from the operating frequency to 1 kHz (60000 cpm).

Application field

The BENTLY 3500/05-02-04-00-00 framework is widely used for mechanical condition monitoring of rotating equipment in various industries, including but not limited to:

Oil and gas production

Hydroelectric power generation

Wind energy

Hydrocarbon treatment

electricity generation

Pulp and paper

mining

Water and wastewater treatment, etc

It can play an important role in mechanical protection applications that require continuous and online monitoring, such as vibration and displacement measurement of oil film bearing machinery, as well as key phase and speed measurement.

Summary

The BENTLY 3500/05-02-04-00-00 framework plays an important role in the vibration monitoring and mechanical integrity assessment of industrial equipment and machinery due to its modular design, powerful monitoring functions, efficient data processing and transmission capabilities, timely alarm and notification mechanisms, and high sensitivity and frequency response range. Meanwhile, its wide range of applications has also proven its practicality and reliability in different industries.

Bently Nevada 3500/05-02-04-00-00 Framework Vibration Monitor

Module Number:3500/05-02-04-00-00

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

The BENTLY 3500/05-02-04-00-00 framework is a highly modular instrument framework produced by Bently Nevada in the United States. This product is typically used as part of a vibration monitoring system and is widely used in vibration monitoring and mechanical integrity assessment of industrial equipment and machinery. The following is a detailed analysis of the framework.

Product Overview

Brand and Manufacturer: BENTLY, also known as Bently Nevada, is a brand under Schneider Electric, specializing in the field of mechanical integrity monitoring and control.

Model: 3500/05-02-04-00-00

Usage: Mainly used to monitor the vibration, temperature, speed, and other key parameters of rotating machinery, in order to detect faults in advance and prevent equipment shutdown.

Product features

This framework has a highly modular design, including various modules such as instrument framework, power supply, framework interface module, keyphasor module, monitor module, etc.

This design makes the product easy to install, configure, and maintain.

Monitoring function:

Equipped with vibration monitoring module, temperature monitoring module, and speed monitoring module, it can monitor the operating status of the equipment in real time.

Capable of detecting abnormal vibration patterns, temperature anomalies, and abnormal speed conditions to identify potential mechanical faults.

Data processing and transmission:

Equipped with data acquisition and transmission functions, it can transmit vibration, temperature, speed and other data to the central data acquisition system.

Support multiple protocols to synchronize vibration and process information, improving the efficiency and accuracy of data transmission.

Alarm and notification:

When an abnormality is detected, an alarm function will be triggered and a notification will be sent to the operation and maintenance personnel.

This helps operation and maintenance personnel to promptly detect and take measures to avoid equipment failures and shutdowns.

Cost savings:

Provide various cost saving features, such as reducing wiring costs, improving space utilization, facilitating configuration, reducing spare parts, and improving serviceability.

Sensitivity and frequency response:

Has high sensitivity and frequency response range, and can accurately monitor the operating status of equipment.

For example, at 100 Hz (6000 cpm), its sensitivity is 20mV/mm/s (500 mV/in/s) ± 5%, and the frequency response range is from the operating frequency to 1 kHz (60000 cpm).

Application field

The BENTLY 3500/05-02-04-00-00 framework is widely used for mechanical condition monitoring of rotating equipment in various industries, including but not limited to:

Oil and gas production

Hydroelectric power generation

Wind energy

Hydrocarbon treatment

electricity generation

Pulp and paper

mining

Water and wastewater treatment, etc

It can play an important role in mechanical protection applications that require continuous and online monitoring, such as vibration and displacement measurement of oil film bearing machinery, as well as key phase and speed measurement.

Summary

The BENTLY 3500/05-02-04-00-00 framework plays an important role in the vibration monitoring and mechanical integrity assessment of industrial equipment and machinery due to its modular design, powerful monitoring functions, efficient data processing and transmission capabilities, timely alarm and notification mechanisms, and high sensitivity and frequency response range. Meanwhile, its wide range of applications has also proven its practicality and reliability in different industries.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...